An Organizational Model of a Food Production Chain: A Case Study in the Poultry Sector in Foggia (Italy)

Abstract

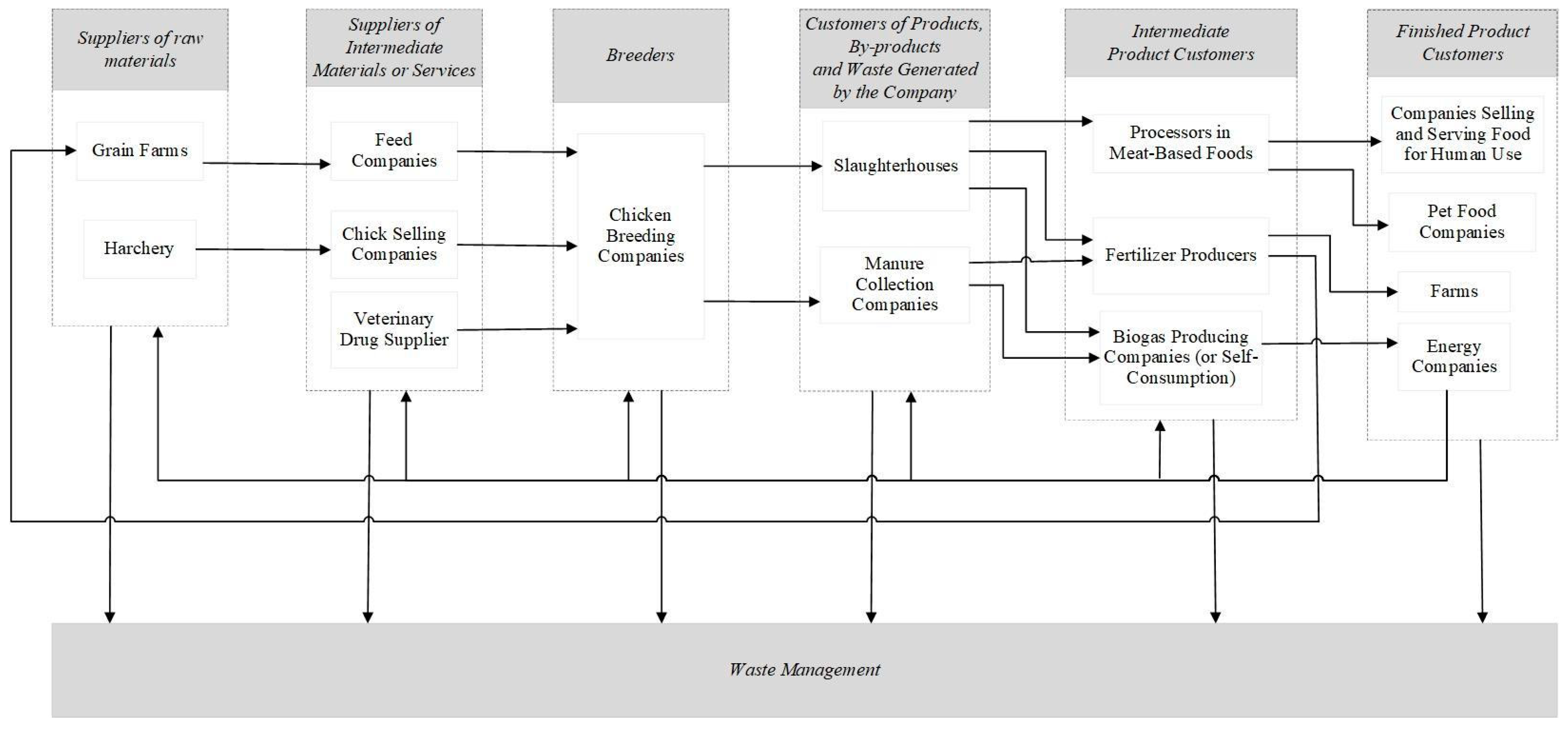

:1. Introduction

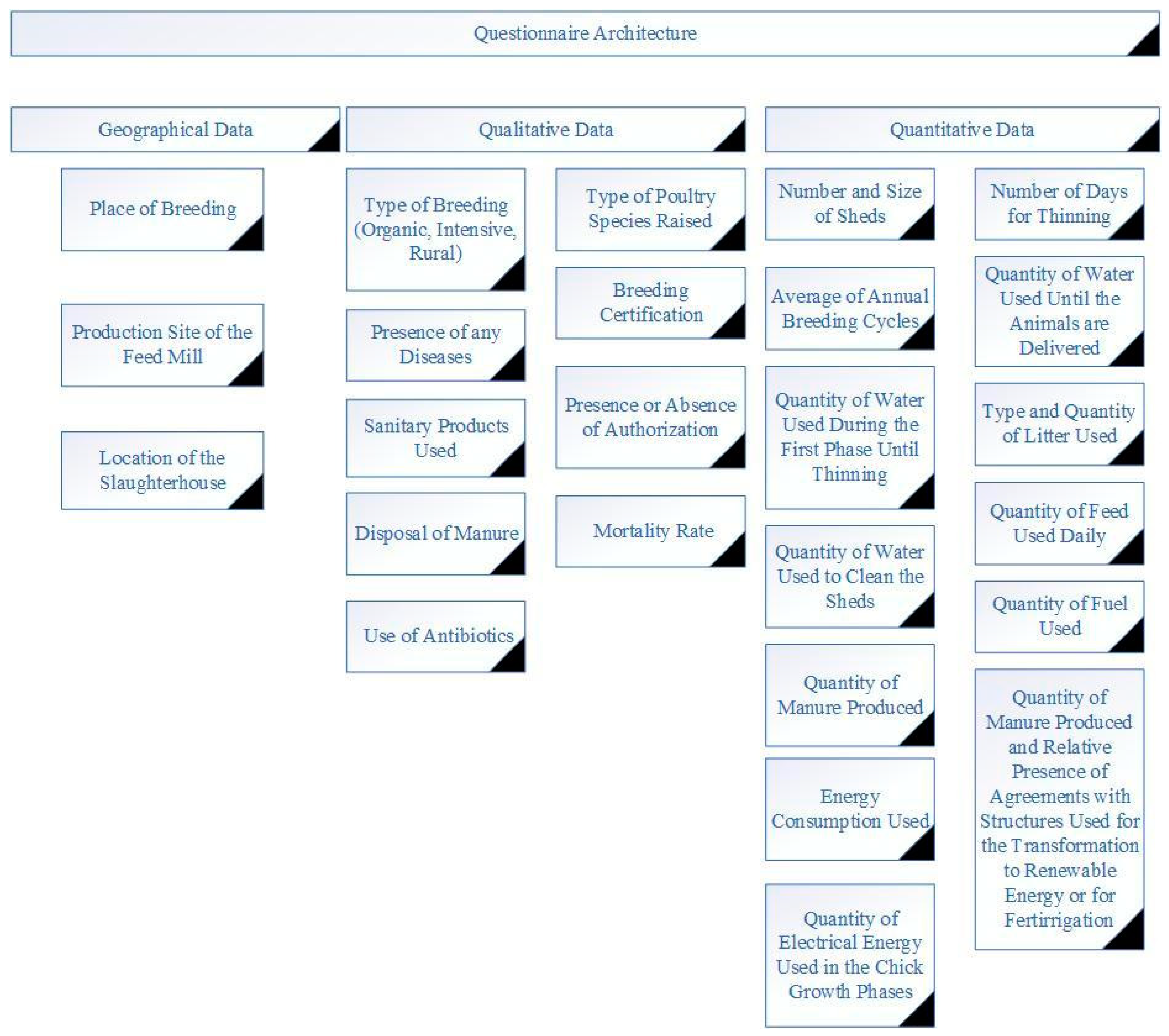

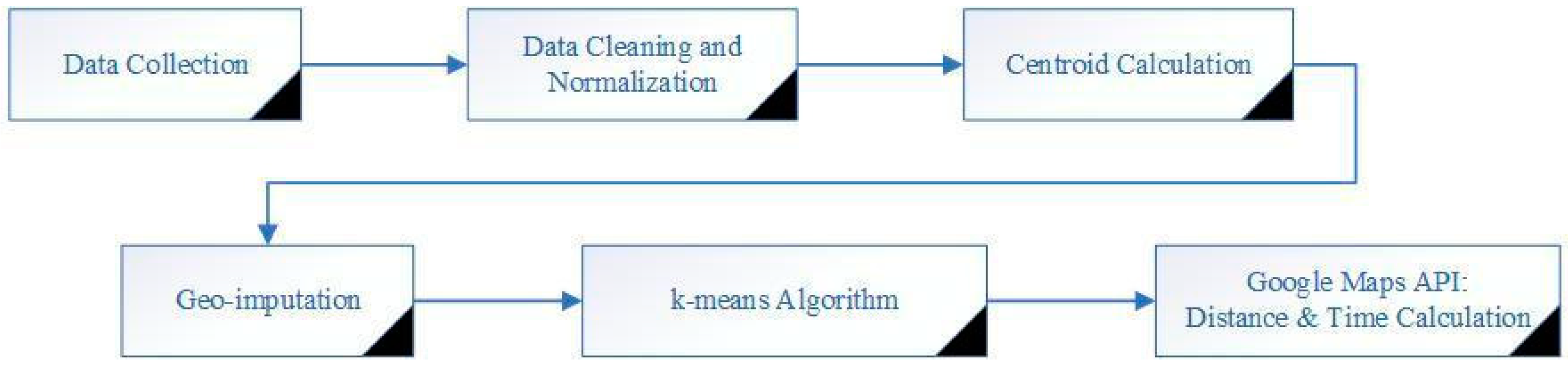

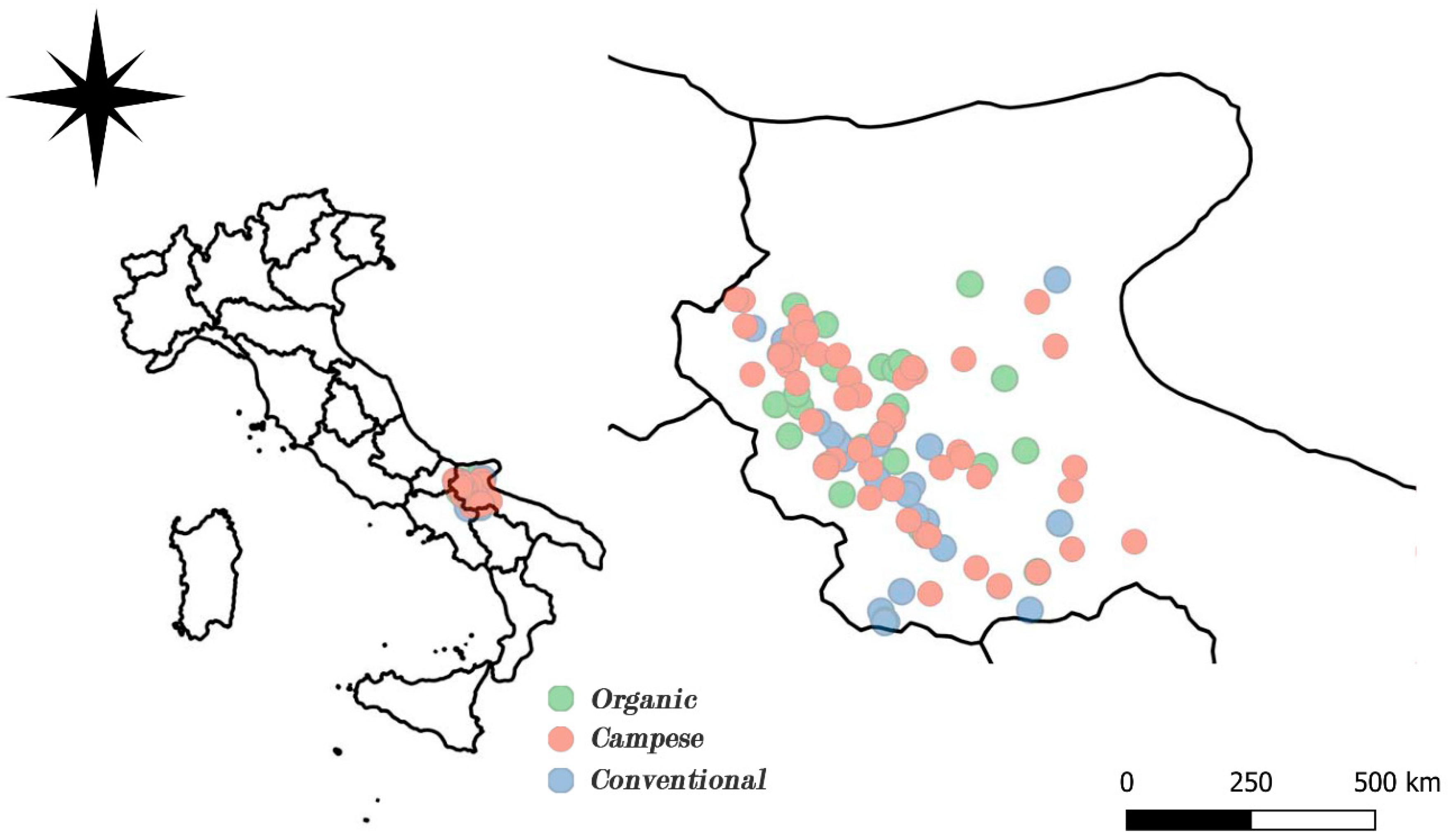

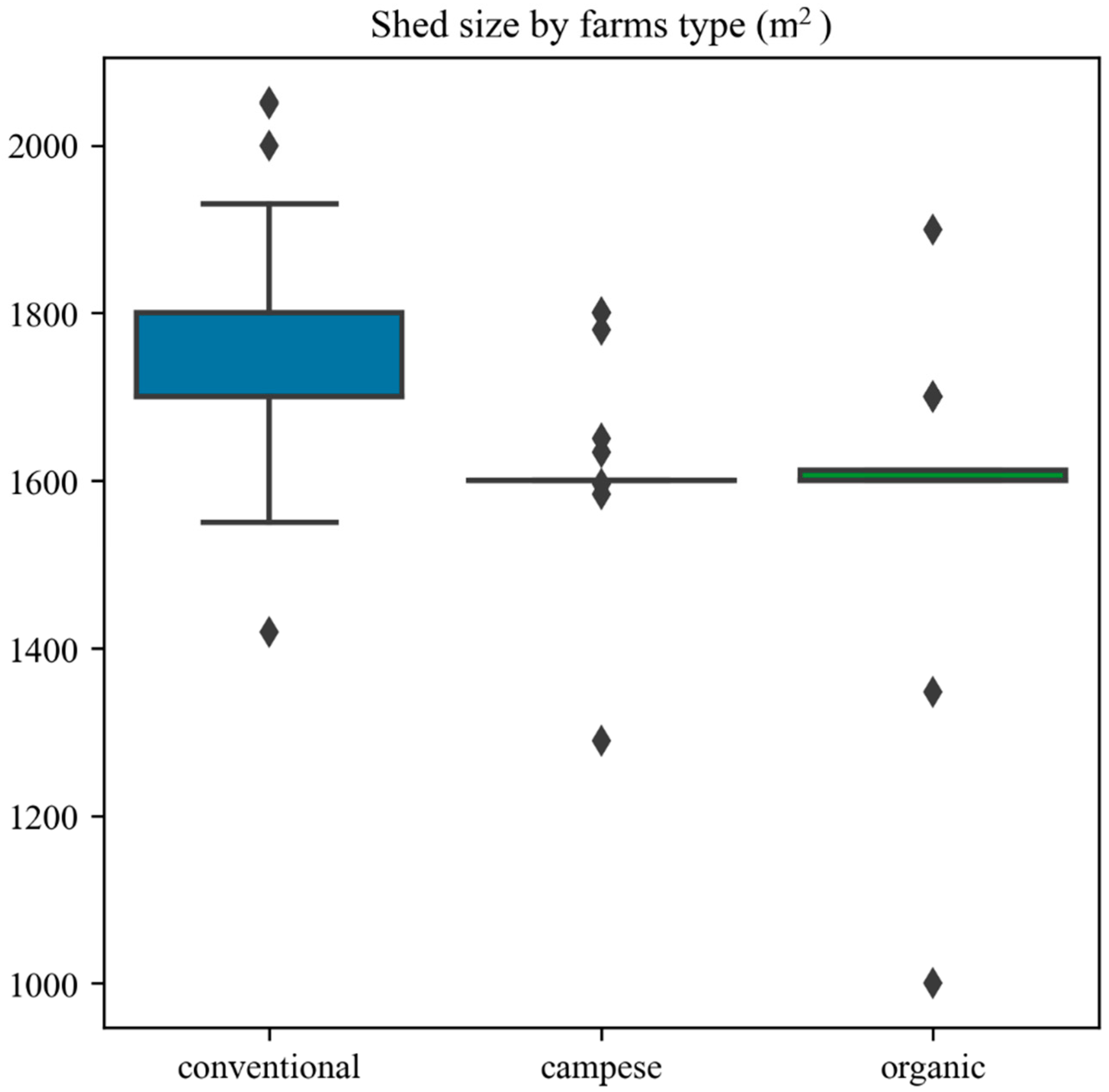

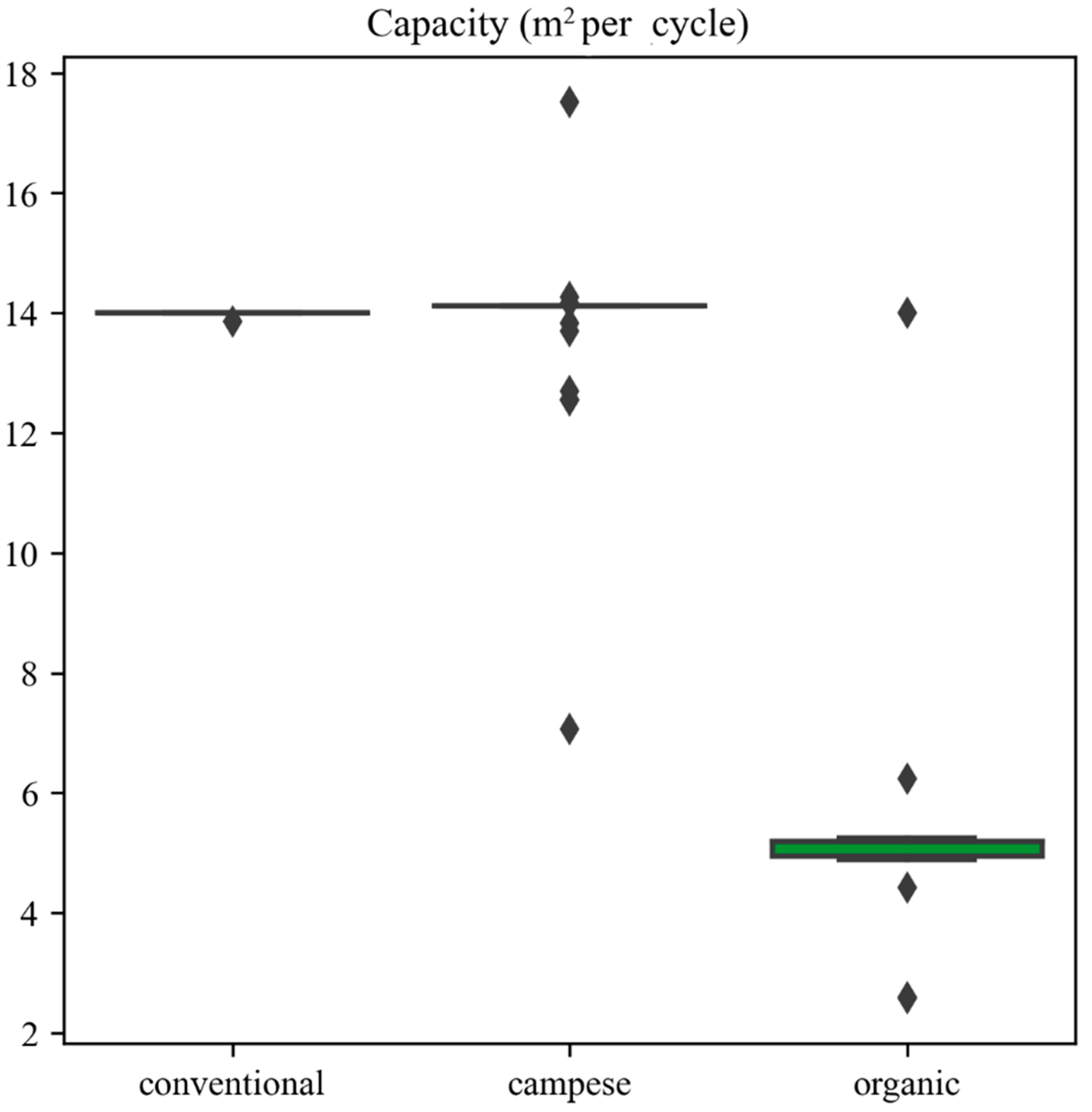

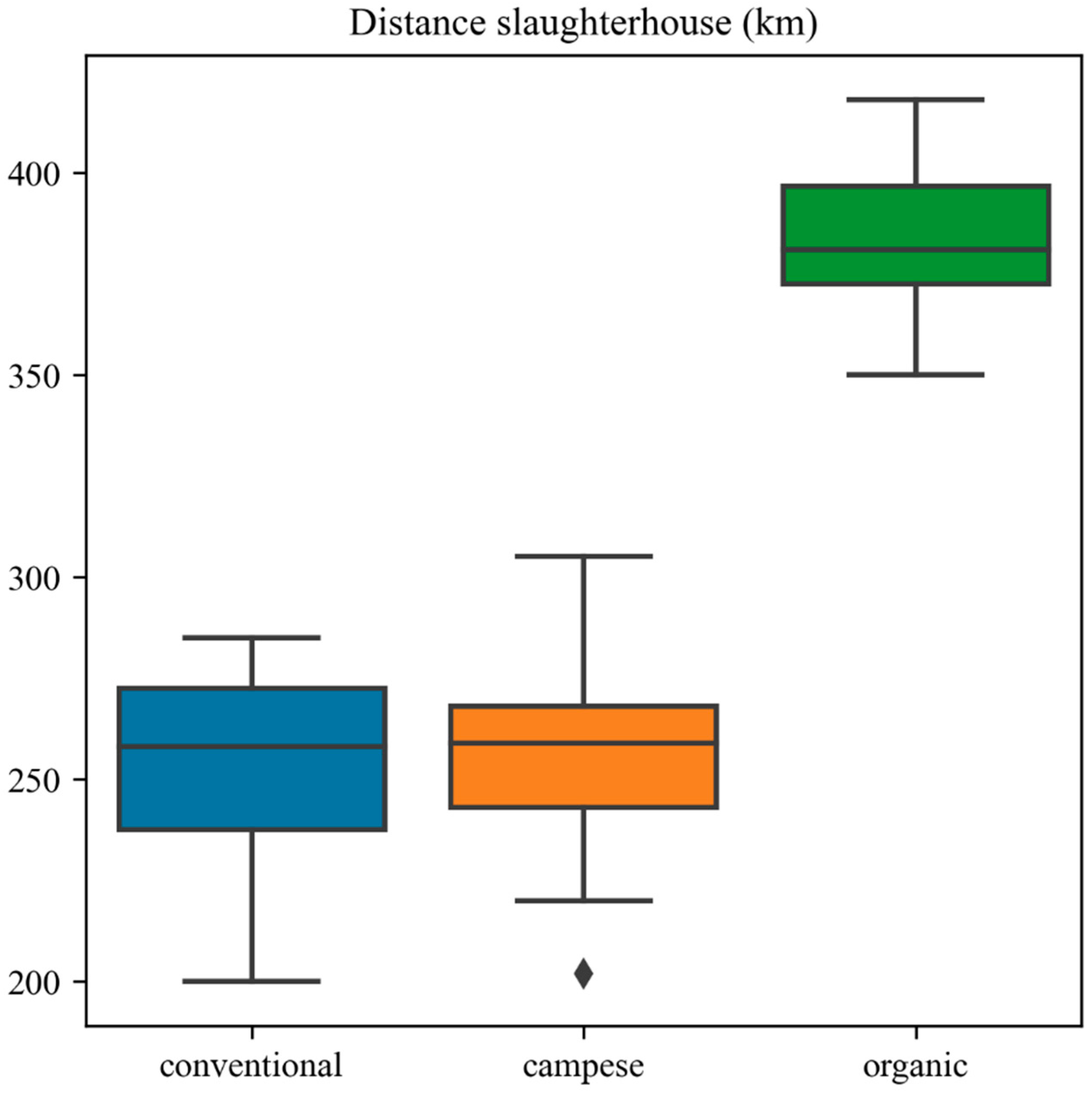

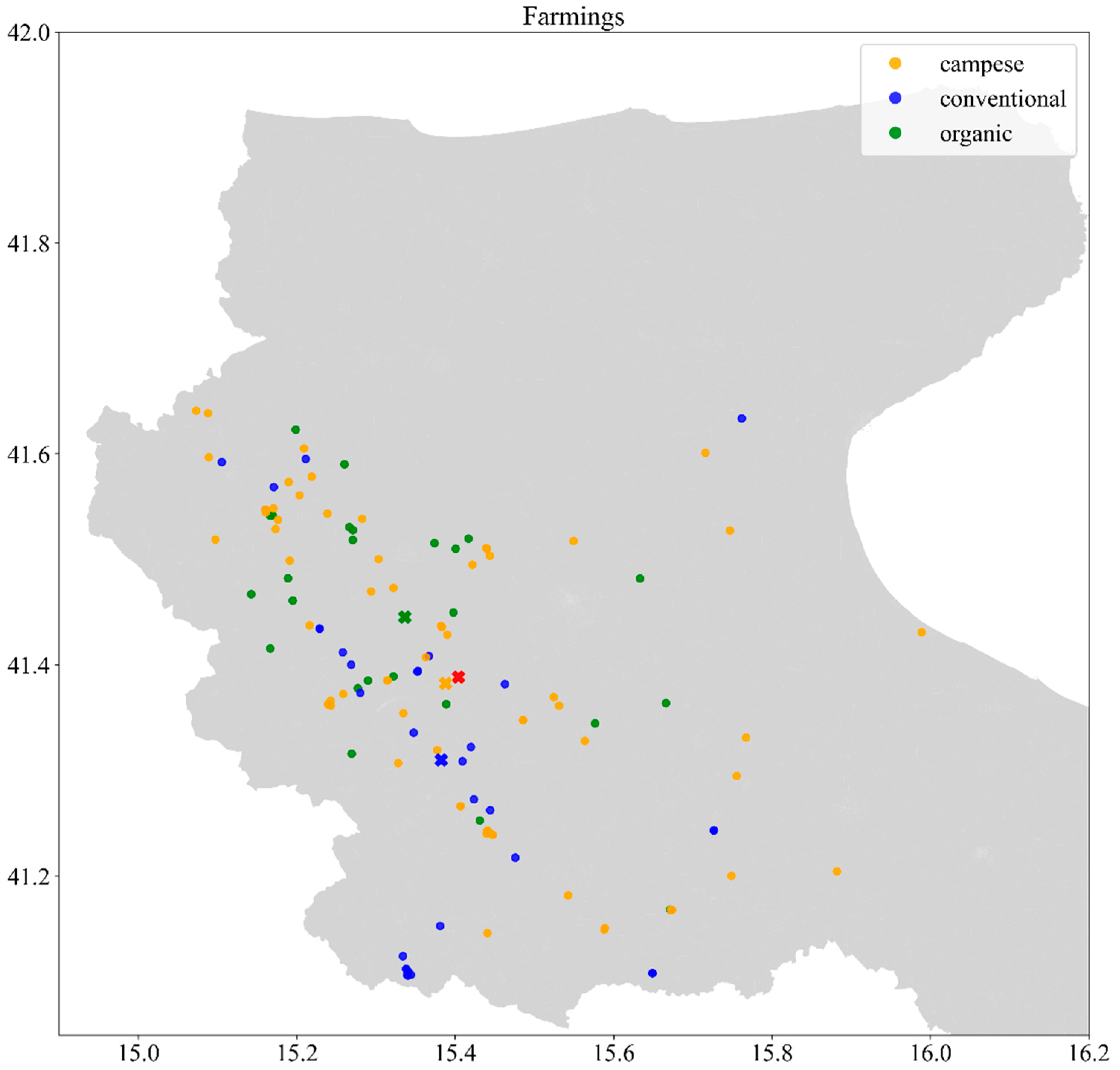

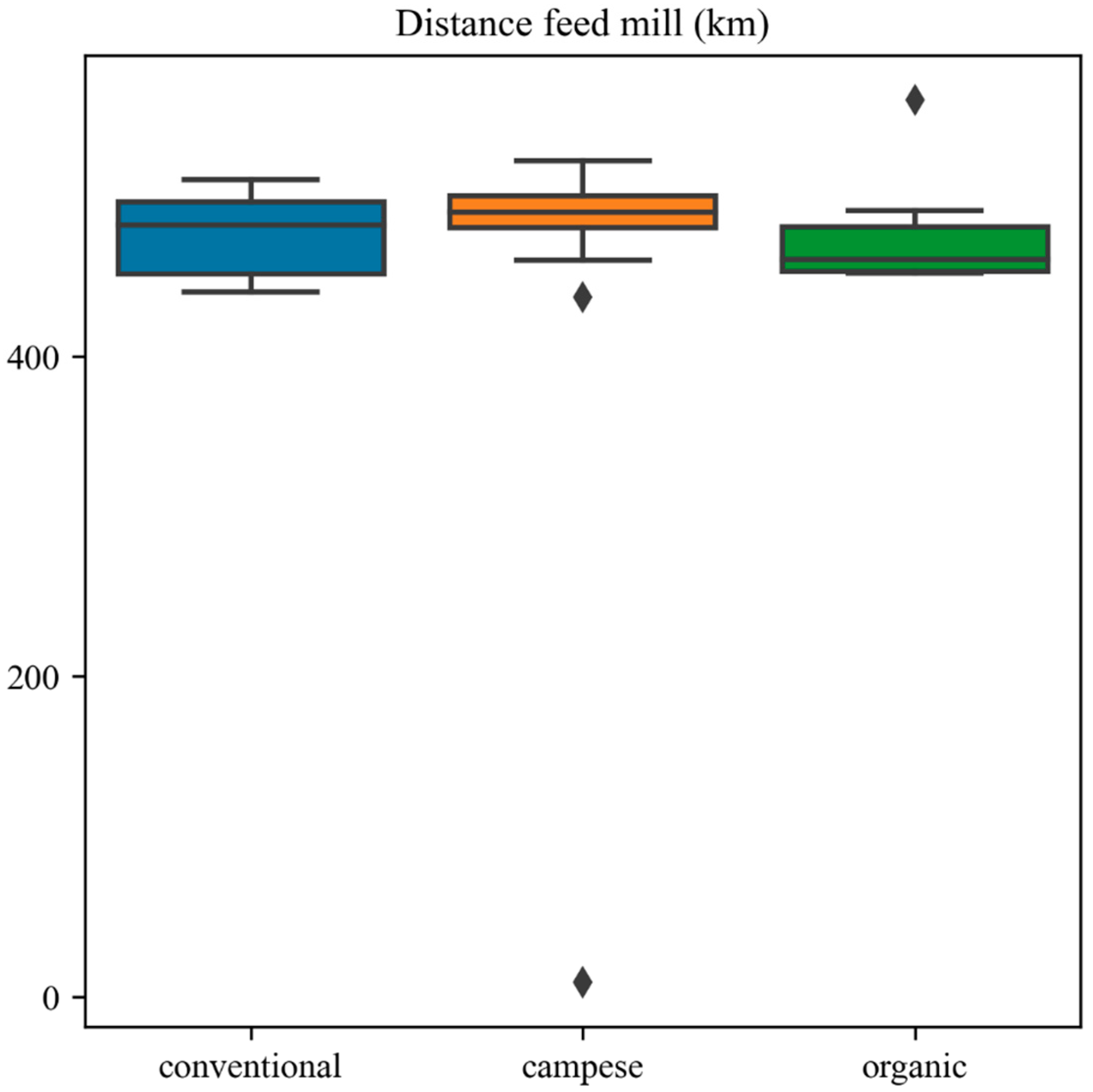

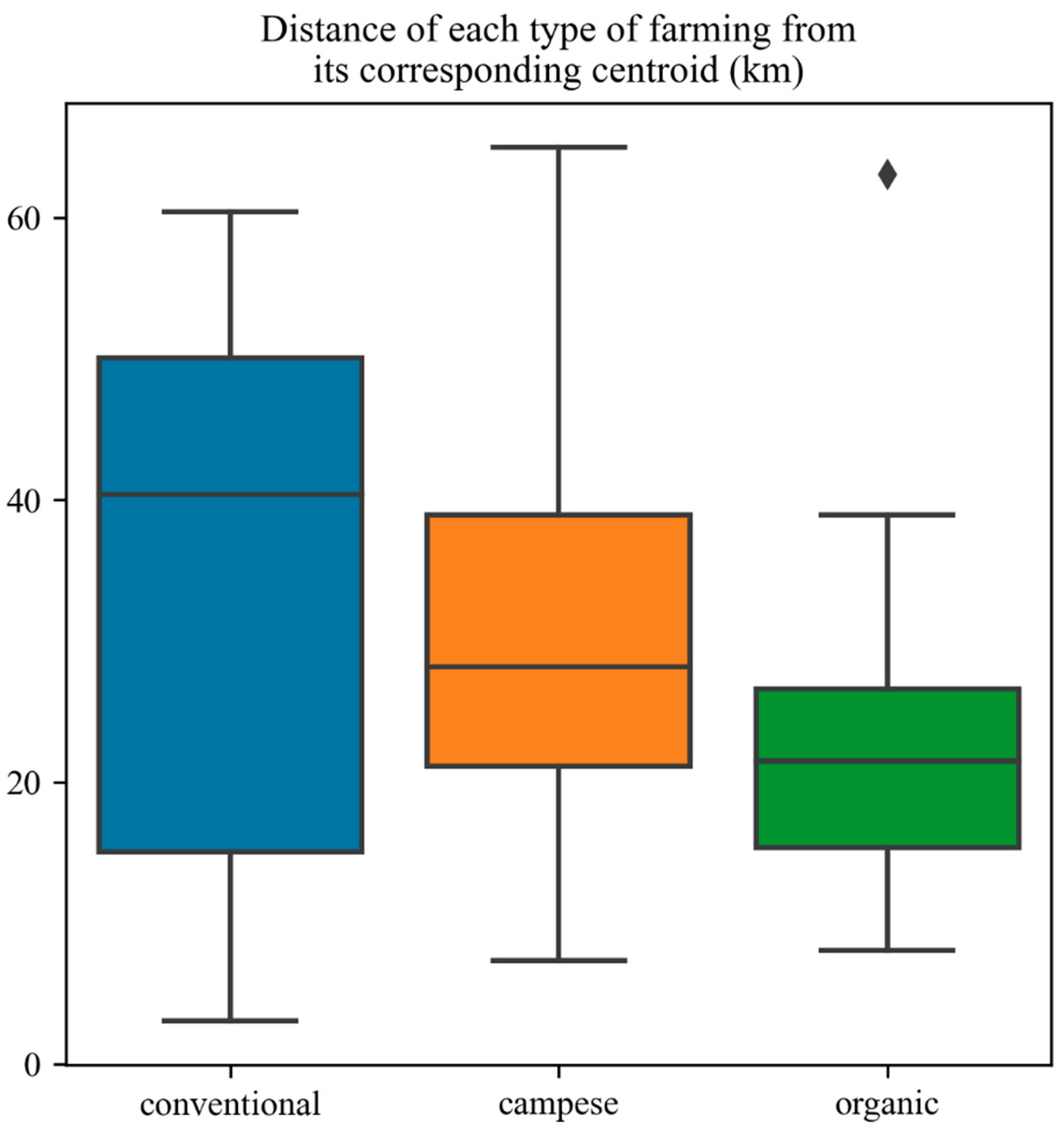

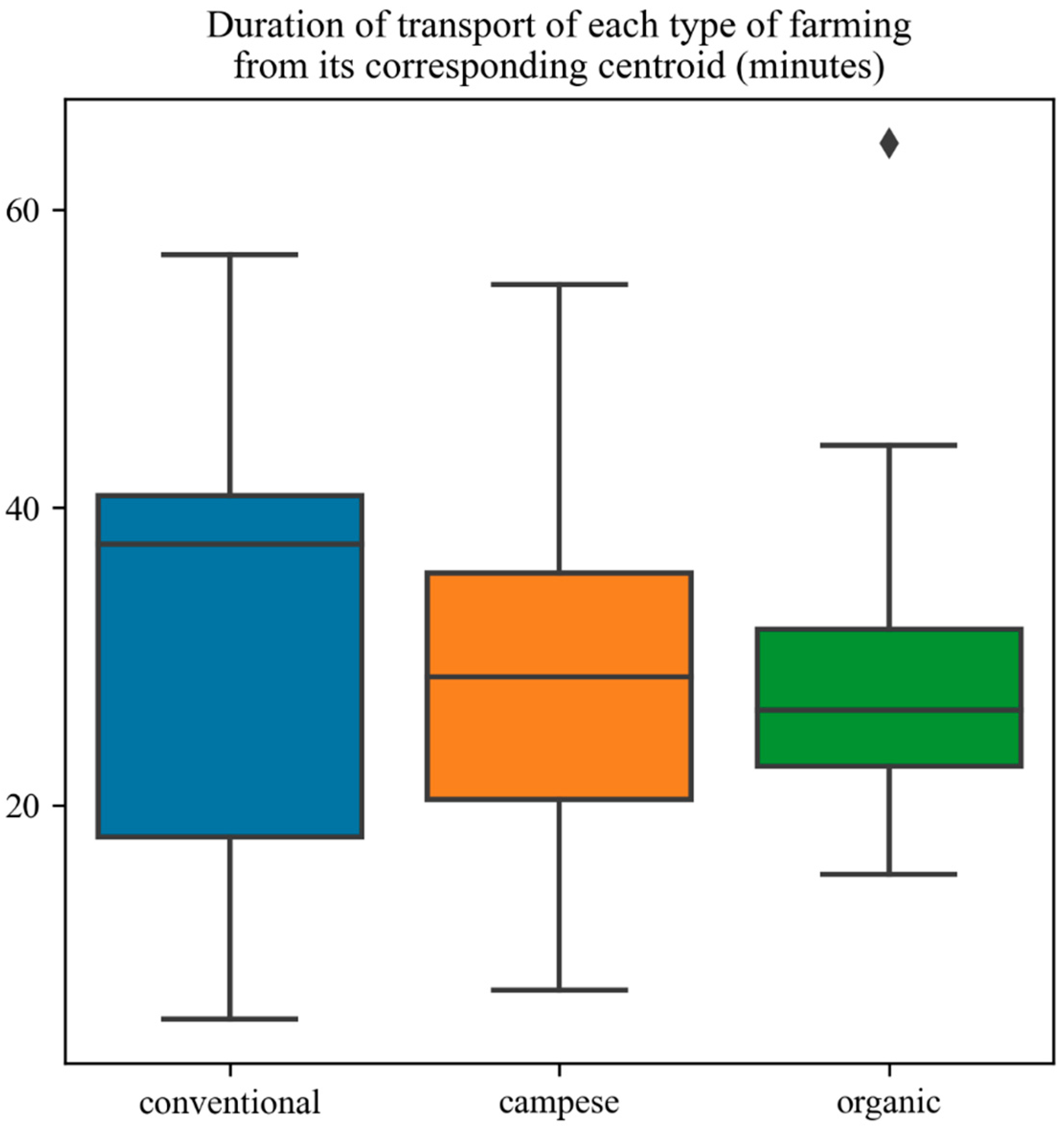

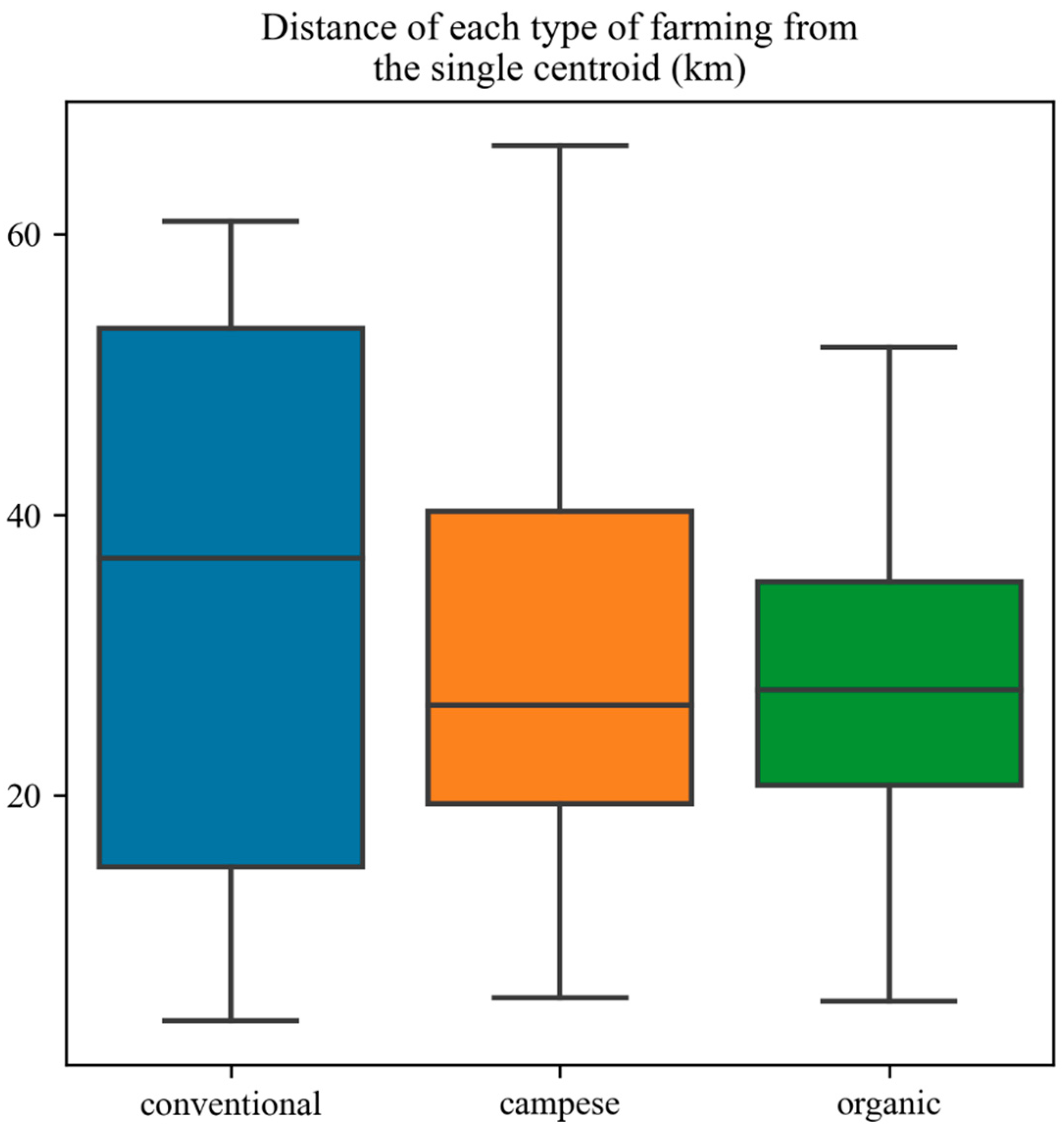

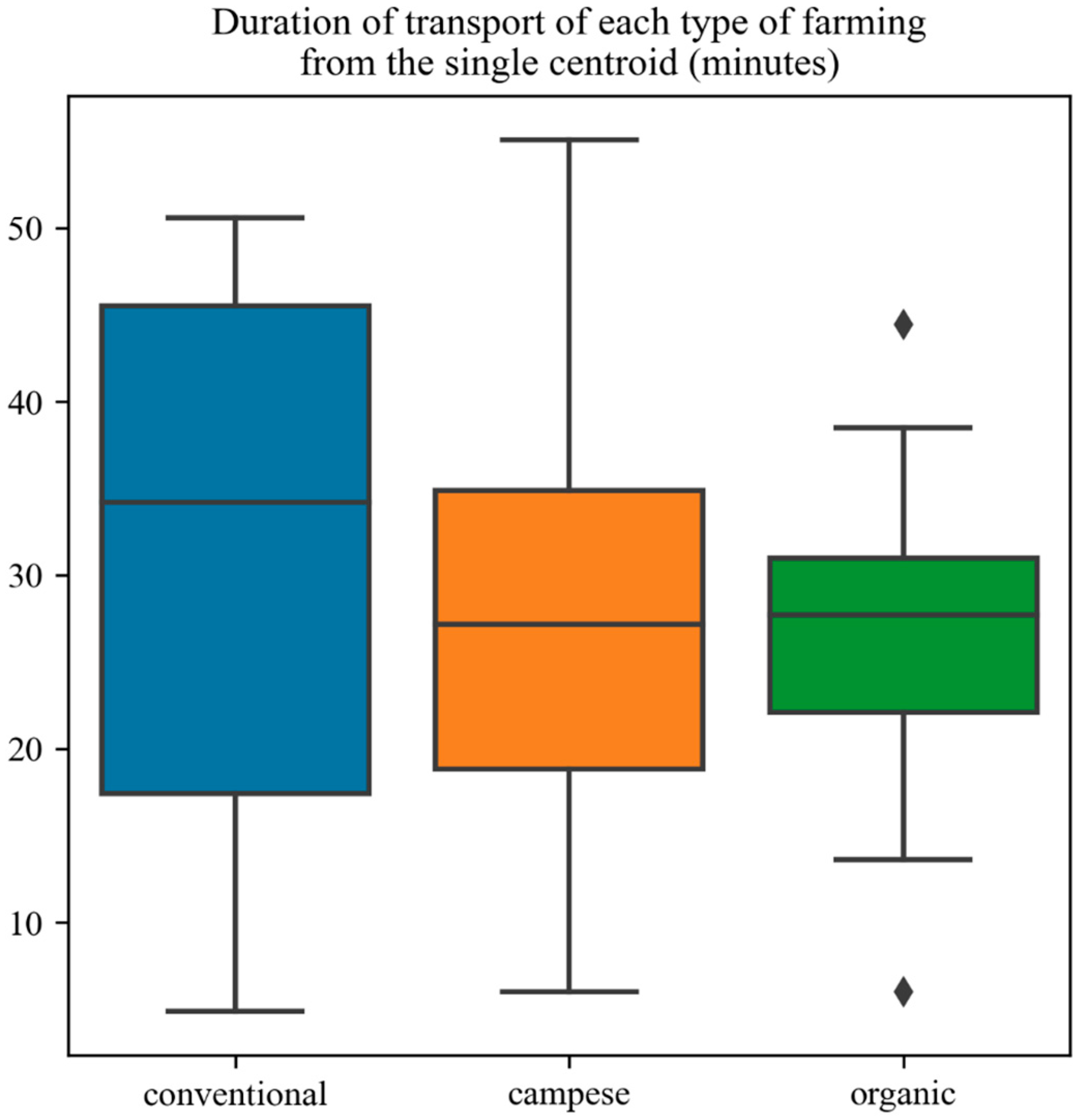

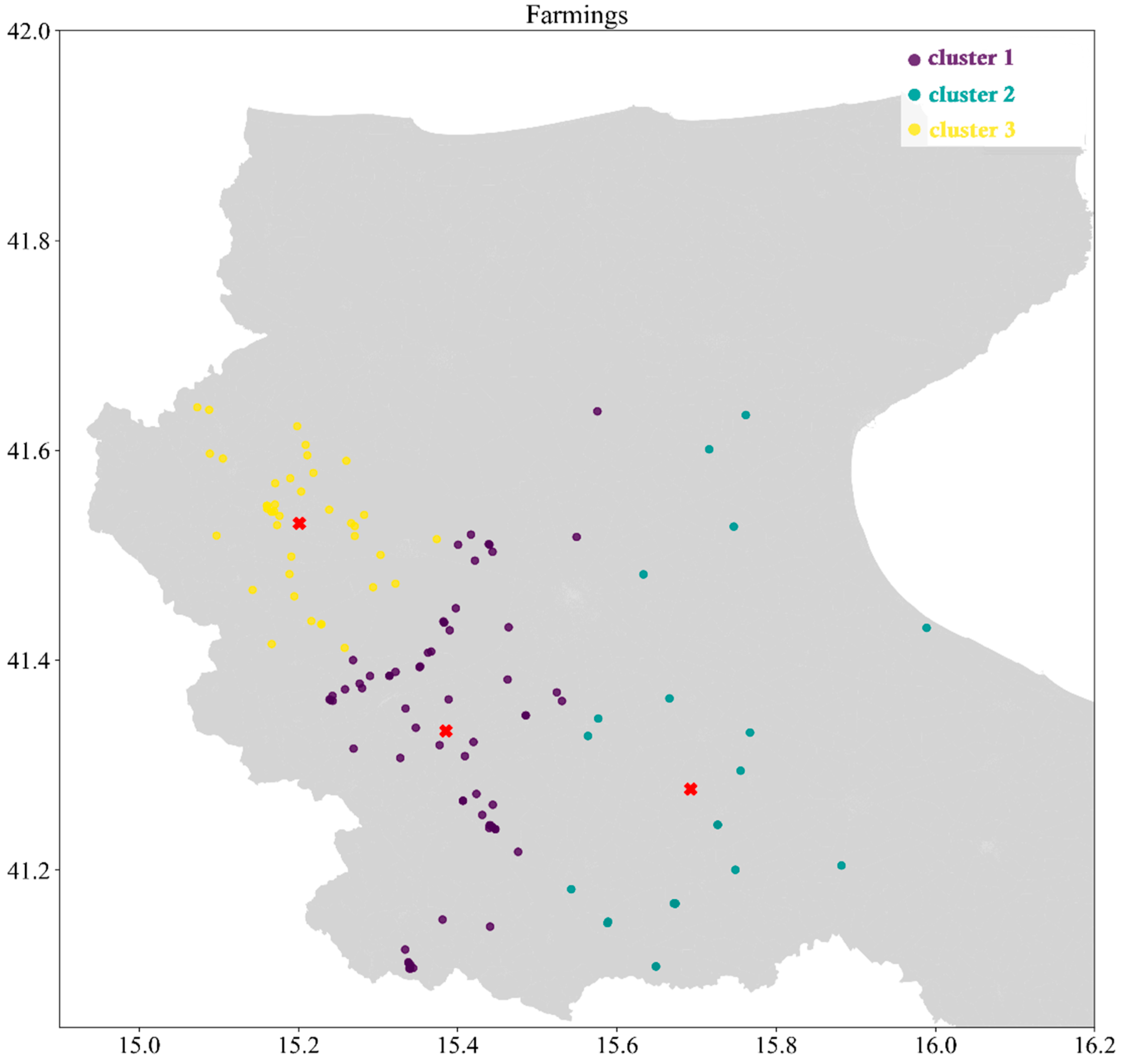

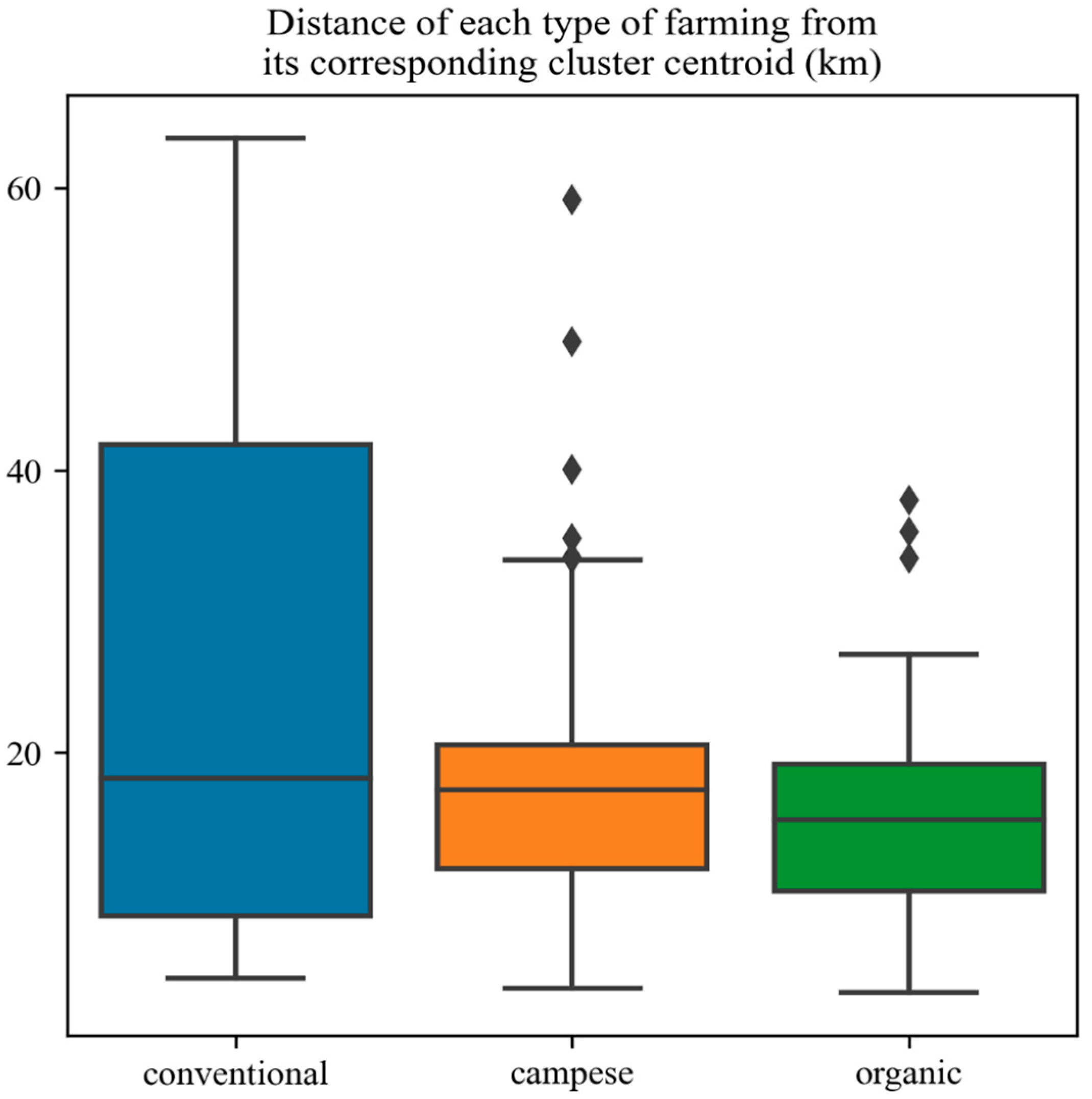

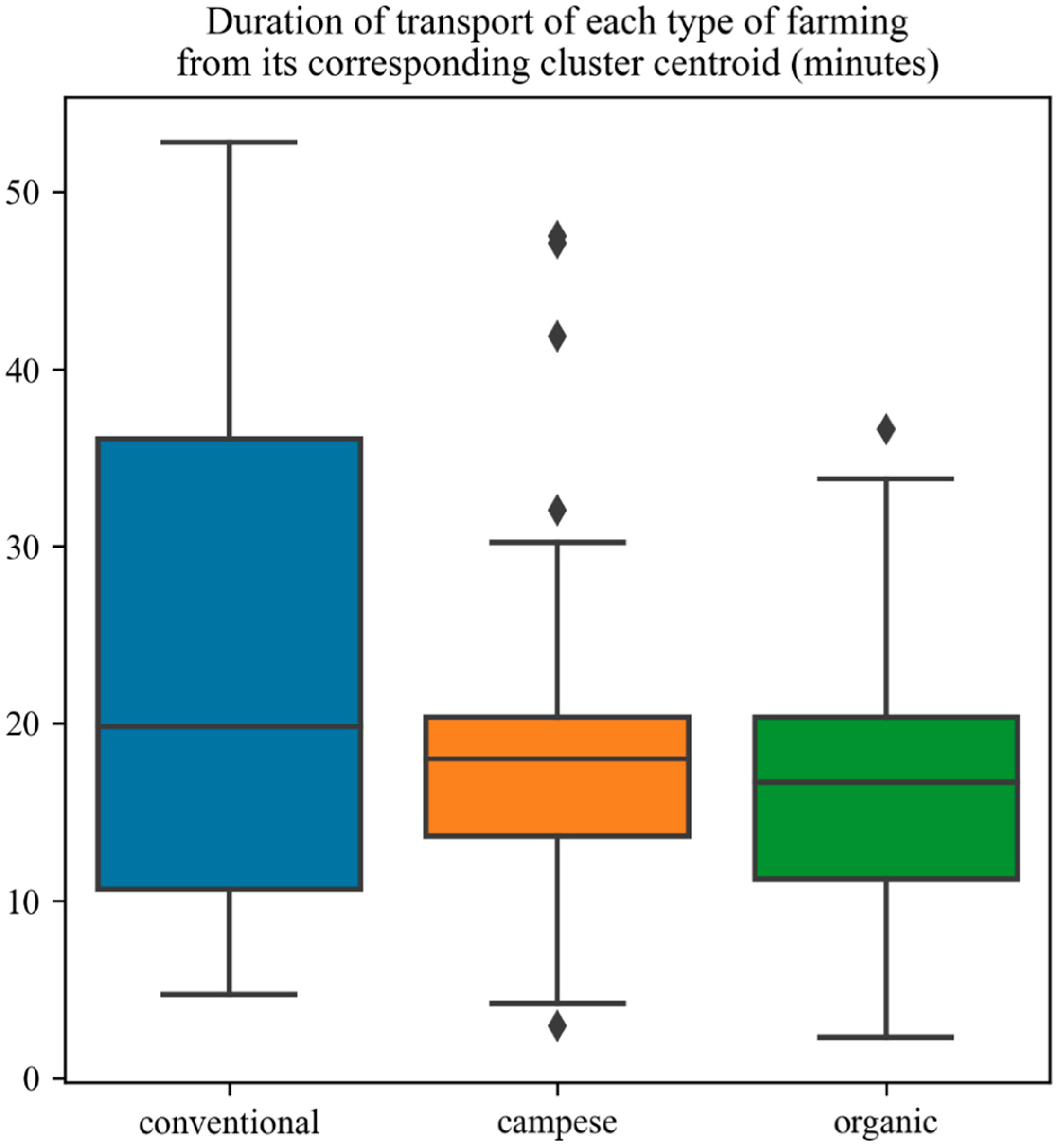

2. Material and Method

2.1. Dataset

2.2. Geo-Imputation Procedure: Centroid and k-Means Calculation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- OECD. OECD-FAO Agricultural Outlook 2022–2031. 2022. Available online: https://www.oecd.org/en/publications/oecd-fao-agricultural-outlook-2022-2031_f1b0b29c-en.html (accessed on 4 February 2025).

- FAO. Faostat. 2025. Available online: https://fao.org/faostat/en/#data (accessed on 4 February 2025).

- Unaitalia. Annual Report 2021. 2021. Available online: https://www.unaitalia.com/ (accessed on 4 February 2025). (In Italian).

- FAO (Food and Agriculture Organization) Gateway to Poultry Production and Products. Available online: https://www.fao.org/poultry-production-products/production/ru/ (accessed on 19 March 2023).

- Gulati, A.; Ganguly, K.; Wardhan, H. (Eds.) Agricultural Value Chains in India; Springer: Berlin/Heidelberg, Germany, 2022; ISBN 2198-0020 (electronic). Available online: https://link.springer.com/book/10.1007/978-981-33-4268-2 (accessed on 4 February 2025)ISSN 2198-0020.

- Khaleda, S. The poultry value chain and sustainable development of poultry microenterprises that utilize homestead lands: A case study in Gazipur, Bangladesh. In Land Use Policy; Elsevier: Amsterdam, The Netherlands, 2013; Volume 30, pp. 642–651. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0264837712000968?via%3Dihub (accessed on 4 February 2025)ISSN 0264-8377.

- Le Hoa Vo, T.; Thiel, D. Economic simulation of a poultry supply chain facing a sanitary crisis. Br. Food J. 2011, 113, 1011–1030. [Google Scholar] [CrossRef]

- Sutherland, M.; Dowlong, S.; Shaw, R.; Hickey, J.; Fraser, D.; Cameron, C.; Sutherland, I. Stress-Induced Immunomodulation in Low and High Reactive Sheep. Animals 2019, 9, 104. [Google Scholar] [CrossRef]

- ISMEA. Poultry Chain. 2021. Available online: https://www.ismeamercati.it/flex/cm/pages/ServeBLOB.php/L/IT/IDPagina/3517#MenuV (accessed on 4 February 2025). (In Italian).

- Mendes, C.M.I.; Demattê Filho, L.C.; Gameiro, A.H. Incorporating sustainability in the food supply chain: The development of a private standard of Nature Farming poultry production in Brazil. Res. Glob. 2024, 8, 100185. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. A comparative literature analysis of definitions for green and sustainable supply chain management. J. Clean. Prod. 2013, 52, 329–341. [Google Scholar] [CrossRef]

- Balasaheb Phalke, B.; Londhe, V.; Arudkar, A. A Poultry Farm Management System. Int. J. Res. Eng. Sci. Manag. 2020, 3, 41–43. Available online: https://journal.ijresm.com/index.php/ijresm/article/view/15 (accessed on 4 February 2025).

- Elson, H.A. Poultry management systems—Looking to the future. World’s Poult. Sci. J. 1988, 44, 103–111. [Google Scholar] [CrossRef]

- Khadem, M.; Shamsuzzoha, A.; Piya, S. Optimization Modeling of a Poultry Industry Supply Chain Network. Int. J. Sup. Chain. Mgt. 2017, 6, 27–32. Available online: http://excelingtech.co.uk/ (accessed on 4 February 2025).

- Nallusamy, S.; Rekha, R.S.; Balakannan, K.; Chakraborty, P.S.; Majumdar, G. A Proposed Agile Based Supply Chain Model for Poultry Based Products in India. Int. J. Poult. Sci. 2015, 14, 57–62. [Google Scholar] [CrossRef]

- Saiful Islam, M.; Khatun, R.; Ahmed, S.; Amirul Hasan, M.; Saiful Islam, M.; MAshab Uddin, A.S.; Showkat Mahmud, M. Value Chain Analysis of Processed Poultry Products (Egg and Meat) in Some Selected Areas of Bangladesh. Am. J. Rural. Dev. 2016, 4, 65–70. [Google Scholar]

- Schiavo, G.; Vinícius, M.; Rocha, S.; Dias, V.; Vaccaro GL, R.; Korzenowski, A.L. A model to manage the influence of quality on the poultry supply chain. In Proceedings of the 2015 Industrial and Systems Engineering Research Conference, Nashville, TN, USA, 21–23 October 2015; p. 1985. [Google Scholar]

- Jufiardi, J.W.; Pinagara, F.A. Analysis of supply chain management in ABC poultry using system dynamics approach. In IOP Conference Series: Materials Science and Engineering, Proceedings of the International Conference on Operations Research, Manado, Indonesia, 20–21 September 2018; Purpose-Led Publishing: College Park, MD, USA, 2018; Volume 567. [Google Scholar] [CrossRef]

- Gulati, A.; Ganguly, K.; Wardhan, H. India Studies in Business and Economics. In Agricultural Value Chains in India; Springer: Berlin/Heidelberg, Germany, 2022; Available online: https://link.springer.com/bookseries/11234 (accessed on 4 February 2025).

- Esnaola-Gonzalez, I. Semantic Technologies Towards Accountable Artificial Intelligence: A Poultry Chain Management Use Case. In Artificial Intelligence XXXVII; Bramer, M., Ellis, R., Eds.; Springer International Publishing: Berlin/Heidelberg, Germany, 2020; pp. 215–226. [Google Scholar]

- Valdokhina, S.; Vedenkina, I.; Roiter, L. Traceability as a management tool for processing poultry products. In IOP Conference Series: Earth and Environmental Science, Proceedings of the International Scientific and Practical Conference on Agrarian Economy in the Era of Globalization and Integration, Moscow, Russia, 24–25 October 2018; IOP Publishing: Bristol, UK, 2019; Volume 274. [Google Scholar] [CrossRef]

- Esnaola-Gonzalez, I.; Gómez-Omella, M.; Ferreiro, S.; Fernandez, I.; Lázaro, I.; García, E. An IoT platform towards the enhancement of poultry production chains. Sensors 2020, 20, 1549. [Google Scholar] [CrossRef]

- Grandin, T. Chapter 1—Principles for Commercial Supply Chain Managers of Livestock and Poultry. In Sustainable Meat Production and Processing; Galanakis, C.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 1–15. [Google Scholar] [CrossRef]

- Shamsuddoha, M.; Quaddus, M.; Klass, D. Sustainable poultry production process to mitigate socio-economic challenge. Humanomics 2015, 31, 242–259. [Google Scholar]

- Pohlmann, C.R.; Scavarda, A.J.; Alves, M.B.; Korzenowski, A.L. The role of the focal company in sustainable development goals: A Brazilian food poultry supply chain case study. J. Clean. Prod. 2020, 245, 118798. [Google Scholar] [CrossRef]

- Barbut, S. Live bird handling. In The Science of Poultry and Meat Processing; Barbut, S., Ed.; University of Guelph: Guelph, ON, Canada, 2015; Chapter 4. [Google Scholar]

- Jayaprakash, G.; Sathiyabarathi, M.; Arokia Robert, M.; Tamilmani, T. Transportation stress in broiler chickens. Int. J. Sci. Environ. Technol. 2016, 5, 806–809. [Google Scholar]

- El-Lethey, H.; Huber-Eicher, B.; Jungi, T.W. Exploration of stress-induced immunosuppression in chickens reveals both stress-resistant and stress-susceptible antigen responses. Vet. Immunol. Immunopathol. 2003, 95, 91–101. [Google Scholar] [CrossRef] [PubMed]

- Amadori. Il Campese Poultry Farming Practices. 2021. Available online: https://www.amadori.it/prodotti/il-campese (accessed on 4 February 2025).

- FAO. The State of Food and Agriculture 2020: Moving Forward with Sustainable Poultry Production; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020. [Google Scholar]

- Beia, S.I.; Tăpăloagă, D.; Șonea, C.; Gheorghe-Irimia, R.A.; Roșu, P.M.; Al Dulaimi MK, H.; Tăpăloagă, P.R. Organic vs. conventional: A comparative review of health-related welfare issues and their economic impact on poultry production. In Scientific Papers Series Management, Economic Engineering in Agriculture and Rural Development; University of Agronomic Sciences and Veterinary Medicine of Bucharest: Bucharest, Romani, 2024; Volume 24, ISSN 2284-7995, E-ISSN 2285-3952. [Google Scholar]

- Burkholder, K.M.; Thompson, K.L.; Einstein, M.E.; Applegate, T.J.; Patterson, J.A. Influence of stressors on normal intestinal microbiota, intestinal morphology, and susceptibility to Salmonella enteritidis colonization in broilers. Poul. Sci. 2008, 87, 1734–1741. [Google Scholar]

- Lyte, J.M.; Martinez, D.A.; Robinson, K.; Donoghue, A.M.; Daniels, K.M.; Lyte, M. A neurochemical biogeography of the broiler chicken intestinal tract. Poult. Sci. 2022, 101, 01671. [Google Scholar]

- Pullinger, G.D.; van Diemen, P.M.; Carnell, S.C.; Davies, H.; Lyte, M.; Stevens, M.P. 6-hydroxydopamine-mediated release of norepinephrine increases faecal excretion of Salmonella enterica serovar Typhimurium in pigs. Vet. Res. 2010, 41, 68. [Google Scholar] [CrossRef]

- Korver, D.L. Review: Current challenges in poultry nutrition, health, and welfare. Animal 2023, 2, 100755. [Google Scholar] [CrossRef]

- Berghout, J.; Roland, W.; Vollebregt, M.; Koene, M.; de Jong, I. Towards a safe and sustainable poultry production chain. Wagening. Livest. Res. 2018, 1126, 542165. [Google Scholar]

- Leinonen, I.; Kyriazakis, I. How can we improve the environmental sustainability of poultry production? Proc. Nutr. Soc. 2016, 75, 265–273. [Google Scholar] [CrossRef]

- Vaarst, M.; Steenfeldt, S.; Horsted, K. Sustainable development perspectives of poultry production. World’s Poult. Sci. J. 2015, 71, 609–620. [Google Scholar] [CrossRef]

- Bozzo, G.; Barrasso, R.; Ferorelli, D.; Gassi, V.; Russo, R.; Celentano, F.E. Animal Welfare Policies and Human Rights in the Context of Slaughter Procedures. Agriculture 2021, 11, 442. [Google Scholar] [CrossRef]

- van Huika, M.M.; Kling-Eveillardb, F.; Prutzerc, M.; Bocka, B.B.; Dockès, A.C. Attitudes of cattle, pig and poultry farmers in France, the Netherlands and Sweden towards Animal Welfare. In Proceedings of the ESRS Congress 2007, Wageningen, The Netherlands, 20–24 August 2007. [Google Scholar]

- Bonaudo, T.; Coutinho, C.A.; Poccard Chapuis, R.; Lescoat, P.; Lossouarn, J.; Tourrand, J.F. Poultry industry and the sustainable development of territories: What links? What conditions? In Proceedings of the CIRAD, Montpellier, France, 28–30 June 2010. [Google Scholar]

- Costantini, M.; Ferrante, V.; Guarino, M.; Bacenetti, J. Environmental sustainability assessment of poultry productions through life cycle approaches: A critical review. Trends Food Sci. Technol. 2021, 110, 201–212. [Google Scholar]

- Géron, A. Hands-On Machine Learning with Scikit-Learn, Keras, and TensorFlow, 2nd ed.; O’Reilly Media, Inc.: Sebastopol, CA, USA, 2019. [Google Scholar]

- Raschka, S.; Mirjalili, V. Python Machine Learning, 3rd ed.; Packt: Birmingham, UK, 2019. [Google Scholar]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis, 7th ed.; Pearson Education Limited: Harlow, UK, 2014. [Google Scholar]

- Arthur, D.; Vassilvitskii, S. k-means++: The advantages of careful seeding. In Proceedings of the Eighteenth Annual ACM-SIAM Symposium on Discrete Algorithms, New Orleans, LA, USA, 7–9 January 2007; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 2007. [Google Scholar]

- Henry, K.A.; Boscoe, F.P. Estimating the accuracy of geographical imputation. Int. J. Health Geogr. 2008, 7, 3. [Google Scholar] [CrossRef] [PubMed]

- Na, S.; Xumin, L.; Yong, G. Research on k-means Clustering Algorithm: An Improved k-means Clustering Algorithm. In Proceedings of the 2010 Third International Symposium on Intelligent Information Technology and Security Informatics, Ji’an, China, 2–4 April 2010. [Google Scholar]

- Sinaga, K.P.; Yang, M. Unsupervised K-Means Clustering Algorithm. IEEE Access 2020, 8, 80716–80727. [Google Scholar] [CrossRef]

- Hu, H.; Liu, J.; Zhang, X.; Fang, M. An Effective and Adaptable K-means Algorithm for Big Data Cluster Analysis. Pattern Recognit. 2023, 139, 109404. [Google Scholar] [CrossRef]

- Likasa, A.; Vlassisb, N.; Verbeek, J. The global k-means clustering algorithm. Pattern Recognit. 2003, 36, 451–461. [Google Scholar]

- Pedregosa, F.; Varoquaux, G.; Gramfort, A.; Michel, V.; Thirion, B.; Grisel, O.; Blondel, M.; Prettenhofer, P.; Weiss, R.; Dubourg, V.; et al. Scikit-learn: Machine Learning in Python. J. Mach. Learn. Res. 2011, 12, 2825–2830. [Google Scholar]

- Elkan, C. Using the Triangle Inequality to Accelerate. In Proceedings of the Proceedings of the Twentieth International Conference on Machine Learning (ICML-2003), Washington, DC, USA, 21–24 August 2003. [Google Scholar]

- Böttcher, A.; Wenzel, D. The Frobenius norm and the commutator. Linear Algebra Its Appl. 2008, 429, 1864–1885. [Google Scholar]

- Custódio, A.L.; Rocha, H.; Vicente, L.N. Incorporating minimum Frobenius norm models in direct search. Comput. Optim. Appl. 2010, 46, 265–278. [Google Scholar] [CrossRef]

- Zou, L. Linear and Multilinear Algebra; Talylor Francis Group: Abingdon, UK, 2012; Volume 60, pp. 27–31. [Google Scholar]

- Delabouglise, A.; Nguyen-Vaan-Yen, B.; Le Thanh, N.T.; Xuyen, H.T.A.; Tuyet, P.N.; Lam, H.M.; Boni, M.F. Poultry population dynamics and mortality risks in smallholder farms of the Mekong river delta region. BMC Vet. Res. 2019, 15, 205. [Google Scholar] [PubMed]

- Vecerek, V.; Voslarova, E.; Conte, F.; Vecerkova, L.; Bedanova, I. Negative Trends in Transport-related Mortality Rates in Broiler Chickens. Asian-Australas J. Anim. Sci. 2016, 29, 1796–1804. [Google Scholar] [PubMed]

- Gou, Z.; Abouelezz, K.F.M.; Fan, Q.; Li, L.; Lin, X.; Wang, Y.; Cui, X.; Ye, J.; Masoud, M.A.; Jiang, S.; et al. Physiological effects of transport duration on stress biomarkers and meat quality of medium-growing Yellow broiler chickens. Animal 2021, 15, 100079. [Google Scholar]

- Vecerek, V.; Grbalova, S.; Voslarova, E.; Janackova, B.; Malena, M. Effects of travel distance and the season of the year on death rates in broilers transported to poultry processing plants. Poult. Sci. 2006, 85, 1881–1884. [Google Scholar]

- Fiebig, L.; Smieszek, T.; Saurina, J.; Hattendorf, J.; Zinsstag, J. Contacts between poultry farms, their spatial dimension and their relevance for avian influenza preparedness. Geospat. Health 2009, 4, 79–95. [Google Scholar]

- Resurreccion, A. Sensory aspects of consumer choices for meat and meat products. Meat Sci. 2004, 66, 11–20. [Google Scholar] [PubMed]

- Zhu, X.; Xu, X.; Min, X.; Zhou, G. Occurrence and characterization of pale, soft, exudative-like broiler muscle commercially produced in China. J. Integr. Agric. 2012, 11, 1384–1390. [Google Scholar]

- Schwartzkopf-Genswein, K.; Faucitano, L.; Dadgar, S.; Shand, P.; González, L.; Crowe, T. Road transport of cattle, swine and poultry in North America and its impact on animal welfare, carcass and meat quality: A review. Meat Sci. 2012, 92, 227–243. [Google Scholar]

- Xing, T.; Gao, F.; Tume, R.K.; Ghou, G.; Xu, X. Stress effects on meat quality: A mechanistic perspective. Compr. Rev. Food Sci. Food Saf. 2019, 18, 380–401. [Google Scholar]

- Xing, T.; Zhao, Z.; Zhao, X.; Zhuang, S.; Xu, X. Phosphoproteome analysis of sarcoplasmic and myofibrillar proteins in stress-induced dysfunctional broiler pectoralis major muscle. Food Chem. 2020, 319, 126531. [Google Scholar] [CrossRef]

- Scheffler, T.; Gerrard, D. Mechanisms controlling pork quality development: The biochemistry controlling postmortem energy metabolism. Meat Sci. 2007, 77, 7–16. [Google Scholar] [CrossRef] [PubMed]

- Xing, T.; Zhao, X.; Wang, P.; Chen, H.; Xu, X.; Zhou, G. Different oxidative status and expression of calcium channel components in stress-induced dysfunctional chicken muscle. J. Anim. Sci. 2017, 95, 1565–1573. [Google Scholar] [CrossRef] [PubMed]

- EFSAPanel on Biological Hazards (BIOHAZ); Koutsoumanis, K.; Allende, A.; Álvarez-Ordóñez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Davies, R.; De Cesare, A.; Herman, L.; et al. Transmission of antimicrobial resistance (AMR) during animal transport. EFSA J. 2022, 20, e07586. [Google Scholar] [CrossRef]

- EFSA BIOHAZ Panel (EFSA Panel on Biological Hazards); Koutsoumanis, K.; Allende, A.; Alvarez-Ordonez, A.; Bolton, D.; Bover-Cid, S.; Chemaly, M.; Davies, R.; De Cesare, A.; Herman, L.; et al. Role played by the environment in the emergence and spread of antimicrobial resistance (AMR) through the food chain. EFSA J. 2021, 19, e06651. [Google Scholar] [CrossRef]

- Park, M.; Britton, D.; Daley, W.; McMurray, G.; Navaei, M.; Samoylov, A.; Usher, C.; Xu, J. Artificial intelligence, sensors, robots, and transportation systems drive an innovative future for poultry broiler and breeder management. Anim. Front. 2022, 12, 40–48. [Google Scholar] [CrossRef]

- Amicarelli, V.; Geatti, P.; Bux, C. The Circular Economy Potential of Spent Hens’ Co-Products and By-Products in Italy by Material Flow Analysis. Environments 2023, 10, 137. [Google Scholar] [CrossRef]

- Cappone, E.E.; Zambotto, V.; Mota-Gutierrez, J.; Soglia, D.; Daniele, G.M.; Cianciabella, M.; Pieronic, A.; Soukand, R.; Penasa, M.; Buccioni, A.; et al. Native Italian poultry products: The factors influencing consumer perceptions. Ital. J. Anim. Sci. 2025, 24, 347–360. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cappelletti, G.M.; Chiara, F.; Russo, C.; Russo, P.; D’Emilio, A.G.; Costagliola, A.; Liguori, G. An Organizational Model of a Food Production Chain: A Case Study in the Poultry Sector in Foggia (Italy). Sustainability 2025, 17, 2984. https://doi.org/10.3390/su17072984

Cappelletti GM, Chiara F, Russo C, Russo P, D’Emilio AG, Costagliola A, Liguori G. An Organizational Model of a Food Production Chain: A Case Study in the Poultry Sector in Foggia (Italy). Sustainability. 2025; 17(7):2984. https://doi.org/10.3390/su17072984

Chicago/Turabian StyleCappelletti, Giulio Mario, Filomena Chiara, Carlo Russo, Pietro Russo, Antonio Giovanni D’Emilio, Anna Costagliola, and Giovanna Liguori. 2025. "An Organizational Model of a Food Production Chain: A Case Study in the Poultry Sector in Foggia (Italy)" Sustainability 17, no. 7: 2984. https://doi.org/10.3390/su17072984

APA StyleCappelletti, G. M., Chiara, F., Russo, C., Russo, P., D’Emilio, A. G., Costagliola, A., & Liguori, G. (2025). An Organizational Model of a Food Production Chain: A Case Study in the Poultry Sector in Foggia (Italy). Sustainability, 17(7), 2984. https://doi.org/10.3390/su17072984