Abstract

To establish battery electric vehicles as an attractive alternative to internal combustion vehicles, charging times of 15 min or less are increasingly demanded. This is especially challenging for lower battery temperatures, as this exacerbates the risk of accelerated battery degradation due to lithium plating. Therefore, active battery heating is utilized in state-of-the-art electric vehicles. To evaluate the impact of such heating strategies at vehicle level, we deployed an electrochemical battery model coupled with a longitudinal vehicle dynamics model. Using anode potential control to prevent lithium plating, we assess the time-saving potential versus the energy cost of different preconditioning and fast-charging strategies. The results reveal substantial energy saving and charge speed increase potential through optimal charge-stop planning, preconditioning timing, cost-adjusted thermal management thresholds, and considering driving behavior. This emphasizes the need for advanced operation strategies, taking into account both battery-level electrical and thermal restrictions, as well as vehicle integration and route planning.

1. Introduction

Although current-generation electric vehicles offer increasing charging speeds, achieving the often-demanded charging time of 15 min or less to charge from 10% to 80% state-of-charge (SOC) remains challenging due to several technological barriers from materials to the system level [1]. One main limiting factor is lithium plating, which has a higher risk of occurring at lower temperatures, high SOCs, and high charging rates [2]. As plating only occurs with negative anode potentials, suitable battery models can be deployed to perform model-based fast-charging, which has been demonstrated to permit faster charging with reduced battery degradation [3,4,5]. Due to the highly coupled nature of the electrical and thermal effects within lithium-ion batteries, recent studies have, however, shown that fast-charging requires suitable heating and cooling strategies to achieve shorter charge durations while taking battery self-heating and safety limitations into account [6]. In particular, cold ambient conditions lead to a considerable deterioration in electric vehicle fast-charging capabilities [7].

While this has been examined at the cell level in several publications [8,9,10], applying such fast-charging and preconditioning strategies to the vehicle level poses additional challenges [11], stemming from greater thermal constraints and the required energy consumption and cost considerations [12]. These need to be coupled with infrastructure constraints [13] and vehicle design factors, such as application-specific dimensioning of the thermal management system [14] or the battery system and vehicle electrical architecture [15]. Previous charging and heating strategies are furthermore usually based on complex models and nonlinear optimization methodologies [3,16,17,18], which could be challenging within vehicle applications due to limited computation resources, necessitating simplified approaches and generalized operation guidelines. While some previous examinations have integrated models to derive vehicle-level operation strategies to optimize energy consumption, charging time, and travel duration, these are based on simplified-battery-equivalent circuit models that do not offer insight into lithium plating behavior and the resulting fast-charging capability [19,20,21,22], or focus mainly on cooling [23].

Optimized thermal management strategies, in particular, have been demonstrated to offer improvement potential, but need to be coupled with a prediction of the battery behavior to be implemented in real-world applications [24]. This could be particularly attractive for commercial use cases, in which the route and driving behavior are usually known in advance [25], although approaches exist that also take route uncertainties into account [26]. While heating may offer benefits regarding charging speeds, high temperatures also pose a risk regarding accelerated aging due to side reactions and safety, which also necessitates an appropriate cooling strategy [27].

To our knowledge, the application of model-based fast-charging to derive vehicle-level operation strategies has not been examined in previous studies. This is particularly interesting, as observed driver behavior often contradicts recommended best practices for lithium-ion battery fast-charging [28,29]. While the highest charging currents can be achieved at lower starting SOCs [9], past surveys and field data evaluations have indicated that range anxiety leads a large portion of drivers to fast-charge at SOCs higher than 30% [30]. This increase in range anxiety is especially pronounced at low ambient temperatures [30]. As achievable charging rates grow, users increasingly tend towards lower charging-stop SOCs [31], which may improve overall charging speed and efficiency. By deploying electrochemical battery models coupled with thermal behavior and integrating them into vehicle examinations, a physics-based derivation of optimal fast-charging and thermal management strategies can be achieved.

1.1. Contributions

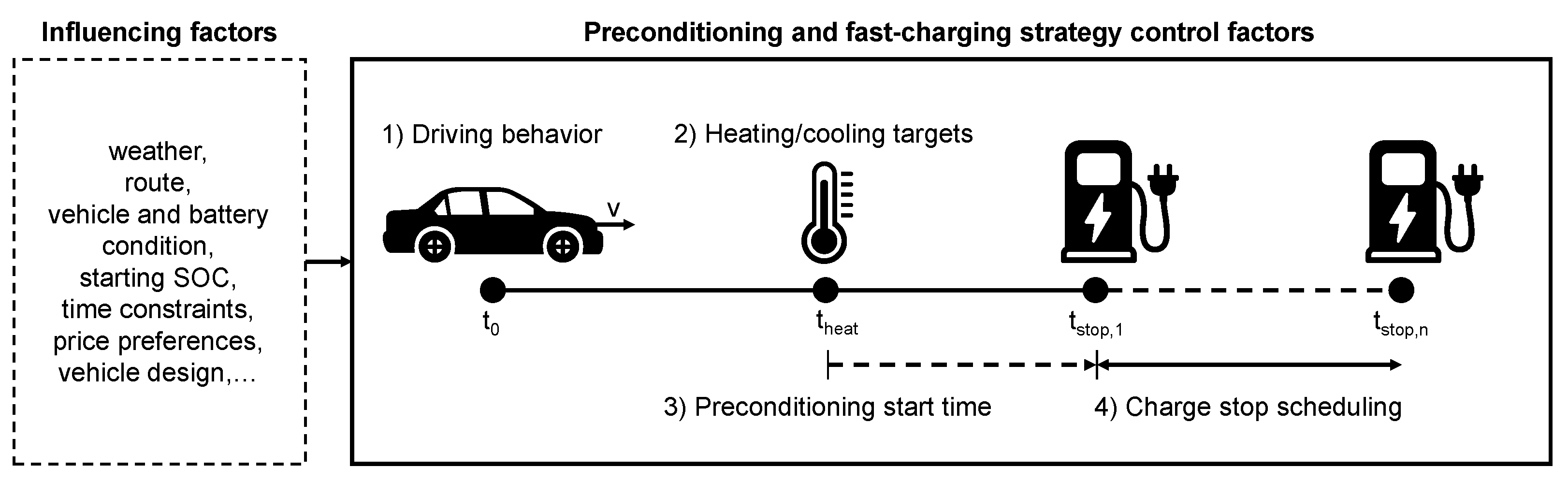

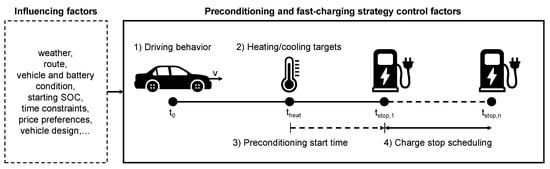

In this study, we examine the influence of different operation parameters on achievable fast-charging times and energy consumption to derive strategy recommendations at the vehicle level. These include the vehicle driving behavior, the temperature targets for battery cooling or heating, the timing of preconditioning prior to a charge stop, and the scheduling of charge stops at different SOCs. These factors are influenced by many environmental and technical conditions, which have to be taken into account for practical applications, as depicted in Figure 1.

Figure 1.

Influencing and control factors for vehicle-level fast-charging and preconditioning strategies using model-based approaches.

Through such multi-scale examinations, physics-informed operation decisions can be made at the vehicle level, facilitating trade-offs between charging time and energy consumption depending on the specific use case and vehicle or ambient conditions.

1.2. Organization of the Article

The remainder of this article is structured as follows: Section 2 presents the utilized methodology consisting of an electrochemical battery model coupled with a longitudinal vehicle model in MATLAB/Simulink®, as well as the used vehicle and battery parameters. Section 3 presents the general impact of different thermal conditions, charge-stop SOCs, heating efficiencies, and driving behavior on the vehicle-level fast-charging capability and energy consumption before analyzing the impact of different operation strategies by the example of a typical long-distance journey. Section 4 concludes with derived operation recommendations for vehicle fast-charging applications and an outlook on limitations and future work.

2. Methodology

To examine the fast-charging behavior under different ambient and battery conditions, as well as preconditioning strategies, a longitudinal vehicle dynamics model is implemented in MATLAB/Simulink® (https://ww2.mathworks.cn/products/simulink.html, accessed on 14 August 2024). The vehicle under study represents a hypothetical mid-size current-generation electric vehicle with an 800 V battery system with a capacity of 65 kWh. Using the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) driving profile, the model calculates the resulting current profiles, which is input into a commercially available electrochemical battery model by the company Batemo [32]. The battery cell under study is a high-power 18650 cell by TerraE with a nominal capacity of Ah. The used vehicle and battery parameters are listed in Table 1. The vehicle longitudinal forces are modeled according to the following equation:

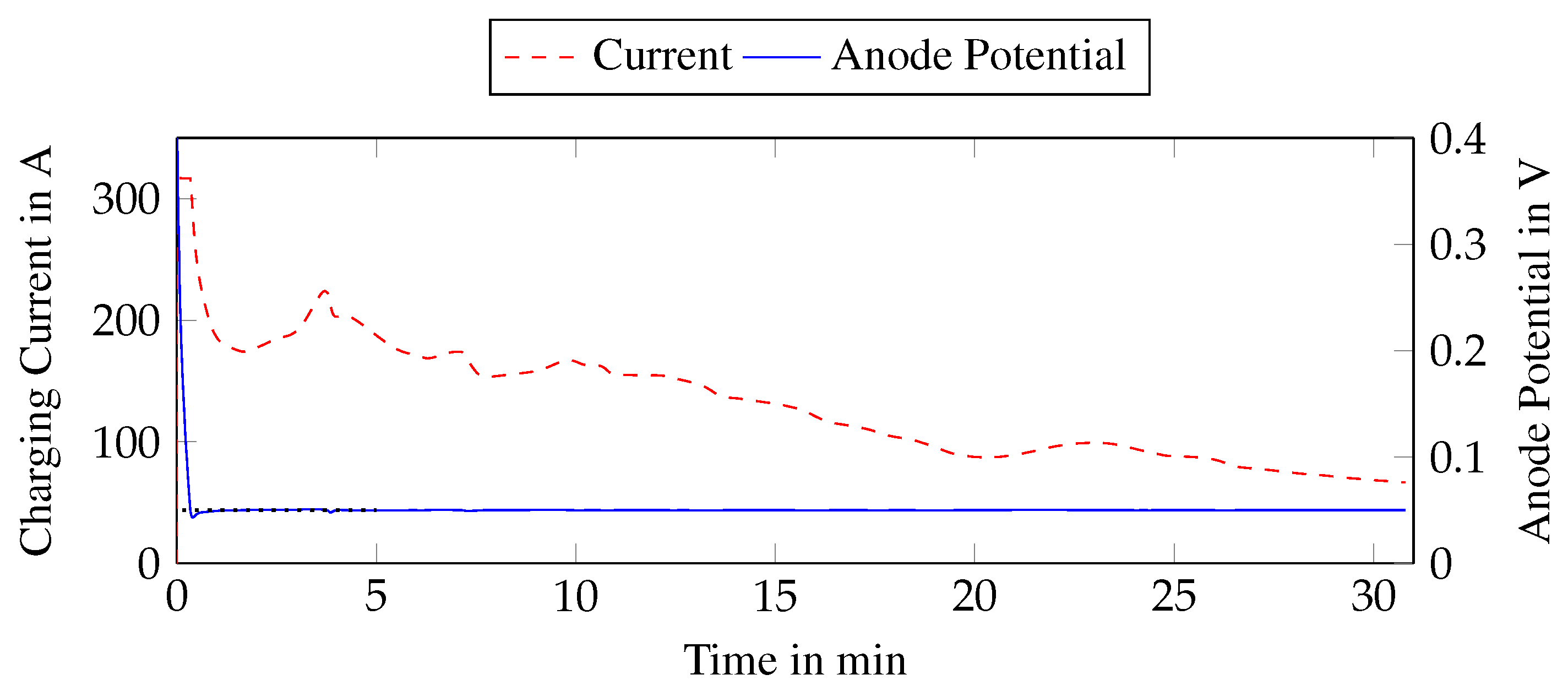

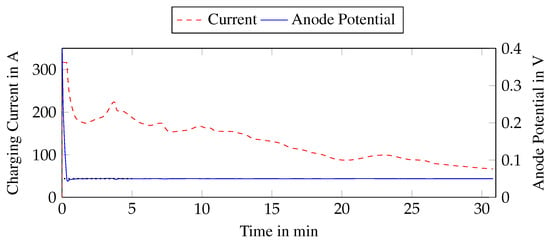

with the air density , the velocity v, the gravitational acceleration g, and the remaining parameters as listed in Table 1. An additional inertia coefficient of is used to account for the acceleration of rotational masses within the vehicle. The vehicle is operated at ambient temperatures of °C to 30 °C. At charging SOCs of 10% or 30%, the vehicle is stopped and charged using an anode potential control strategy with a maximum charge rate of 4C. The current is hereby controlled using a PID controller to maintain an anode potential reserve of 50 mV, which achieves maximum charging speed while preventing the onset of lithium plating [33]. An example charging profile is shown in Figure 2.

Figure 2.

Charging procedure for the battery pack with an initial charging rate of 4C from 0% to 80% SOC at a starting temperature of °C using anode potential control.

Additionally, a thermal management system is modeled, which heats the battery to target temperatures of up to 40 °C before the charging event with an assumed heating power of W per cell and a coefficient of performance (COP) value of 1. This represents a direct translation of electrical power to heating power, such as using a resistive heater while neglecting conductive losses. It should be noted that electric vehicles are equipped with different heating technologies in practice, ranging from drivetrain heat loss usage to dedicated heat pumps, which leads to lower or higher COP values [12,34,35]. Heat losses to ambient are considered using a heat transfer coefficient of 22 W/K, which was determined experimentally from the Tesla Model 3 in a previous study [36]. The battery is furthermore cooled with a power of W per cell with a COP value of 2, which is representative of the commonly used integration of the battery in the refrigerant circuit to maintain a maximum temperature of 60 °C and return the battery to a temperature of 25 °C after the charge is complete. This follows a similar approach as preconditioning strategies observed in state-of-the-art vehicles [9]. These parameters are reference conditions, which are utilized to examine the coupled impact of electrical and thermal behavior during vehicle fast-charging. These form the foundation for further analyses, in which heating thresholds and timings, as well as driving and charge stop behavior, are varied to achieve improved charging times while taking energy cost into account.

Leveraging the demonstrated relationships between ambient and initial conditions, as well as preconditioning strategy and driving behavior, we simulate an example long-distance journey of 400 km with a full battery at different ambient conditions to propose a fast-charging thermal management and vehicle operation strategy that provides a trade-off between charging time and energy consumption. This is achieved by reflecting user preferences through the definition of a maximum energy cost per charge time reduction, allowing preconditioning target temperatures to be selected depending on the importance of charge duration versus cost and preventing battery heating beyond the point of receding benefits. This is expected to additionally reduce other degradation mechanisms that are exacerbated at high temperatures. The resulting operation recommendations could be implemented in electric vehicles in the form of lookup tables, allowing for easy implementation in current hard- and software infrastructures.

Table 1.

Parameters of the modeled electric vehicle and battery.

Table 1.

Parameters of the modeled electric vehicle and battery.

| Domain | Property | Value | Unit |

|---|---|---|---|

| Vehicle | Vehicle mass m | 1870 | kg |

| Drag coefficient | 0.288 | - | |

| Vehicle cross-section A | 2.576 | ||

| Rolling resistance coefficient | 0.015 | - | |

| Battery pack | Capacity | 65 | kWh |

| Nominal voltage | 800 | V | |

| Total cells | 7359 | - | |

| Series cells | 223 | - | |

| Parallel cells | 33 | - | |

| Heat transfer coefficient | 22.2 [36] | W/K | |

| Battery thermal management | Heater COP | 1 | - |

| Heating power per cell | 0.5 | W | |

| Cooler COP | 2 | - | |

| Cooling power per cell | 1.5 | W | |

| Cooling maximum threshold | 60 | °C | |

| Cell | Manufacturer | TerraE | - |

| Type | INR18650-25P | - | |

| Format | 18650 | - | |

| Anode material | Graphite | - | |

| Cathode material | NMC | - | |

| Rated capacity | 2.5 | Ah | |

| Voltage boundaries | 2.5–4.2 | V | |

| Nominal voltage | 3.6 | V | |

| Maximum charge rate | 4 | C |

3. Results and Discussion

The following section examines the impact of different driving and preconditioning behaviors under various operation conditions regarding resulting charge speed and energy consumption. Building upon this, an example journey of 400 km is simulated to propose a thermal management strategy that balances charging speed and efficiency.

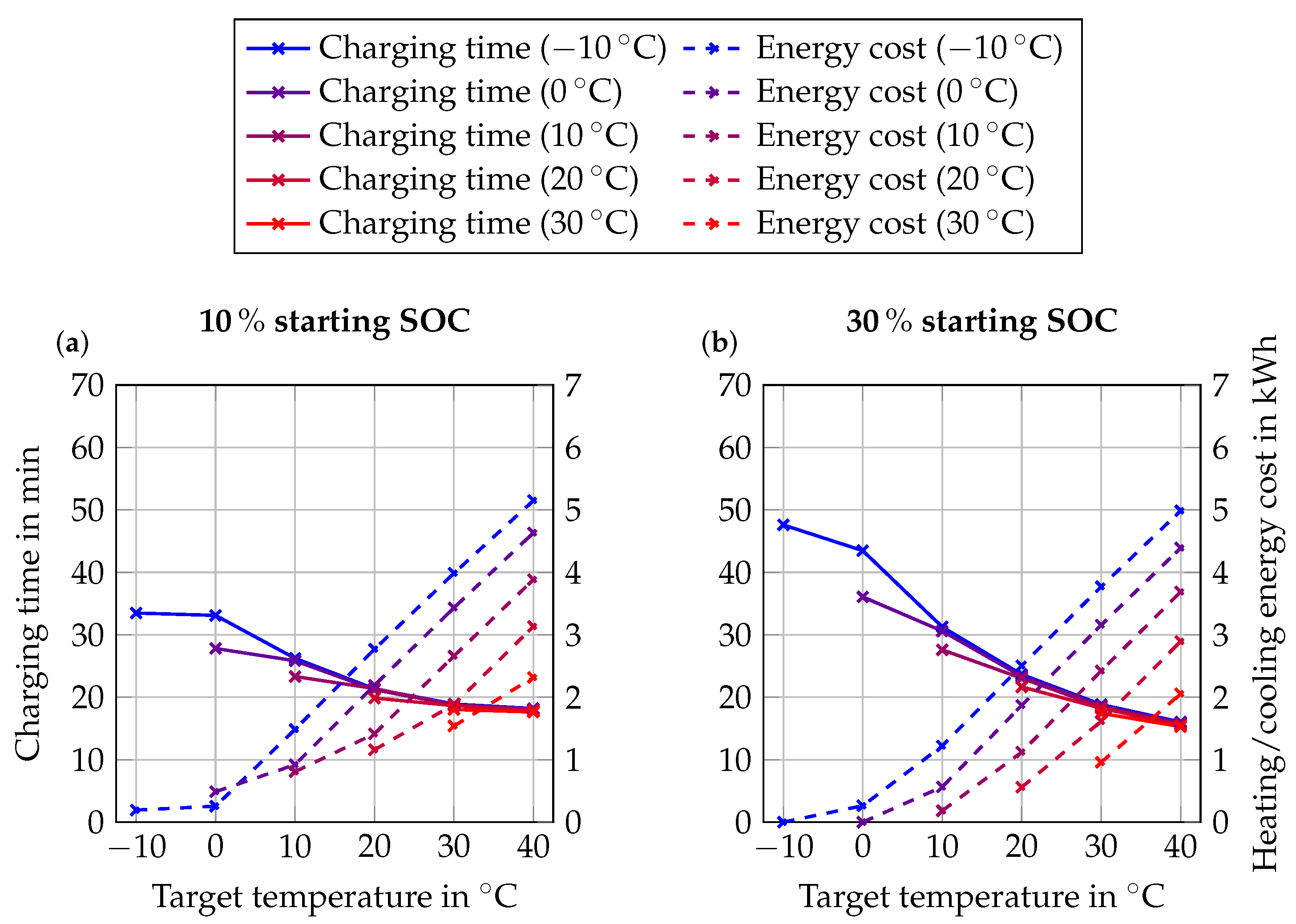

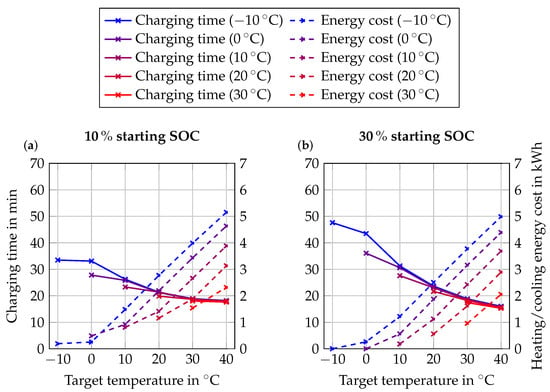

3.1. Impact of Preconditioning on Charge Speed and Energy Consumption

Figure 3 shows the resulting charging times versus combined preheating and cooling energy consumption for both simulated charge stops at different ambient and preconditioning target temperatures, with heating starting 1 h before the charging event. It becomes apparent that higher target temperatures lead to shorter charging times, allowing for a reduction by up to 60%. This is due to the beneficial impact of higher temperatures regarding reduced anode overpotentials, leading to a later derating of the current. Higher temperatures, however, show diminishing benefits, while the associated energy cost to heat the battery and subsequently cool it grows almost linearly. Furthermore, temperature dependency and preheating benefits are more pronounced at higher starting SOCs, as the battery has less time to self-heat while charging, which matches the observations from the literature [6].

Figure 3.

Charging times to 80% SOC and energy consumption at the vehicle level using anode potential control at (a) 10% and (b) 30% charging event starting SOC and ambient temperatures of °C to 30 °C with preconditioning to target temperatures of 0 °C to 40 °C 1 h before the charging event.

On the contrary, lower starting SOCs allow the battery more time to self-heat during the charge, facilitating faster charging times due to higher anode potentials [6]. This is in line with previous examinations at cell level [9], although the effect is less pronounced, as vehicle battery packs show stronger self-heating behavior due to the increased thermal isolation compared to single cells under laboratory conditions.

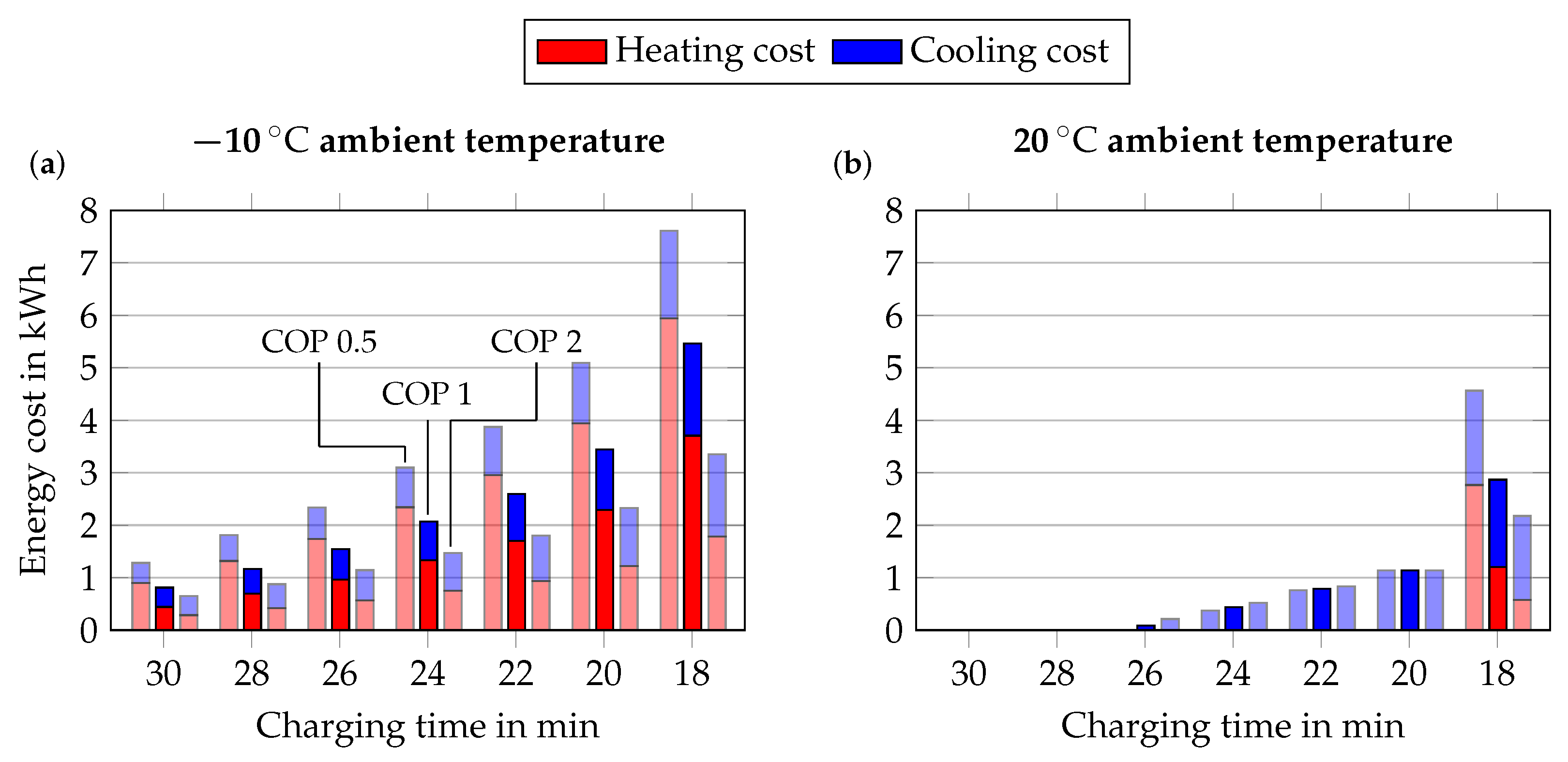

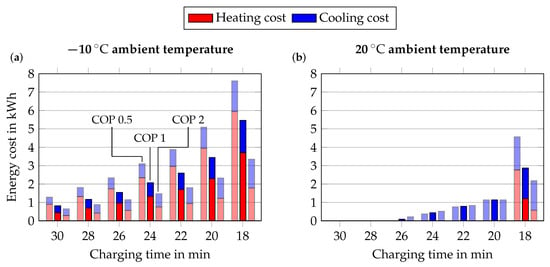

To evaluate the resulting economic impact, Figure 4 shows the associated energy consumptions for heating and cooling the battery to achieve charging times of 30 min to 18 min from 10% to 80% SOC at ambient temperatures of °C and 20 °C using heater COP values of , 1, and 2. This shows exponentially growing thermal management energy costs, leading to an additional consumption of up to kWh with the chosen default heater to achieve a charging time of 18 min, which corresponds to more than 10% of the total charged energy. For increasing ambient temperatures, this effect is not only driven by heating costs but also increasing cooling requirements to maintain recommended battery temperatures during and after the fast charge event.

Figure 4.

Energy cost for battery heating and cooling required to achieve different charging times from 10% to 80% SOC at ambient temperatures of (a) °C and (b) 20 °C. Results are shown for battery heater COP values of 0.5, 1, and 2.

These findings emphasize the need for model-based fast-charging strategies to take vehicle-level integration into account to achieve the optimal trade-off between charge time reduction and energy cost depending on the respective vehicle concept and driving behavior. This is expected to differ depending on the utilized cell, as designs vary strongly depending on the specific trade-off between power and energy requirements [37], especially in regard to temperature rise [38] and heat rejection [39], which has been shown to strongly influence fast-charging performance [40]. Furthermore, this consumption represents hidden costs that are not directly apparent to the vehicle owner, as they are not directly visible in the charging process. This neglects potential differences regarding fast-charging preferences, for example, when the driver explicitly desires longer breaks.

The energy cost of battery preconditioning is expected to strongly influence the resulting optimal thermal management and fast-charging strategy and is directly linked to the efficiency of the installed battery heater [12,34,35]. These can range from indirect methods, such as the so-called ’waste heat mode’ in the Tesla Model 3, in which additional losses in the electric motor are generated and fed into the battery [36], to dedicated heaters, for example, using heat pumps, which are more efficient than resistance heaters as they utilize heat from ambient or other powertrain components.

To evaluate the impact of the installed thermal management system, we repeat the previous examination at °C for heater COP values of 0.5 and 2 instead of the initial value of 1, representing, respectively, a more inefficient and more efficient implementation. The resulting thermal management energy consumption for different charging speeds is also shown in Figure 4. With the less-efficient thermal management system, heating dominates the required energy to achieve higher charging speeds, leading to additional consumptions of up to kWh per charge at °C ambient. Even at 20 °C ambient temperature, achieving 18 min charging time costs over 4 kWh in additional thermal management energy, almost 3 kWh of which in heating energy, which lies in the same magnitude as the measured heating energy consumption in the Tesla Model 3 [36].

These results emphasize the importance of equipping next-generation electric vehicles with dedicated and efficient battery heaters, facilitating high charging speeds with reduced additional energy costs. For example, heat pump functionality could also be used for battery heating, which would increase costs and complexity but may offer long-term benefits regarding charging performance, especially in colder regions. Novel preconditioning technologies such as internal heating are increasingly being investigated, which may offer further benefits compared to current approaches [34]. Depending on the resulting energy balances, we expect different thermal management strategies to become more attractive, necessitating the fast-charging behavior to be considered during the thermal management design phase and vice versa. For the remainder of this study, we assume a heater COP value of 1.

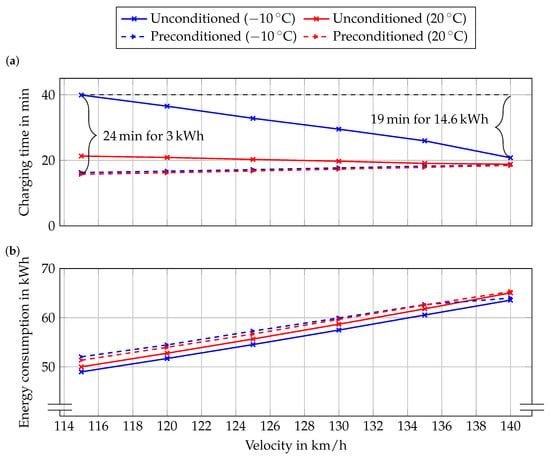

3.2. Impact of Vehicle Velocity on Charge Speed and Energy Consumption

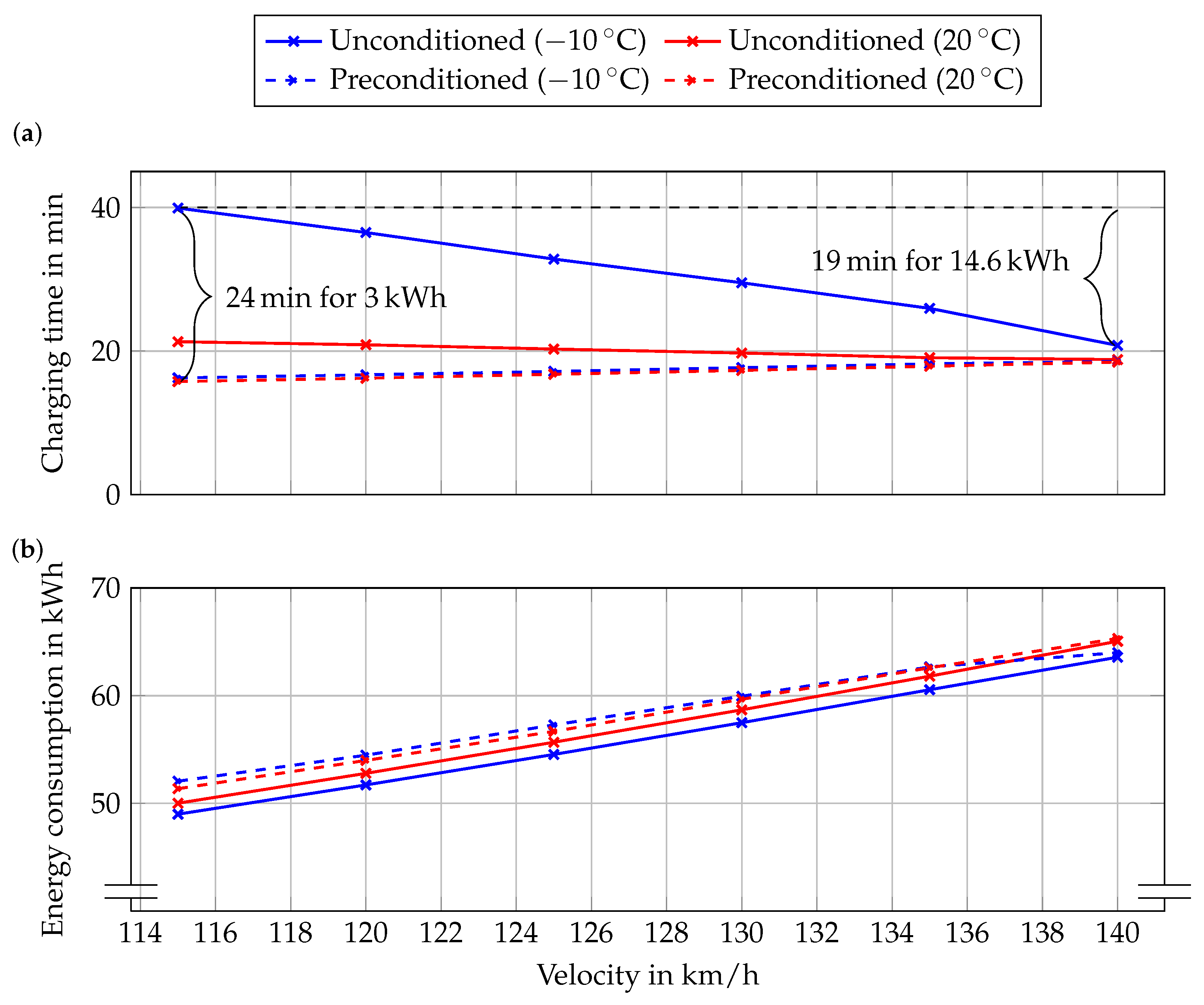

Having established the beneficial impact of low initial SOCs and high battery temperatures for fast-charging time, the impact of driving behavior can be evaluated. For this purpose, we simulate driving at a constant velocity between 115 km/h and 140 km/h at °C and 20 °C for an initially full battery without preconditioning and a battery that is heated to 40 °C just in time for the charge stop. The distance before the charge stop is defined in reference to a 30% stop SOC at 115 km/h to examine the impact of faster driving speeds without changing the vehicle route. The resulting charging times to 80% SOC, as well as the total energy consumption for driving, thermal management, and charging, are shown in Figure 5.

Figure 5.

(a) Charging time and (b) total energy consumption for charge stops to 80% SOC with an unconditioned and 40 °C preconditioned battery at ambient temperatures of °C and 20 °C. Charge stops are performed at the same travel distance with different vehicle velocities.

Under cold ambient conditions, higher vehicle velocities result in faster charging times despite charging more energy. This is due to the lower charge-stop SOC caused by the higher energy consumption, as well as the higher battery temperature due to increased losses. This, however, coincides with significantly increased energy costs, which grow with the cube of the velocity due to air resistance. At warmer ambient conditions, higher velocities offer almost no benefit for charging speed. When preconditioning to 40 °C is possible, the charging time becomes almost independent of the vehicle velocity, achieving greater time savings for only 20% of the energy cost of driving faster in the worst-case scenario. In this case, higher velocities slightly increase the charge duration, as more energy has to be charged without the added benefit of higher temperatures.

We thus conclude that if the vehicle is operated at high velocities, battery preconditioning becomes increasingly redundant. For this reason, the driving behavior has to be considered in the thermal management and fast-charging strategy to prevent unnecessary preconditioning costs, which could be taken into account through joint optimization [41]. Inversely, in the case of cold ambient conditions and constraints that prevent low-SOC charge stops, such as limited infrastructure, higher velocities can shorten the charge stop by up to 50%. This may also be the case for spontaneous charge stops without sufficient prior time for preconditioning. However, active heating achieves greater charge time benefits for significantly less energy than increasing the vehicle velocity. In this case, changes to the driving behavior are only relevant depending on the travel time versus energy cost preferences of the driver.

3.3. Proposed Thermal Management Strategy

By coupling electrochemical battery models that provide physics-based charging profiles and vehicle modeling, it becomes possible to design vehicle-level fast-charging strategies. To demonstrate this, we simulate an example long-distance journey of 400 km, which is approximately the distance for a typical holiday journey between the cities of Munich and Verona. To reflect realistic user behavior, we assume a departure in Munich with a full battery, a constant velocity of 120 km/h, and a single fast-charging stop en route with a targeted arrival SOC of 20% in Verona. Building upon this, we examine the impact of charge stop timing, preconditioning start time, and target temperature to derive recommendations for vehicle-level fast-charging strategies.

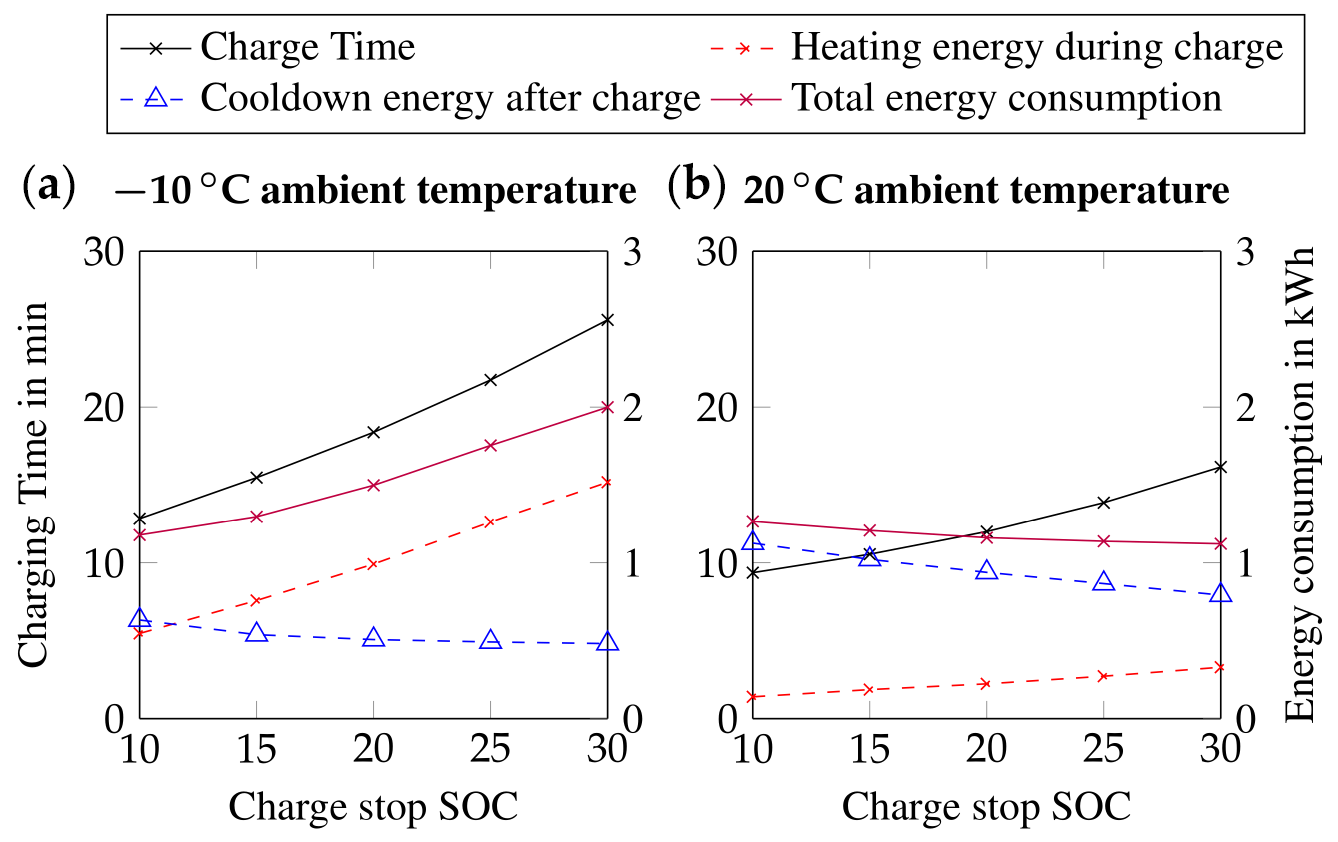

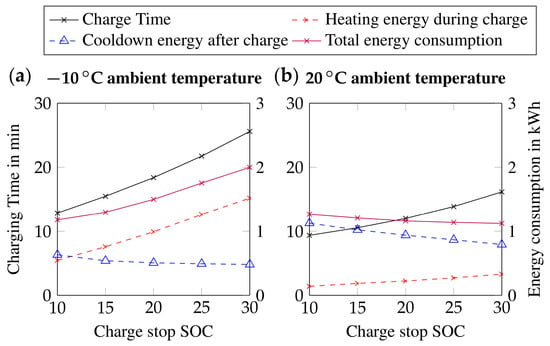

3.3.1. Timing of Charge Stop and Preconditioning

As previously shown, the achievable charging time depends strongly on the initial temperature and SOC of the battery. Given a predefined ambient temperature, the first step in deriving an optimized fast-charging strategy is the selection of the charge stop timing, e.g., the starting SOC of the charge process. Building upon the previously shown increase in charge speed at lower starting SOC, we examine the impact on charge duration and thermal management energy consumption for the defined example route. To decouple the effect of preconditioning, we only assume battery heating to a target temperature of 40 °C at the charge station during the charging process, as observed in the Tesla Model 3 when no preconditioning is performed [36]. The results of this can be seen in Figure 6. With both ambient temperatures, the previously observed sensitivity to the starting SOC leads to a doubling of the charge duration for 30% instead of 10% starting SOC, despite approximately charging the same amount of energy of 20 kWh. This is due to two effects, namely a shift of the charge stop target SOC towards higher regions, increasing the risk of lithium plating, and less potential for self-heating as the current needs to be reduced earlier in the charging process. The latter effect results in more energy being required to heat the battery parallel to the charging process, which results in longer charge durations and an almost twofold increase in energy consumption for lower temperatures. It can thus be concluded that the most significant increase in charge speed for a given route can be achieved by charging at the lowest possible SOC. This has to be weighed against available infrastructure considerations and range anxiety, which leads many vehicle owners to charge at higher SOCs [31]. This conflict has been extensively addressed in past research in the context of the vehicle routing problem [42]. For future research, we propose extending existing charge stop optimization approaches for multiple charge events with nonlinear charging profiles derived from anode potential control with electrochemical battery models, allowing physics-motivated routing decisions to minimize charge and total travel duration based on the existing infrastructure.

Figure 6.

Charging time and thermal management energy consumption for different charge-stop SOCs at (a) °C and (b) 20 °C ambient temperature with no preconditioning and with heating during charge to a target temperature of 40 °C. During each charge process, approximately 20 kWh of energy is charged.

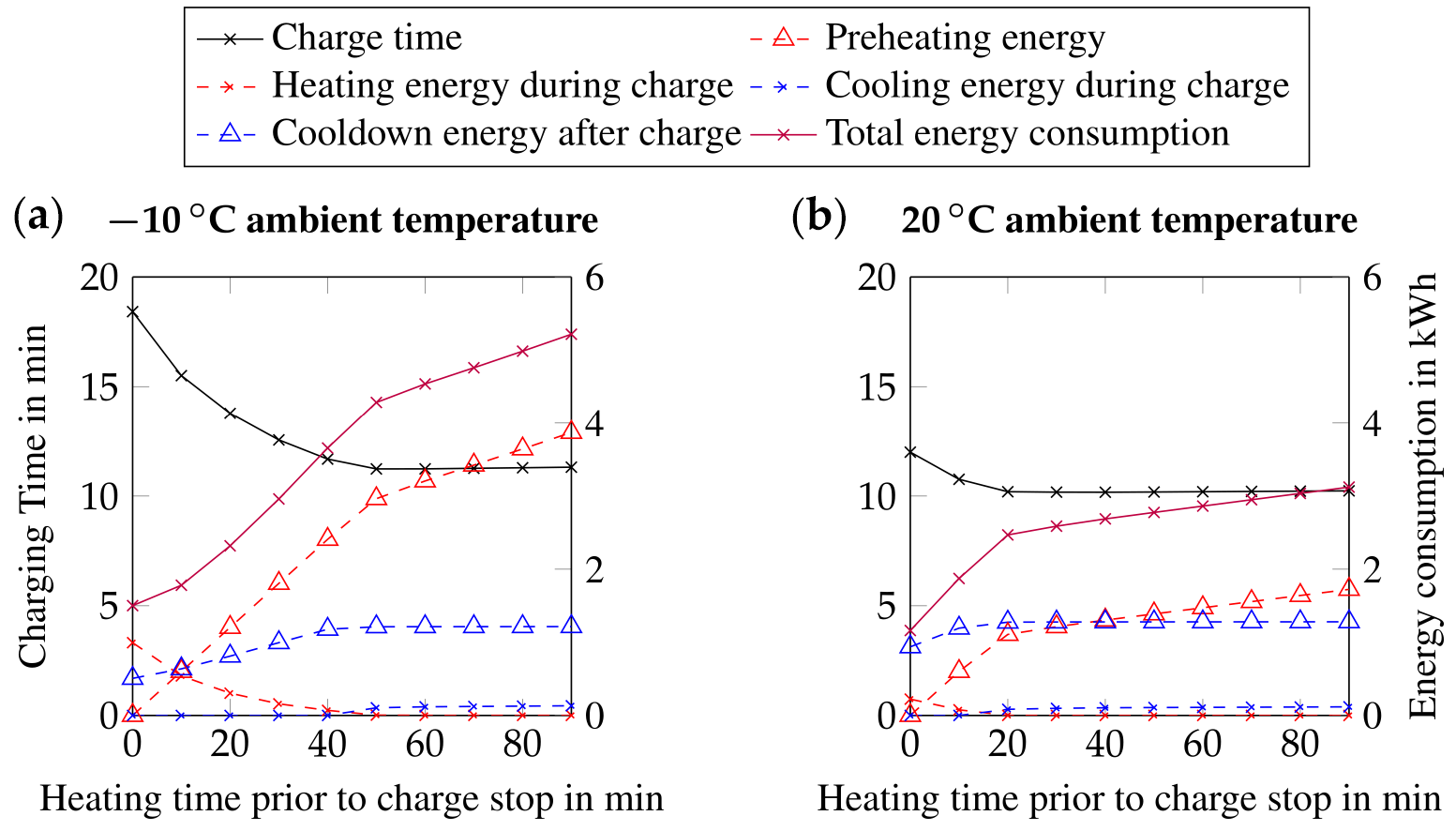

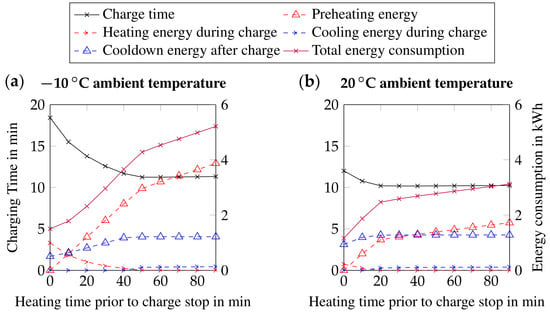

After determining the charge stop location and SOC, the next option in thermal management strategy lies in the derivation of the preconditioning approach. For a given ambient temperature and preconditioning target temperature, optimization potential may be found in the timing of the preconditioning process. State-of-the-art electric vehicles such as the Tesla Model 3 have been observed to start heating the battery up to 1 h before the scheduled charge stop [9]. While earlier heating allows sufficient time for the battery to reach the desired temperature, it may also risk excessive energy consumption to maintain the temperature, as well as accelerated battery degradation due to longer periods at elevated temperatures [1]. To examine the trade-off between charging time and energy consumption, we simulate a charge stop at 20% of SOC for the example route at ambient temperatures of °C and 20 °C. The battery is hereby heated to 40 °C up to 90 min before the charge stop, the results of which can be seen in Figure 7. As more time is allowed for preconditioning, charge times decrease due to the battery reaching higher temperatures at the start of the charging process. This is accompanied by almost linearly increasing energy costs for heating en route and cooling after the charge is complete, as well as decreasing energy required to heat during the charging process. Once the preconditioning time is sufficient for the target temperature to be reached before the charge stop, no further benefits in charging time can be achieved, whereas the energy costs increase due to the energy required to maintain battery temperature. Using a preconditioning timing of 1 h would thus achieve maximum charging speed with acceptable energy consumption for the battery under study. Energy savings of up to 1 kWh could, however, be achieved by adjusting the heating time to the ambient temperature without compromising charge speed, such as heating 45 min in advance at °C and 20 min in advance at 20 °C. We, however, note that further consideration must take deviations into account due to driving behavior, traffic conditions, or other uncertainties, such as the battery heat transfer coefficient, which supports increasing the preconditioning time to maintain a safety margin. The latter is especially expected to have a large impact on the optimal thermal management strategy, as a thermally more isolated battery pack requires less heating but more cooling. Furthermore, longer preconditioning times may be required to achieve temperature homogeneity within the battery pack, which is required to minimize the adverse effects of temperature gradients during fast-charging [43].

Figure 7.

Charging time and thermal management energy consumption for different preheating start times prior to a charge stop at (a) °C and (b) 20 °C ambient temperature and a charge stop at 20% SOC with preconditioning and heating during charge to a target temperature of 40 °C.

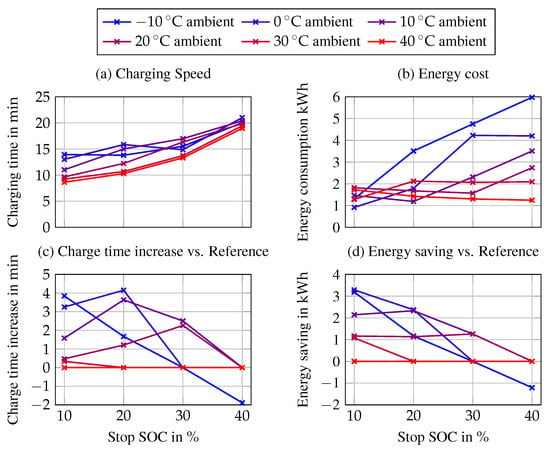

3.3.2. Preconditioning Target Temperature

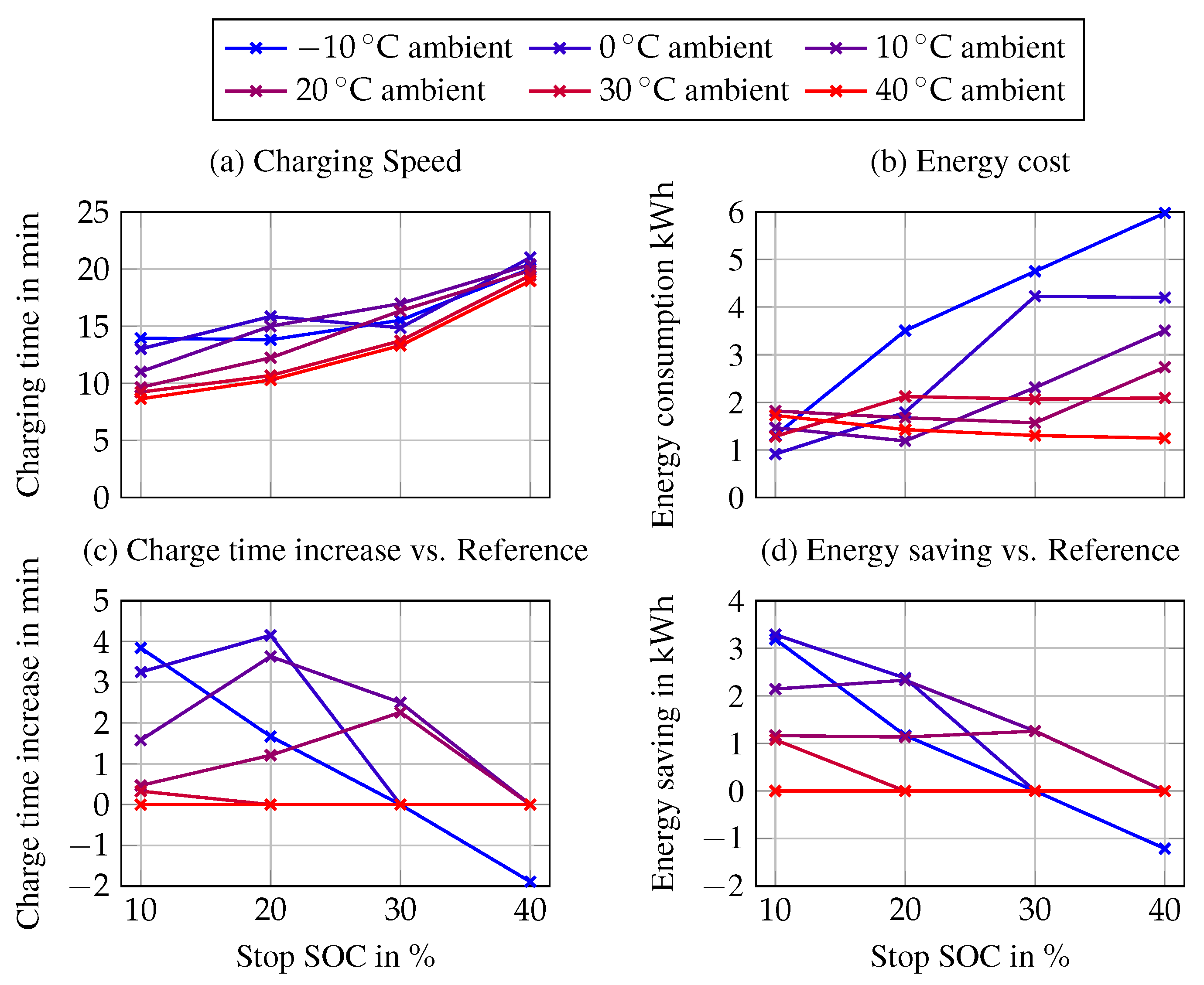

The final step in determining fast-charging preconditioning strategies lies in the temperature thresholds. As the cooling threshold is a safety factor that is usually defined in the battery datasheet, we assume a valid maximum temperature of 60 °C and instead focus on the heating target temperature. As previously shown, higher heating target temperatures increase charging speed; however, this comes at the cost of growing energy consumption and aging. This leads to receding benefits of battery heating, causing charge speed costs to grow exponentially. While performance-oriented users may elect to heat to the highest target temperatures, allowing for the fastest charging experience, a more economical approach may be found in trading off the charge time reduction with the increase in energy consumption. This could be achieved by defining a minimum acceptable charge time reduction per additional of thermal management energy required. To demonstrate this, we define the value as a 3 min minimum speed increase per additional consumed for preconditioning. However, the concrete value can be defined based on user preference. By performing an extensive simulation study, heating thresholds that balance both energy consumption and charging speed can be selected. These can be seen in Table 2, assuming heating 1 h before the charge stop. For lower charge-stop SOCs, the inherent self-heating of the battery during charging can be leveraged, requiring less external heating and thus less energy. The resulting charge speeds and energy consumptions can be seen in Figure 8a,b, as compared to a reference strategy of always heating to 40 °C in Figure 8c,d. Using the cost-aware charging strategy, charging times of below 20 min can be achieved for almost all examined starting conditions, with both charging duration and additional energy consumption increasing for higher start SOCs. By limiting the preconditioning target temperatures using the proposed cost factor, fast-charging can be maintained with increases of only up to 4 min in the low-SOC region compared to the reference, still allowing a total charge stop duration below 15 min to charge the required energy. At the same time, this can lead to energy savings of more than 3 kWh. This may pose a more attractive approach to deriving thermal management strategies in cost-critical use cases, such as commercial vehicles with frequent fast-charging requirements, or allow vehicle users to prioritize based on personal preferences.

Table 2.

Cost-adjusted preconditioning thresholds.

Figure 8.

(a) Charging time and (b) energy consumption for the cost-aware preconditioning strategy, as well as (c) charge time increase and (d) energy saving for the proposed strategy compared to a reference thermal management strategy during which the battery is always heated to 40 °C. The results are shown for ambient temperatures of °C to 40 °C, as well as charge-stop SOCs of 10% to 40%.

4. Conclusions

By utilizing electrochemical battery models, physics-based fast-charging strategies can be derived that allow maximum charging speed while mitigating the risk of adverse side reactions such as lithium plating. Through coupling the derived information with vehicle-level considerations and ambient conditions, we demonstrate the impact of different thermal management and routing decisions on the achievable charging speeds and energy consumption, which can be summarized as follows:

- Fast-charging should be performed at the lowest possible charge-stop SOC to prevent the increased risk of lithium plating at higher SOCs and allow for maximum self-heating during the charging process, reducing the need for external heating and thus saving energy. This is especially critical at low ambient temperatures.

- Preconditioning target temperatures should be chosen based on user preferences regarding energy cost vs. charging speed, preventing excessive energy consumption for receding charge speed benefits by leveraging the inherent self-heating during the charging process. For the battery under study, this can facilitate energy savings of over 3 kWh while only slightly impacting charging speed, which may be attractive in cost-critical use cases.

- The preconditioning process should be initialized sufficiently early to achieve the desired temperature while minimizing the time maintained at elevated temperatures to reduce energy cost and degradation while maintaining identical charging speeds. However, an additional buffer should be considered to consider uncertainties and allow for homogeneous battery heating. A preconditioning time window of 1 h appears to offer a compromise between achieving maximum charging speed without excessive energy consumption. Further examinations are required to propose optimized preconditioning timing depending on battery pack effects and ambient conditions.

- When the vehicle is operated at higher velocities, preconditioning offers diminishing charge time benefits. Vehicle manufacturers should thus take driving behavior into account when designing fast-charging strategies. For vehicles operated without active battery heating at low ambient conditions, increasing the velocity may allow for higher charging speeds but significantly increases energy costs. When active battery heating is available, higher vehicle velocities offer no benefit towards charge duration.

- Charging speed and energy efficiency can be significantly increased by installing dedicated battery heaters, such as utilizing the vehicle heat pump. This has to be weighed against potential increases in weight, complexity, and cost, posing a design trade-off for vehicle manufacturers to consider depending on the concrete use case.

Future research will extend the proposed concept by examining the impact of different battery types, vehicle concepts, and mobility behaviors. Furthermore, the impact of battery degradation has to be considered, as well as the interplay between thermal management strategy and resulting thermal gradients within the battery pack. Finally, the proposed methodology can be embedded in vehicle routing algorithms to provide a methodology for integrating physics-based charging strategies in vehicle use cases, allowing for the derivation of optimal charge stop and operation strategies for any desired use case.

Author Contributions

Conceptualization, K.A.G.; methodology, K.A.G., M.Z. and A.L.; software, K.A.G. and A.L.; formal analysis, K.A.G.; investigation, K.A.G.; data curation, K.A.G.; writing—original draft preparation, K.A.G., M.Z. and C.A.; writing—review and editing, K.A.G., M.Z., C.A. and M.L.; visualization, K.A.G.; supervision, M.L.; project administration, K.A.G.; funding acquisition, M.L. All authors have read and agreed to the published version of the manuscript.

Funding

The authors greatly acknowledge the funding provided by the German Federal Ministry for Economic Affairs and Climate Action (BMWK) within the projects “ultraBatt” under grant number 01MV21015D and “NEFTON” under grant number 01MV21004A.

Data Availability Statement

The raw data supporting the conclusions of this article can be viewed under the following link: https://doi.org/10.14459/2024mp1750774.

Acknowledgments

We thank Batemo for providing the cell model for the TerraE INR18650-25P. We would also like to thank Johannes Huber and Christian Huber for their support during their master’s studies.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| BEV | battery electric vehicle |

| COP | coefficient of performance |

| SOC | state-of-charge |

| WLTP | Worldwide Harmonized Light Vehicles Test Procedure |

References

- Dufek, E.J.; Abraham, D.P.; Bloom, I.; Chen, B.R.; Chinnam, P.R.; Colclasure, A.M.; Gering, K.L.; Keyser, M.; Kim, S.; Mai, W.; et al. Developing extreme fast charge battery protocols—A review spanning materials to systems. J. Power Sources 2022, 526, 231129. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Thapa, A.; Hedding, N.; Gao, H. Fast charging of commercial lithium-ion battery without lithium plating. J. Energy Storage 2023, 74, 109524. [Google Scholar] [CrossRef]

- Liu, C.; Gao, Y.; Liu, L. Toward safe and rapid battery charging: Design optimal fast charging strategies thorough a physics–based model considering lithium plating. Int. J. Energy Res. 2021, 45, 2303–2320. [Google Scholar] [CrossRef]

- Yang, S.; Gao, X.; Li, Y.; Xie, W.; Guo, B.; Zhang, L.; Liu, X. Minimum lithium plating overpotential control based charging strategy for parallel battery module prevents side reactions. J. Power Sources 2021, 494, 229772. [Google Scholar] [CrossRef]

- Pegel, H.; Wycisk, D.; Scheible, A.; Tendera, L.; Latz, A.; Sauer, D.U. Fast-charging performance and optimal thermal management of large-format full-tab cylindrical lithium-ion cells under varying environmental conditions. J. Power Sources 2023, 556, 232408. [Google Scholar] [CrossRef]

- Motoaki, Y.; Yi, W.; Salisbury, S. Empirical analysis of electric vehicle fast charging under cold temperatures. Energy Policy 2018, 122, 162–168. [Google Scholar] [CrossRef]

- Liu, T.; Ge, S.; Yang, X.G.; Wang, C.Y. Effect of thermal environments on fast charging Li-ion batteries. J. Power Sources 2021, 511, 230466. [Google Scholar] [CrossRef]

- Abo Gamra, K.; Wassiliadis, N.; Allgäuer, C.; Lienkamp, M. Revealing the effect of initial conditions and the potential of self-heating versus active heating on fast-charged lithium-ion batteries. J. Energy Storage 2024, 84, 110968. [Google Scholar] [CrossRef]

- Yang, X.G.; Wang, C.Y. Understanding the trilemma of fast charging, energy density and cycle life of lithium-ion batteries. J. Power Sources 2018, 402, 489–498. [Google Scholar] [CrossRef]

- Abo Gamra, K.; Zähringer, M.; Allgäuer, C.; Lienkamp, M. Examining Model-Based Fast-Charging on Vehicle-Level. In Proceedings of the EVS37 International Electric Vehicle Symposium and Exhibition, Seoul, Republic of Korea, 23–26 April 20204. [Google Scholar]

- Hu, X.; Zheng, Y.; Howey, D.A.; Perez, H.; Foley, A.; Pecht, M. Battery warm-up methodologies at subzero temperatures for automotive applications: Recent advances and perspectives. Prog. Energy Combust. Sci. 2020, 77, 100806. [Google Scholar] [CrossRef]

- Burnham, A.; Dufek, E.J.; Stephens, T.; Francfort, J.; Michelbacher, C.; Carlson, R.B.; Zhang, J.; Vijayagopal, R.; Dias, F.; Mohanpurkar, M.; et al. Enabling fast charging—Infrastructure and economic considerations. J. Power Sources 2017, 367, 237–249. [Google Scholar] [CrossRef]

- Keyser, M.; Pesaran, A.; Li, Q.; Santhanagopalan, S.; Smith, K.; Wood, E.; Ahmed, S.; Bloom, I.; Dufek, E.; Shirk, M.; et al. Enabling fast charging—Battery thermal considerations. J. Power Sources 2017, 367, 228–236. [Google Scholar] [CrossRef]

- Meintz, A.; Zhang, J.; Vijayagopal, R.; Kreutzer, C.; Ahmed, S.; Bloom, I.; Burnham, A.; Carlson, R.B.; Dias, F.; Dufek, E.J.; et al. Enabling fast charging—Vehicle considerations. J. Power Sources 2017, 367, 216–227. [Google Scholar] [CrossRef]

- Yin, Y.; Hu, Y.; Choe, S.Y.; Cho, H.; Joe, W.T. New fast charging method of lithium-ion batteries based on a reduced order electrochemical model considering side reaction. J. Power Sources 2019, 423, 367–379. [Google Scholar] [CrossRef]

- Yin, Y.; Choe, S.Y. Actively temperature controlled health-aware fast charging method for lithium-ion battery using nonlinear model predictive control. Appl. Energy 2020, 271, 115232. [Google Scholar] [CrossRef]

- Wang, Y.; Mao, S.; Chen, Q.; Chen, F.; Zhang, X.; Ouyang, M.; Han, X.; Zheng, Y. Online Fast Charging Model without Lithium Plating for Long-Dimensional Cells in Automotive Applications. Batteries 2023, 9, 563. [Google Scholar] [CrossRef]

- Hamednia, A.; Murgovski, N.; Fredriksson, J.; Forsman, J.; Pourabdollah, M.; Larsson, V. Optimal Thermal Management, Charging, and Eco-Driving of Battery Electric Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 7265–7278. [Google Scholar] [CrossRef]

- Hamednia, A.; Hanson, V.; Zhao, J.; Murgovski, N.; Forsman, J.; Pourabdollah, M.; Larsson, V.; Fredriksson, J. Charge Planning and Thermal Management of Battery Electric Vehicles. IEEE Trans. Veh. Technol. 2023, 72, 14141–14154. [Google Scholar] [CrossRef]

- Zhu, T.; Min, H.; Yu, Y.; Zhao, Z.; Xu, T.; Chen, Y.; Li, X.; Zhang, C. An Optimized Energy Management Strategy for Preheating Vehicle-Mounted Li-ion Batteries at Subzero Temperatures. Energies 2017, 10, 243. [Google Scholar] [CrossRef]

- Zhang, Z.; Min, H.; Yu, Y.; Cao, Q.; Li, M.; Yan, K. An optimal thermal management system heating control strategy for electric vehicles under low-temperature fast charging conditions. Appl. Therm. Eng. 2022, 207, 118123. [Google Scholar] [CrossRef]

- Abbasi, M.H.; Arjmandzadeh, Z.; Zhang, J.; Xu, B.; Krovi, V. Deep reinforcement learning based fast charging and thermal management optimization of an electric vehicle battery pack. J. Energy Storage 2024, 95, 112466. [Google Scholar] [CrossRef]

- Acker, L.; Trunner, E.; Hofmann, P. Optimal Battery Thermal Management During and Prior to Fast Charging using Dynamic Programming. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 19–21 June 2024; pp. 1–8. [Google Scholar] [CrossRef]

- Hu, Q.; Amini, M.R.; Wiese, A.; Seeds, J.B.; Kolmanovsky, I.; Sun, J. Electric Vehicle Enhanced Fast Charging Enabled by Battery Thermal Management and Model Predictive Control. IFAC-Pap. 2023, 56, 10684–10689. [Google Scholar] [CrossRef]

- Hu, Q.; Amini, M.R.; Wiese, A.; Kolmanovsky, I.; Sun, J. Robust Model Predictive Control for Enhanced Fast Charging on Electric Vehicles through Integrated Power and Thermal Management. In Proceedings of the 2023 62nd IEEE Conference on Decision and Control (CDC), Singapore, 13–15 December 2023; pp. 5267–5272. [Google Scholar] [CrossRef]

- Kumar Thakur, A.; Sathyamurthy, R.; Velraj, R.; Saidur, R.; Pandey, A.K.; Ma, Z.; Singh, P.; Hazra, S.K.; Wafa Sharshir, S.; Prabakaran, R.; et al. A state-of-the art review on advancing battery thermal management systems for fast-charging. Appl. Therm. Eng. 2023, 226, 120303. [Google Scholar] [CrossRef]

- Hu, L.; Dong, J.; Lin, Z. Modeling charging behavior of battery electric vehicle drivers: A cumulative prospect theory based approach. Transp. Res. Part C Emerg. Technol. 2019, 102, 474–489. [Google Scholar] [CrossRef]

- Franke, T.; Krems, J.F. Understanding charging behaviour of electric vehicle users. Transp. Res. Part F Traffic Psychol. Behav. 2013, 21, 75–89. [Google Scholar] [CrossRef]

- Zhang, B.; Niu, N.; Li, H.; Wang, Z.; He, W. Could fast battery charging effectively mitigate range anxiety in electric vehicle usage?Evidence from large-scale data on travel and charging in Beijing. Transp. Res. Part D Transp. Environ. 2021, 95, 102840. [Google Scholar] [CrossRef]

- Yang, Y.; Tan, Z.; Ren, Y. Research on Factors That Influence the Fast Charging Behavior of Private Battery Electric Vehicles. Sustainability 2020, 12, 3439. [Google Scholar] [CrossRef]

- Batemo GmbH. TerraE INR18650-25P. Available online: https://www.batemo.com/products/batemo-cell-explorer/terrae-inr18650-25p/#get-report-popup (accessed on 18 July 2024).

- Wassiliadis, N.; Kriegler, J.; Abo Gamra, K.; Lienkamp, M. Model-based health-aware fast charging to mitigate the risk of lithium plating and prolong the cycle life of lithium-ion batteries in electric vehicles. J. Power Sources 2023, 561, 232586. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Chen, Z. Low temperature preheating techniques for Lithium-ion batteries: Recent advances and future challenges. Appl. Energy 2022, 313, 118832. [Google Scholar] [CrossRef]

- Wang, Z.; Du, C. A comprehensive review on thermal management systems for power lithium-ion batteries. Renew. Sustain. Energy Rev. 2021, 139, 110685. [Google Scholar] [CrossRef]

- Rosenberger, N.; Rosner, P.; Bilfinger, P.; Schöberl, J.; Teichert, O.; Schneider, J.; Abo Gamra, K.; Allgäuer, C.; Dietermann, B.; Schreiber, M.; et al. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level. World Electr. Veh. J. 2024, 15, 268. [Google Scholar] [CrossRef]

- Lain, M.J.; Brandon, J.; Kendrick, E. Design Strategies for High Power vs. High Energy Lithium Ion Cells. Batteries 2019, 5, 64. [Google Scholar] [CrossRef]

- Buidin, T.I.C.; Mariasiu, F. Parametric Evaluation of Thermal Behavior for Different Li-Ion Battery Chemistries. Batteries 2022, 8, 291. [Google Scholar] [CrossRef]

- Hales, A.; Diaz, L.B.; Marzook, M.W.; Zhao, Y.; Patel, Y.; Offer, G. The Cell Cooling Coefficient: A Standard to Define Heat Rejection from Lithium-Ion Batteries. J. Electrochem. Soc. 2019, 166, A2383–A2395. [Google Scholar] [CrossRef]

- Pegel, H.; Wycisk, D.; Sauer, D.U. Influence of cell dimensions and housing material on the energy density and fast-charging performance of tabless cylindrical lithium-ion cells. Energy Storage Mater. 2023, 60, 102796. [Google Scholar] [CrossRef]

- Cussigh, M.; Hamacher, T. Optimal Charging and Driving Strategies for Battery Electric Vehicles on Long Distance Trips: A Dynamic Programming Approach; IEEE: Piscataway, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Kucukoglu, I.; Dewil, R.; Cattrysse, D. The electric vehicle routing problem and its variations: A literature review. Comput. Ind. Eng. 2021, 161, 107650. [Google Scholar] [CrossRef]

- Liu, X.; Ai, W.; Naylor Marlow, M.; Patel, Y.; Wu, B. The effect of cell-to-cell variations and thermal gradients on the performance and degradation of lithium-ion battery packs. Appl. Energy 2019, 248, 489–499. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).