A Review of Applications of Nanocellulose to Preserve and Protect Cultural Heritage Wood, Paintings, and Historical Papers

Abstract

1. Introduction

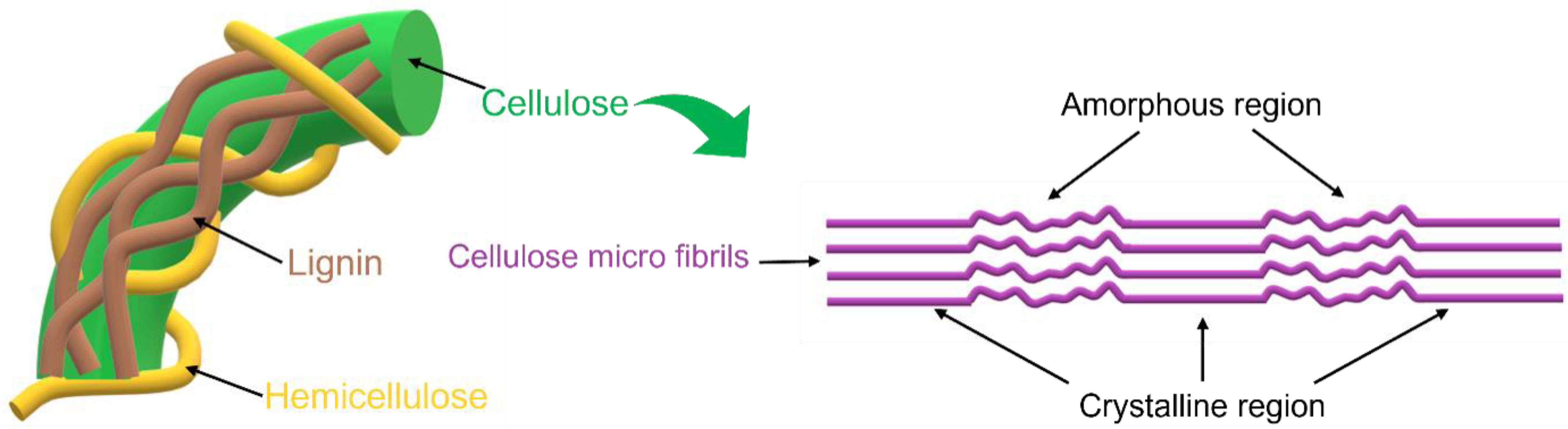

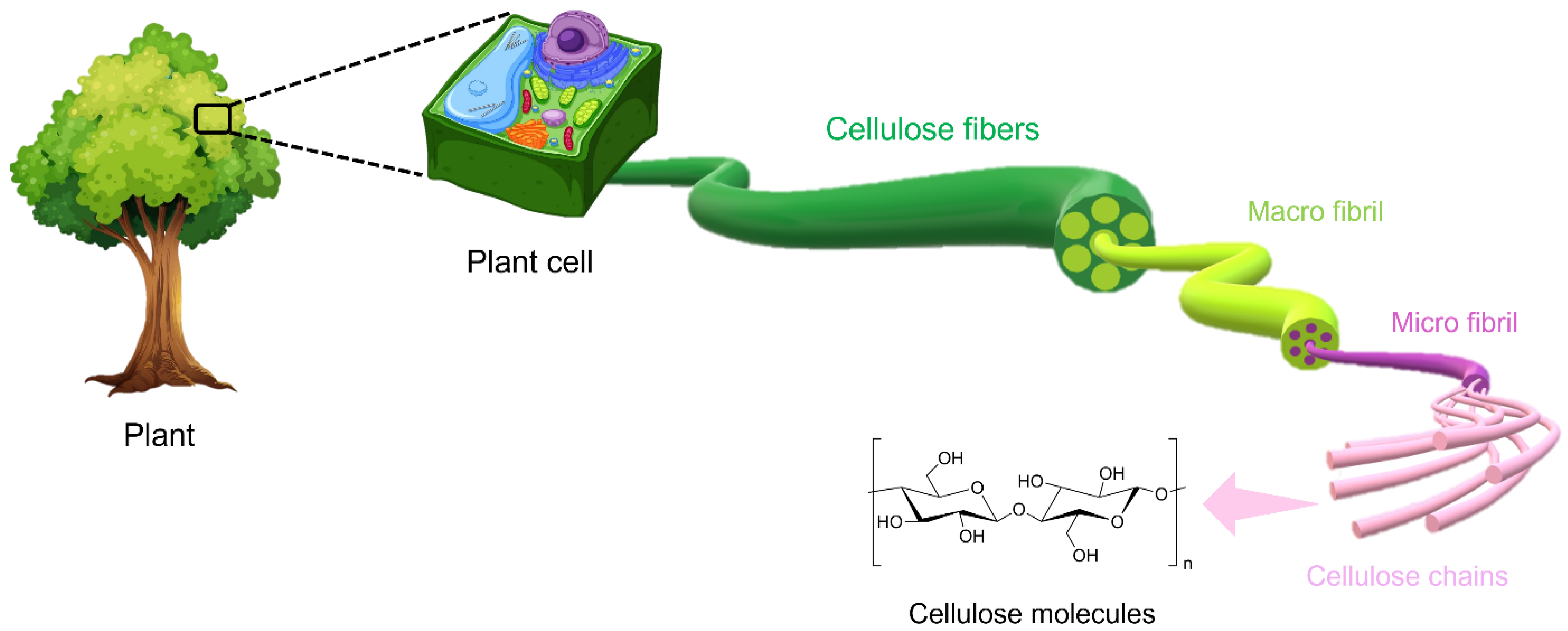

2. Cellulose Nanomaterials

2.1. Cellulose Nanocrystals (CNCs)

2.2. Cellulose Nanofibrils (CNFs)

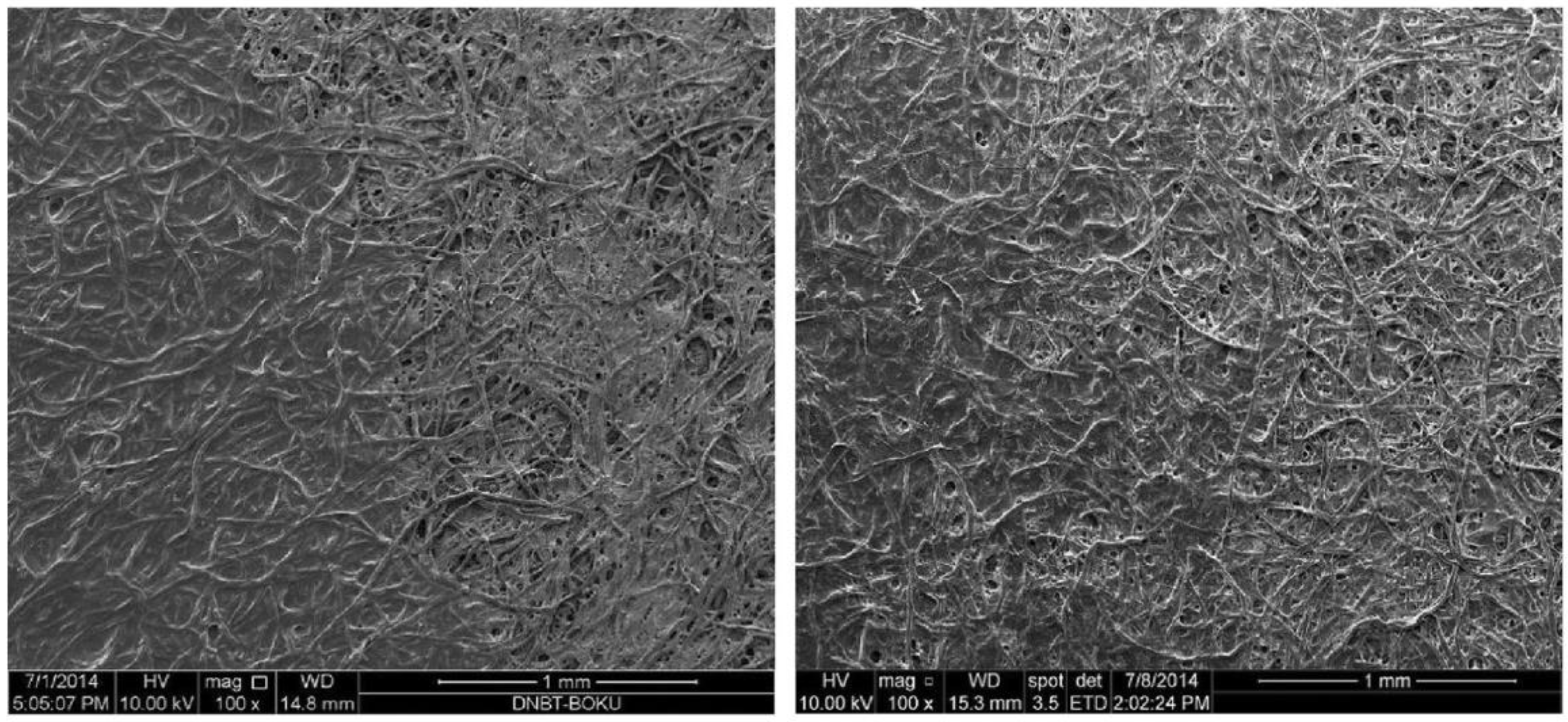

2.3. Bacterial Nanocellulose (BNC)

3. Characterization Methods of Cellulose Nanomaterials

4. Applications of Cellulose Nanomaterials in Cultural Heritage

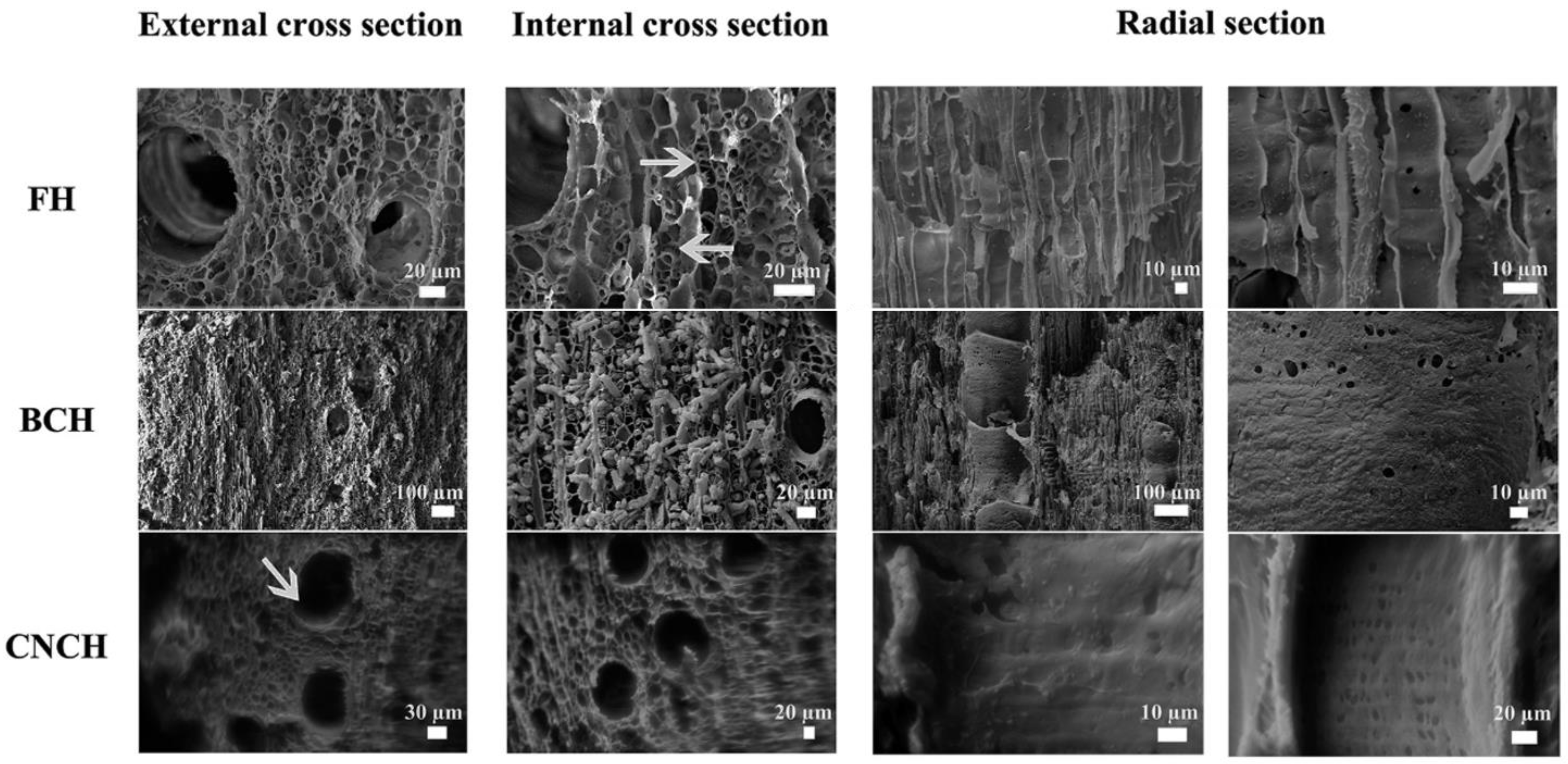

4.1. Wood

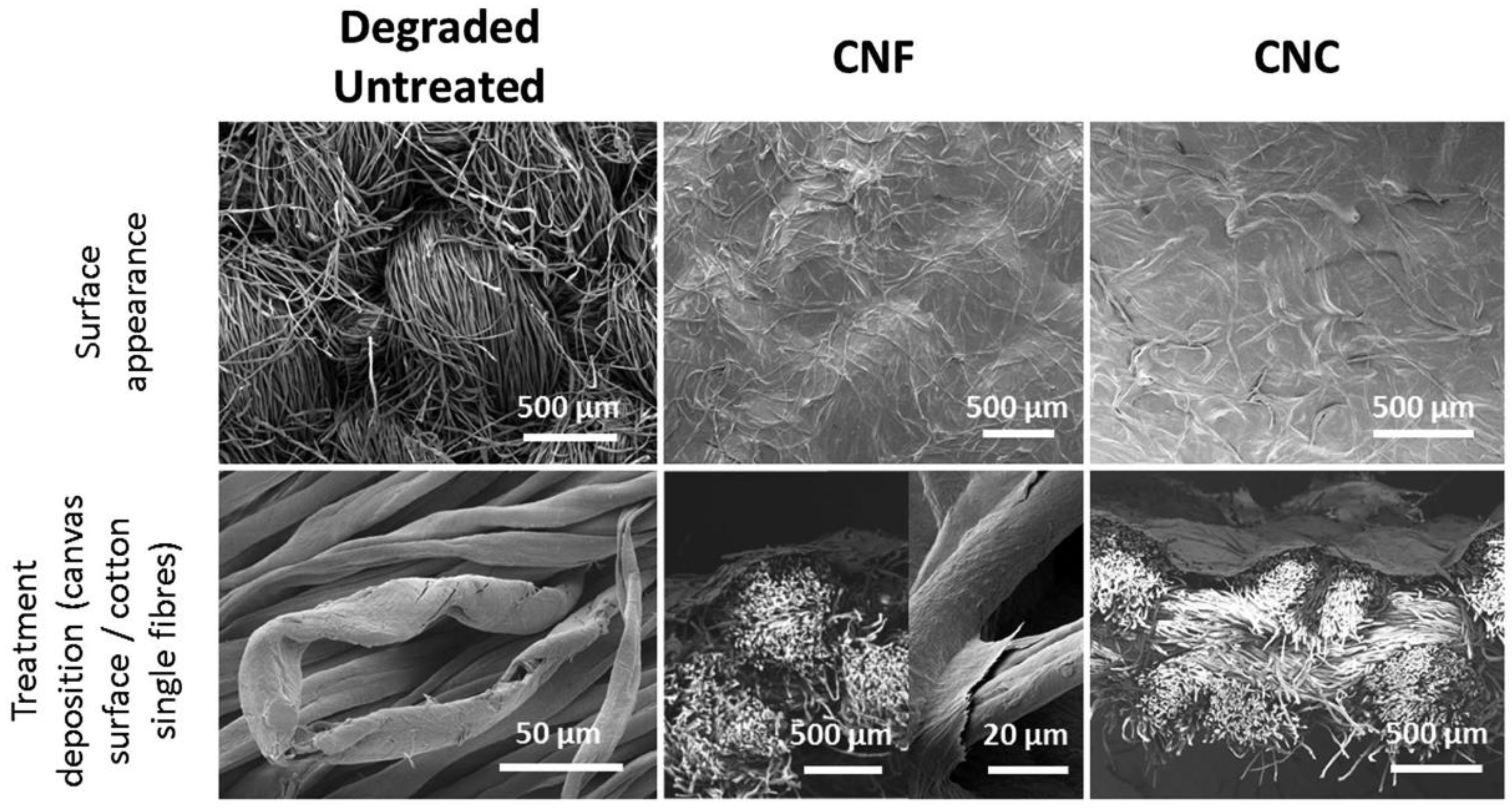

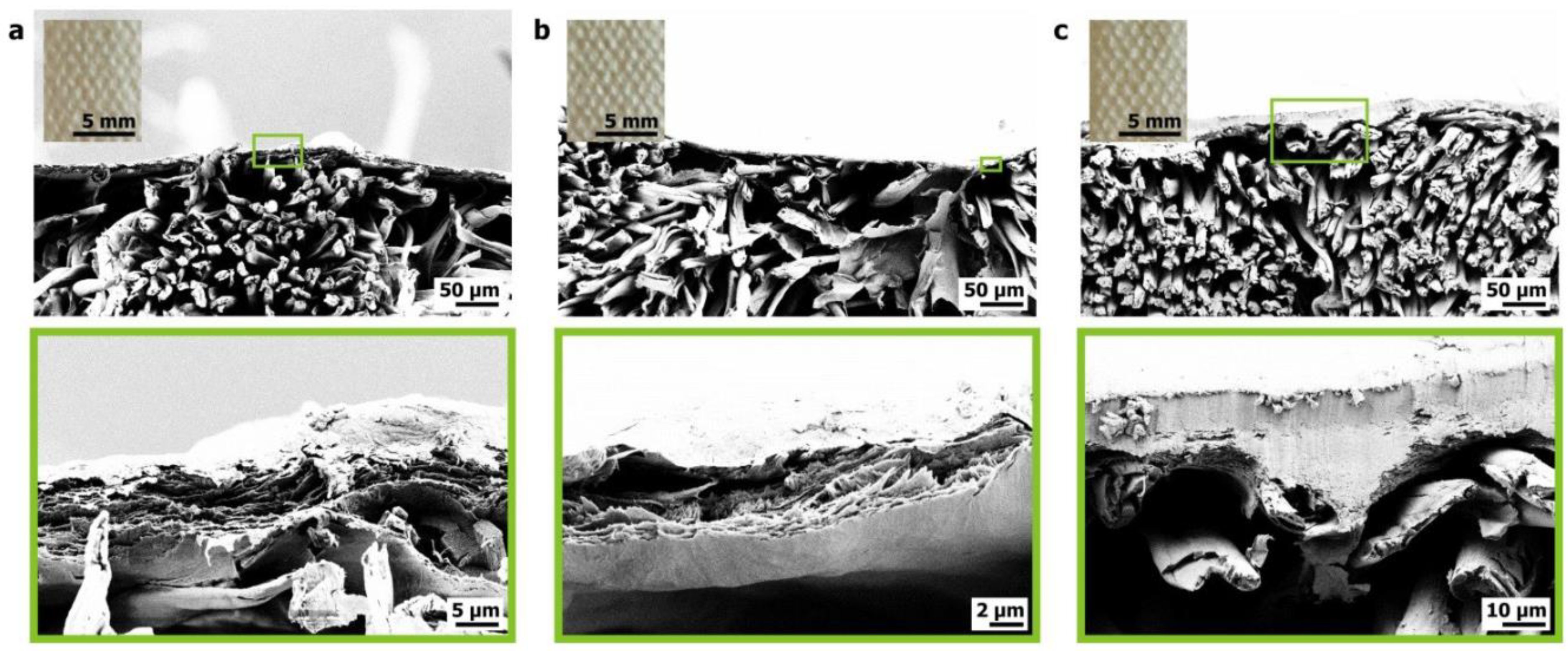

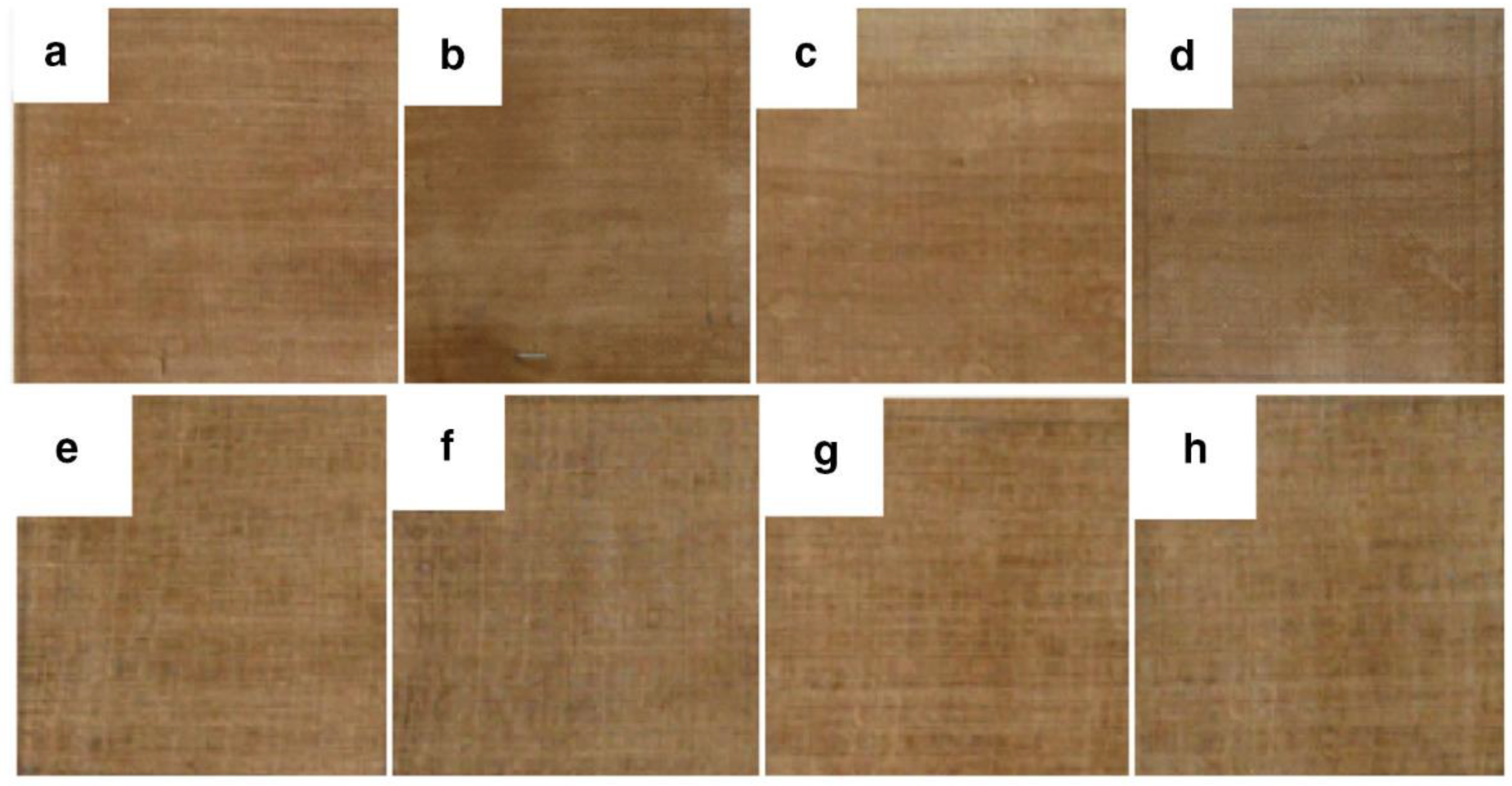

4.2. Painting Canvases

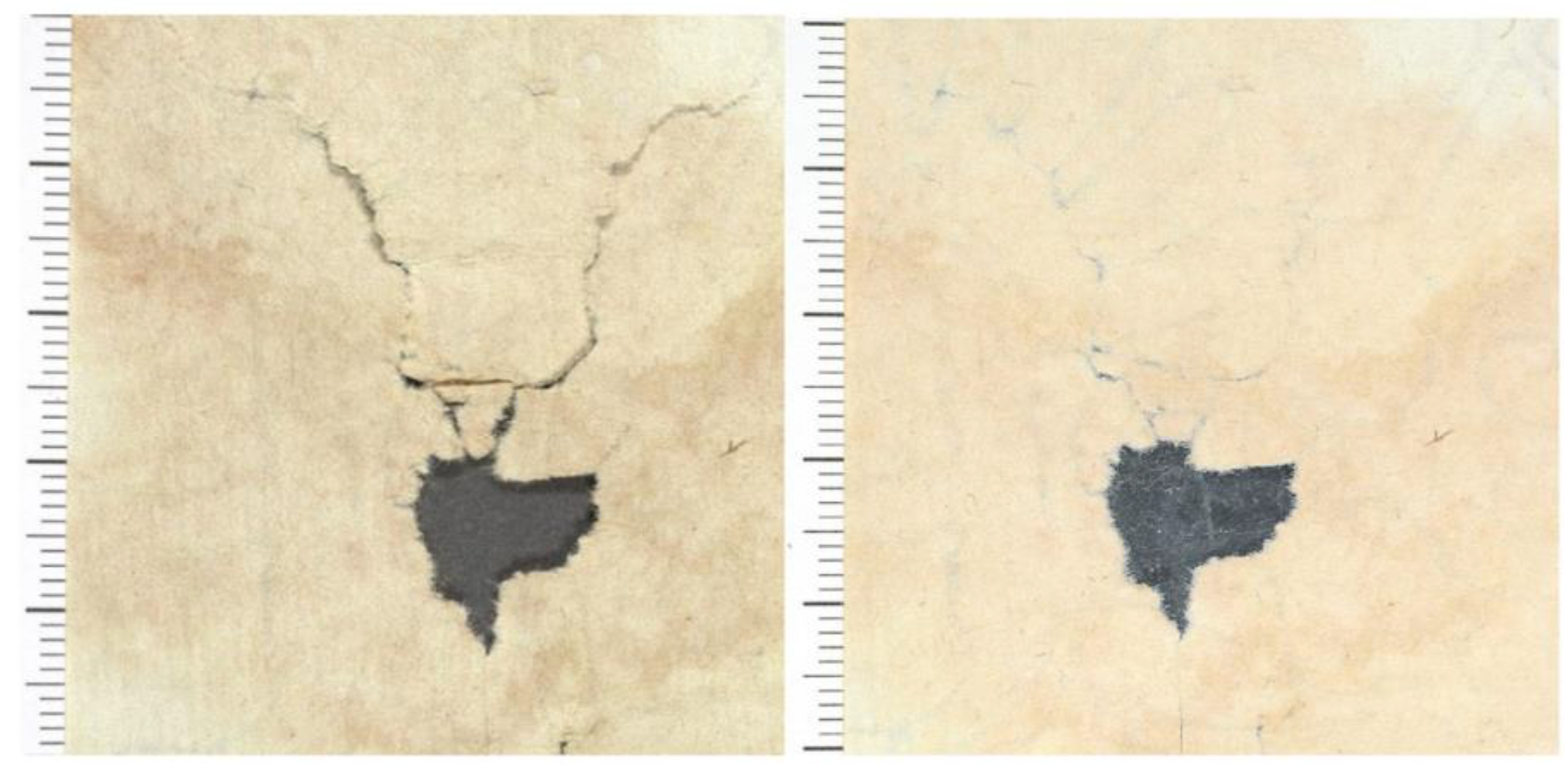

4.3. Historical Papers

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

- Vocabulary Section

References

- Tortora, L.; Di Carlo, G.; Mosquera, M.J.; Ingo, G.M. Editorial: Nanoscience and Nanomaterials for the Knowledge and Conservation of Cultural Heritage. Front. Mater. 2020, 7, 606076. [Google Scholar] [CrossRef]

- Louis, A.C.F.; Venkatachalam, S. Energy Efficient Process for Valorization of Corn Cob as a Source for Nanocrystalline Cellulose and Hemicellulose Production. Int. J. Biol. Macromol. 2020, 163, 260–269. [Google Scholar] [CrossRef] [PubMed]

- Mateo, S.; Peinado, S.; Morillas-Gutiérrez, F.; La Rubia, M.D.; Moya, A.J. Nanocellulose from Agricultural Wastes: Products and Applications—A Review. Processes 2021, 9, 1594. [Google Scholar] [CrossRef]

- Baglioni, P.; Chelazzi, D.; Giorgi, R. Nanotechnologies in the Conservation of Cultural Heritage; Springer: Dordrecht, The Netherlands, 2015; ISBN 978-94-017-9302-5. [Google Scholar]

- Rajinipriya, M.; Nagalakshmaiah, M.; Robert, M.; Elkoun, S. Importance of Agricultural and Industrial Waste in the Field of Nanocellulose and Recent Industrial Developments of Wood Based Nanocellulose: A Review. ACS Sustain. Chem. Eng. 2018, 6, 2807–2828. [Google Scholar] [CrossRef]

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392. [Google Scholar] [CrossRef] [PubMed]

- Mishra, R.K.; Sabu, A.; Tiwari, S.K. Materials Chemistry and the Futurist Eco-Friendly Applications of Nanocellulose: Status and Prospect. J. Saudi Chem. Soc. 2018, 22, 949–978. [Google Scholar] [CrossRef]

- Gupta, G.K.; Shukla, P. Lignocellulosic Biomass for the Synthesis of Nanocellulose and Its Eco-Friendly Advanced Applications. Front. Chem. 2020, 8, 601256. [Google Scholar] [CrossRef] [PubMed]

- Mali, P.; Sherje, A.P. Cellulose Nanocrystals: Fundamentals and Biomedical Applications. Carbohydr. Polym. 2022, 275, 118668. [Google Scholar] [CrossRef]

- Kumar, R.; Rai, B.; Gahlyan, S.; Kumar, G. A Comprehensive Review on Production, Surface Modification and Characterization of Nanocellulose Derived from Biomass and Its Commercial Applications. Express Polym. Lett. 2021, 15, 104–120. [Google Scholar] [CrossRef]

- Mendoza, D.J.; Browne, C.; Raghuwanshi, V.S.; Mouterde, L.M.M.; Simon, G.P.; Allais, F.; Garnier, G. Phenolic Ester-Decorated Cellulose Nanocrystals as UV-Absorbing Nanoreinforcements in Polyvinyl Alcohol Films. ACS Sustain. Chem. Eng. 2021, 9, 6427–6437. [Google Scholar] [CrossRef]

- Du, W.; Ge, X.; Huang, H.; Zhang, T.; Zhang, Z.; Shang, X. Fabrication of High Transparent, Mechanical Strong, and Flame Retardant Waterborne Polyurethane Composites by Incorporating Phosphorus-silicon Functionalized Cellulose Nanocrystals. J. Appl. Polym. Sci. 2022, 139, 51496. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Rahimian Koloor, S.S.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Gao, Z.Y.; Su, X.P.; Chen, X.; Jiang, L.; Yao, J.M. Adsorption Removal of Dyes from Single and Binary Solutions Using a Cellulose-Based Bioadsorbent. ACS Sustain. Chem. Eng. 2015, 3, 432–442. [Google Scholar] [CrossRef]

- Spagnuolo, L.; D’Orsi, R.; Operamolla, A. Nanocellulose for Paper and Textile Coating: The Importance of Surface Chemistry. ChemPlusChem 2022, 87, e202200204. [Google Scholar] [CrossRef] [PubMed]

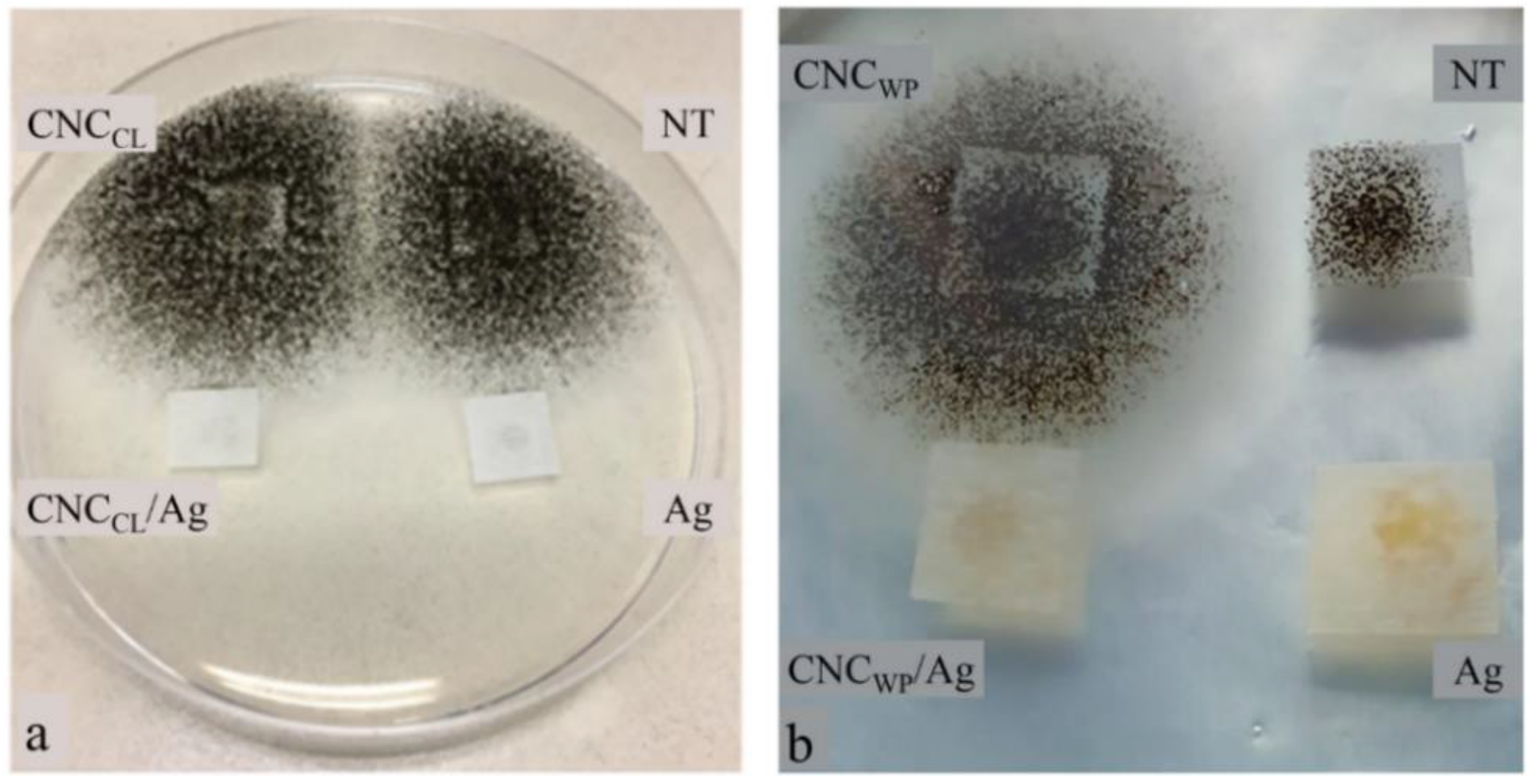

- Bergamonti, L.; Potenza, M.; Haghighi Poshtiri, A.; Lorenzi, A.; Sanangelantoni, A.M.; Lazzarini, L.; Lottici, P.P.; Graiff, C. Ag-Functionalized Nanocrystalline Cellulose for Paper Preservation and Strengthening. Carbohydr. Polym. 2020, 231, 115773. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, X.; Weng, J.; Zhang, J.; Zhang, M. Protective Coating of Paper Works: ZnO/Cellulose Nanocrystal Composites and Analytical Characterization. J. Cult. Herit. 2019, 38, 64–74. [Google Scholar] [CrossRef]

- Antonelli, F.; Galotta, G.; Sidoti, G.; Zikeli, F.; Nisi, R.; Davidde Petriaggi, B.; Romagnoli, M. Cellulose and Lignin Nano-Scale Consolidants for Waterlogged Archaeological Wood. Front. Chem. 2020, 8, 32. [Google Scholar] [CrossRef]

- Bridarolli, A.; Nechyporchuk, O.; Odlyha, M.; Oriola, M.; Bordes, R.; Holmberg, K.; Anders, M.; Chevalier, A.; Bozec, L. Nanocellulose-Based Materials for the Reinforcement of Modern Canvas-Supported Paintings. Stud. Conserv. 2018, 63, 332–334. [Google Scholar] [CrossRef]

- Owoyokun, T.; Pérez Berumen, C.M.; Martínez Luévanos, A.; Cantú, L.; Ceniceros, A.C.L. Cellulose Nanocrystals: Obtaining and Sources of a Promising Bionanomaterial for Advanced Applications. Biointerface Res. Appl. Chem. 2020, 11, 11797–11816. [Google Scholar] [CrossRef]

- Hamed, S.A.A.K.M.; Hassan, M.L. A New Mixture of Hydroxypropyl Cellulose and Nanocellulose for Wood Consolidation. J. Cult. Herit. 2019, 35, 140–144. [Google Scholar] [CrossRef]

- Morais Júnior, R.R.; Cardoso, G.V.; Ferreira, E.S.; Costa, H.L. Surface Characterization, Mechanical and Abrasion Resistance of Nanocellulose-Reinforced Wood Panels. Surf. Topogr. Metrol. Prop. 2020, 8, 025011. [Google Scholar] [CrossRef]

- Nechyporchuk, O. On the Potential of Using Nanocellulose for Consolidation of Painting Canvases. Carbohydr. Polym. 2018, 194, 161–169. [Google Scholar] [CrossRef]

- Böhme, N.; Anders, M.; Reichelt, T.; Schuhmann, K.; Bridarolli, A.; Chevalier, A. New Treatments for Canvas Consolidation and Conservation. Herit. Sci. 2020, 8, 16. [Google Scholar] [CrossRef]

- Oriola-Folch, M.; Campo-Francés, G.; Nualart-Torroja, A.; Ruiz-Recasens, C.; Bautista-Morenilla, I. Novel Nanomaterials to Stabilise the Canvas Support of Paintings Assessed from a Conservator’s Point of View. Herit. Sci. 2020, 8, 23. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H. Recent Advances in Nanocellulose-Based Different Biomaterials: Types, Properties, and Emerging Applications. J. Mater. Res. Technol. 2021, 14, 2601–2623. [Google Scholar] [CrossRef]

- Huang, J.; Dufresne, A.; Lin, N. Nanocellulose from Fundamentals to Advanced Materials, 10th ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2019; ISBN 978-3-527-34269-3. [Google Scholar]

- Mishra, D.; Shanker, K.; Khare, P. Nanocellulose-Mediated Fabrication of Sustainable Future Materials. In Sustainable Nanocellulose and Nanohydrogels from Natural Sources; Elsevier: Amsterdam, The Netherlands, 2020; pp. 217–236. ISBN 978-0-12-816789-2. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S.; Atikah, M.S.N. Nanocellulose Reinforced Starch Polymer Composite: A Review of Preparation, Properties and Application. In Proceedings of the 5th International Conference on Applied Sciences and Engineering (ICASEA, 2018), Capthorne Hotel, Cameron Highlands, Malaysia, 7 April 2018; p. 17. [Google Scholar]

- Wei, L.; Agarwal, U.P.; Hirth, K.C.; Matuana, L.M.; Sabo, R.C.; Stark, N.M. Chemical Modification of Nanocellulose with Canola Oil Fatty Acid Methyl Ester. Carbohydr. Polym. 2017, 169, 108–116. [Google Scholar] [CrossRef]

- Kumar, R.; Kumari, S.; Rai, B.; Das, R.; Kumar, G. Effect of Nano-Cellulosic Fiber on Mechanical and Barrier Properties of Polylactic Acid (PLA) Green Nanocomposite Film. Mater. Res. Express 2019, 6, 125108. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose Processing Properties and Potential Applications. Curr. For. Rep. 2019, 5, 76–89. [Google Scholar] [CrossRef]

- Kumar, A.; Singh Negi, Y.; Choudhary, V.; Kant Bhardwaj, N. Characterization of Cellulose Nanocrystals Produced by Acid-Hydrolysis from Sugarcane Bagasse as Agro-Waste. J. Mater. Phys. Chem. 2020, 2, 1–8. [Google Scholar] [CrossRef]

- Farooq, A.; Jiang, S.; Farooq, A.; Naeem, M.A.; Ahmad, A.; Liu, L. Structure and Properties of High Quality Natural Cellulose Nano Fibrils from a Novel Material Ficus Natalensis Barkcloth. J. Ind. Text. 2019, 152808371988753. [Google Scholar] [CrossRef]

- Michelin, M.; Gomes, D.G.; Romaní, A.; Polizeli, M.D.L.T.M.; Teixeira, J.A. Nanocellulose Production: Exploring the Enzymatic Route and Residues of Pulp and Paper Industry. Molecules 2020, 25, 3411. [Google Scholar] [CrossRef]

- Nagarajan, K.J.; Ramanujam, N.R.; Sanjay, M.R.; Siengchin, S.; Surya Rajan, B.; Sathick Basha, K.; Madhu, P.; Raghav, G.R. A Comprehensive Review on Cellulose Nanocrystals and Cellulose Nanofibers: Pretreatment, Preparation, and Characterization. Polym. Compos. 2021, 42, 1588–1630. [Google Scholar] [CrossRef]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and Crop Wastes: A New Source for Nanocellulose Biorefinery. Ind. Crops Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Abdullah, N.A.; Rani, M.S.A.; Mohammad, M.; Sainorudin, M.H.; Asim, N.; Yaakob, Z.; Razali, H.; Emdadi, Z. Nanocellulose from Agricultural Waste as an Emerging Material for Nanotechnology Applications—An Overview. Polimery 2021, 66, 157–168. [Google Scholar] [CrossRef]

- Thomas, P.; Duolikun, T.; Rumjit, N.P.; Moosavi, S.; Lai, C.W.; Bin Johan, M.R.; Fen, L.B. Comprehensive Review on Nanocellulose: Recent Developments, Challenges and Future Prospects. J. Mech. Behav. Biomed. Mater. 2020, 110, 103884. [Google Scholar] [CrossRef]

- Hussain, Z.; Sajjad, W.; Khan, T.; Wahid, F. Production of Bacterial Cellulose from Industrial Wastes: A Review. Cellulose 2019, 26, 2895–2911. [Google Scholar] [CrossRef]

- Adriaens, A. European Actions to Promote and Coordinate the Use of Analytical Techniques for Cultural Heritage Studies. TrAC Trends Anal. Chem. 2004, 23, 583–586. [Google Scholar] [CrossRef]

- Balea, A.; Blanco, A.; Delgado-Aguilar, M.; Monte, M.C.; Tarrés, Q.; Fuente, E.; Mutjé, P.; Negro, C. Nanocellulose Characterization Challenges. BioResources 2021, 16, 4382–4410. [Google Scholar] [CrossRef]

- Zhao, C.; Zhang, Y.; Wang, C.-C.; Hou, M.; Li, A. Recent Progress in Instrumental Techniques for Architectural Heritage Materials. Herit. Sci. 2019, 7, 36. [Google Scholar] [CrossRef]

- Kargarzadeh, K.; Ahmad, I.; Thomas, S.; Dufresne, A. Handbook of Nanocellulose and Cellulose Nanocomposites; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2017; Volume 1, ISBN 978-3-527-68999-6. [Google Scholar]

- Kargarzadeh, H.; Ahmad, I.; Thomas, S.; Dufresne, A. Handbook of Nanocellulose and Cellulose Nanocomposites; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2017; Volume 2, ISBN 978-3-527-68999-6. [Google Scholar]

- Huntley, C.J.; Crews, K.D.; Abdalla, M.A.; Russell, A.E.; Curry, M.L. Influence of Strong Acid Hydrolysis Processing on the Thermal Stability and Crystallinity of Cellulose Isolated from Wheat Straw. Int. J. Chem. Eng. 2015, 2015, 658163. [Google Scholar] [CrossRef]

- Cataldi, A.; Esposito Corcione, C.; Frigione, M.; Pegoretti, A. Photocurable Resin/Nanocellulose Composite Coatings for Wood Protection. Prog. Org. Coat. 2017, 106, 128–136. [Google Scholar] [CrossRef]

- Huang, C.; Yu, H.; Abdalkarim, S.Y.H.; Li, Y.; Chen, X.; Yang, X.; Zhou, Y.; Zhang, L. A Comprehensive Investigation on Cellulose Nanocrystals with Different Crystal Structures from Cotton via an Efficient Route. Carbohydr. Polym. 2022, 276, 118766. [Google Scholar] [CrossRef] [PubMed]

- Gond, R.K.; Gupta, M.K.; Jawaid, M. Extraction of Nanocellulose from Sugarcane Bagasse and Its Characterization for Potential Applications. Polym. Compos. 2021, 42, 5400–5412. [Google Scholar] [CrossRef]

- Singh, H.K.; Patil, T.; Vineeth, S.K.; Das, S.; Pramanik, A.; Mhaske, S.T. Isolation of Microcrystalline Cellulose from Corn Stover with Emphasis on Its Constituents: Corn Cover and Corn Cob. Mater. Today Proc. 2020, 27, 589–594. [Google Scholar] [CrossRef]

- Morán, J.I.; Vázquez, A.; Cyras, V.P. Bio-Nanocomposites Based on Derivatized Potato Starch and Cellulose, Preparation and Characterization. J. Mater. Sci. 2013, 48, 7196–7203. [Google Scholar] [CrossRef]

- Camargos, C.H.M.; Poggi, G.; Chelazzi, D.; Baglioni, P.; Rezende, C.A. Protective Coatings Based on Cellulose Nanofibrils, Cellulose Nanocrystals, and Lignin Nanoparticles for the Conservation of Cellulosic Artifacts. ACS Appl. Nano Mater. 2022, 5, 13245–13259. [Google Scholar] [CrossRef]

- de Moraes, A.C.M.; Andrade, P.F.; de Faria, A.F.; Simões, M.B.; Salomão, F.C.C.S.; Barros, E.B.; Gonçalves, M.D.C.; Alves, O.L. Fabrication of Transparent and Ultraviolet Shielding Composite Films Based on Graphene Oxide and Cellulose Acetate. Carbohydr. Polym. 2015, 123, 217–227. [Google Scholar] [CrossRef]

- Franco-Castillo, I.; Hierro, L.; de la Fuente, J.M.; Seral-Ascaso, A.; Mitchell, S.G. Perspectives for Antimicrobial Nanomaterials in Cultural Heritage Conservation. Chem 2021, 7, 629–669. [Google Scholar] [CrossRef]

- Roman, M. Toxicity of Cellulose Nanocrystals: A Review. Ind. Biotechnol. 2015, 11, 25–33. [Google Scholar] [CrossRef]

- Ramesh, S.; Radhakrishnan, P. Cellulose Nanoparticles from Agro-Industrial Waste for the Development of Active Packaging. Appl. Surf. Sci. 2019, 484, 1274–1281. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, C.; Qi, H.; Hubbe, M.A. Some Challenges in the Naming and Measuring of Nanocellulose. BioResources 2021, 16, 4671–4674. [Google Scholar] [CrossRef]

- Barbash, V.A.; Yashchenko, O.V.; Gondovska, A.S.; Deykun, I.M. Preparation and Characterization of Nanocellulose Obtained by TEMPO-Mediated Oxidation of Organosolv Pulp from Reed Stalks. Appl. Nanosci. 2022, 12, 835–848. [Google Scholar] [CrossRef]

- Operamolla, A.; Mazzuca, C.; Capodieci, L.; Di Benedetto, F.; Severini, L.; Titubante, M.; Martinelli, A.; Castelvetro, V.; Micheli, L. Toward a Reversible Consolidation of Paper Materials Using Cellulose Nanocrystals. ACS Appl. Mater. Interfaces 2021, 13, 44972–44982. [Google Scholar] [CrossRef] [PubMed]

- Basile, R.; Bergamonti, L.; Fernandez, F.; Graiff, C.; Haghighi, A.; Isca, C.; Lottici, P.P.; Pizzo, B.; Predieri, G. Bio-Inspired Consolidants Derived from Crystalline Nanocellulose for Decayed Wood. Carbohydr. Polym. 2018, 202, 164–171. [Google Scholar] [CrossRef]

- Palladino, N.; Hacke, M.; Poggi, G.; Nechyporchuk, O.; Kolman, K.; Xu, Q.; Persson, M.; Giorgi, R.; Holmberg, K.; Baglioni, P.; et al. Nanomaterials for Combined Stabilisation and Deacidification of Cellulosic Materials—The Case of Iron-Tannate Dyed Cotton. Nanomaterials 2020, 10, 900. [Google Scholar] [CrossRef]

- Varshney, S.; Mishra, N.; Gupta, M.K. Progress in Nanocellulose and Its Polymer Based Composites: A Review on Processing, Characterization, and Applications. Polym. Compos. 2021, 42, 3660–3686. [Google Scholar] [CrossRef]

- Brunelli, A.; Calgaro, L.; Semenzin, E.; Cazzagon, V.; Giubilato, E.; Marcomini, A.; Badetti, E. Leaching of Nanoparticles from Nano-Enabled Products for the Protection of Cultural Heritage Surfaces: A Review. Environ. Sci. Eur. 2021, 33, 48. [Google Scholar] [CrossRef]

- Ion, R.-M.; Doncea, S.-M.; Ţurcanu-Caruțiu, D. Nanotechnologies in Cultural Heritage—Materials and Instruments for Diagnosis and Treatment. In Novel Nanomaterials—Synthesis and Applications; Kyzas, G.Z., Mitropoulos, A.C., Eds.; InTech: Vienna, Austria, 2018; ISBN 978-1-78923-088-8. [Google Scholar]

- Semenzin, E.; Giubilato, E.; Badetti, E.; Picone, M.; Volpi Ghirardini, A.; Hristozov, D.; Brunelli, A.; Marcomini, A. Guiding the Development of Sustainable Nano-Enabled Products for the Conservation of Works of Art: Proposal for a Framework Implementing the Safe by Design Concept. Environ. Sci. Pollut. Res. 2019, 26, 26146–26158. [Google Scholar] [CrossRef]

- Vineeth, S.K.; Gadhave, R.V.; Gadekar, P.T. Chemical Modification of Nanocellulose in Wood Adhesive: Review. Open J. Polym. Chem. 2019, 9, 86–99. [Google Scholar] [CrossRef]

- Bridarolli, A.; Odlyha, M.; Burca, G.; Duncan, J.C.; Akeroyd, F.A.; Church, A.; Bozec, L. Controlled Environment Neutron Radiography of Moisture Sorption/Desorption in Nanocellulose-Treated Cotton Painting Canvases. ACS Appl. Polym. Mater. 2021, 3, 777–788. [Google Scholar] [CrossRef]

- Imchalee, N.; Meesupthong, R.; Torgbo, S.; Sukyai, P. Cellulose Nanocrystals as Sustainable Material for Enhanced Painting Efficiency of Watercolor Paint. Surf. Interfaces 2021, 27, 101570. [Google Scholar] [CrossRef]

- Harandi, D.; González-Benito, J.; Olmos, D. Consolidation of Fir Wood by Poly(Vinyl Butyral-Co-Vinyl Alcohol-Co-Vinyl Acetate) Treatment: Study of Surface and Mechanical Characteristics. Polymers 2020, 12, 1039. [Google Scholar] [CrossRef]

- Wang, Y.; Schniewind, A.P. Consolidation of Deteriorated Wood with Soluble Resins. J. Am. Inst. Conserv. 1985, 24, 77–91. [Google Scholar] [CrossRef]

- Moise, V.; Stanculescu, I.; Vasilca, S.; Cutrubinis, M.; Pincu, E.; Oancea, P.; Raducan, A.; Meltzer, V. Consolidation of Very Degraded Cultural Heritage Wood Artefacts Using Radiation Curing of Polyester Resins. Radiat. Phys. Chem. 2019, 156, 314–319. [Google Scholar] [CrossRef]

- Tsetsekou, E.; Platanianaki, A.; Pournou, A. Assessing Wood Adhesives Used in Conservation by Testing Their Bond Strength and Ageing Behavior. Procedia Struct. Integr. 2018, 10, 227–234. [Google Scholar] [CrossRef]

- Dastjerdi, Z.; Cranston, E.D.; Dubé, M.A. Pressure Sensitive Adhesive Property Modification Using Cellulose Nanocrystals. Int. J. Adhes. Adhes. 2018, 81, 36–42. [Google Scholar] [CrossRef]

- Inamuddin; Thomas, S.; Kumar Mishra, R.; Asiri, A.M. Sustainable Polymer Composites and Nanocomposites; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-05398-7. [Google Scholar]

- Jiang, W.; Tomppo, L.; Pakarinen, T.; Sirviö, J.A.; Liimatainen, H.; Haapala, A.T. Effect of Cellulose Nanofibrils on the Bond Strength of Polyvinyl Acetate and Starch Adhesives for Wood. BioResources 2018, 13, 2283–2292. [Google Scholar] [CrossRef]

- Vardanyan, V.; Galstian, T.; Riedl, B. Effect of Addition of Cellulose Nanocrystals to Wood Coatings on Color Changes and Surface Roughness Due to Accelerated Weathering. J. Coat. Technol. Res. 2015, 12, 247–258. [Google Scholar] [CrossRef]

- Broda, M.; Hill, C.A.S. Conservation of Waterlogged Wood—Past, Present and Future Perspectives. Forests 2021, 12, 1193. [Google Scholar] [CrossRef]

- Pedersen, N.B.; Łucejko, J.J.; Modugno, F.; Björdal, C. Correlation between Bacterial Decay and Chemical Changes in Waterlogged Archaeological Wood Analysed by Light Microscopy and Py-GC/MS. Holzforschung 2021, 75, 635–645. [Google Scholar] [CrossRef]

- Braovac, S.; Kutzke, H. The Presence of Sulfuric Acid in Alum-Conserved Wood—Origin and Consequences. J. Cult. Herit. 2012, 13, S203–S208. [Google Scholar] [CrossRef]

- Hocker, E.; Almkvist, G.; Sahlstedt, M. The Vasa Experience with Polyethylene Glycol: A Conservator’s Perspective. J. Cult. Herit. 2012, 13, S175–S182. [Google Scholar] [CrossRef]

- Cavallaro, G.; Lazzara, G.; Milioto, S.; Parisi, F.; Ruisi, F. Nanocomposites Based on Esterified Colophony and Halloysite Clay Nanotubes as Consolidants for Waterlogged Archaeological Woods. Cellulose 2017, 24, 3367–3376. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, L.; Zhang, B.; Hu, Y. A Comparative Study of Reinforcement Materials for Waterlogged Wood Relics in Laboratory. J. Cult. Herit. 2019, 36, 94–102. [Google Scholar] [CrossRef]

- Bridarolli, A. Multiscale Approach in the Assessment of Nanocellulose-Based Materials As Consolidants for Painting Canvases. Ph.D. Thesis, University College London, Gower Street, London, UK, 2019. [Google Scholar]

- Hackney, S.; Hedley, G. Measurements of the Ageing of Linen Canvas. Stud. Conserv. 1981, 26, 1–14. [Google Scholar] [CrossRef]

- Hendrickx, R.; Desmarais, G.; Weder, M.; Ferreira, E.S.B.; Derome, D. Moisture Uptake and Permeability of Canvas Paintings and Their Components. J. Cult. Herit. 2016, 19, 445–453. [Google Scholar] [CrossRef]

- Poyatos, F.; Morales, F.; Nicholson, A.W.; Giordano, A. Physiology of Biodeterioration on Canvas Paintings. J. Cell. Physiol. 2018, 233, 2741–2751. [Google Scholar] [CrossRef]

- Kolman, K.; Nechyporchuk, O.; Persson, M.; Holmberg, K.; Bordes, R. Combined Nanocellulose/Nanosilica Approach for Multiscale Consolidation of Painting Canvases. ACS Appl. Nano Mater. 2018, 1, 2036–2040. [Google Scholar] [CrossRef]

- Kolman, K.; Nechyporchuk, O.; Persson, M.; Holmberg, K.; Bordes, R. Preparation of Silica/Polyelectrolyte Complexes for Textile Strengthening Applied to Painting Canvas Restoration. Colloids Surf. Physicochem. Eng. Asp. 2017, 532, 420–427. [Google Scholar] [CrossRef]

- Völkel, L.; Ahn, K.; Hähner, U.; Gindl-Altmutter, W.; Potthast, A. Nano Meets the Sheet: Adhesive-Free Application of Nanocellulosic Suspensions in Paper Conservation. Herit. Sci. 2017, 5, 23. [Google Scholar] [CrossRef]

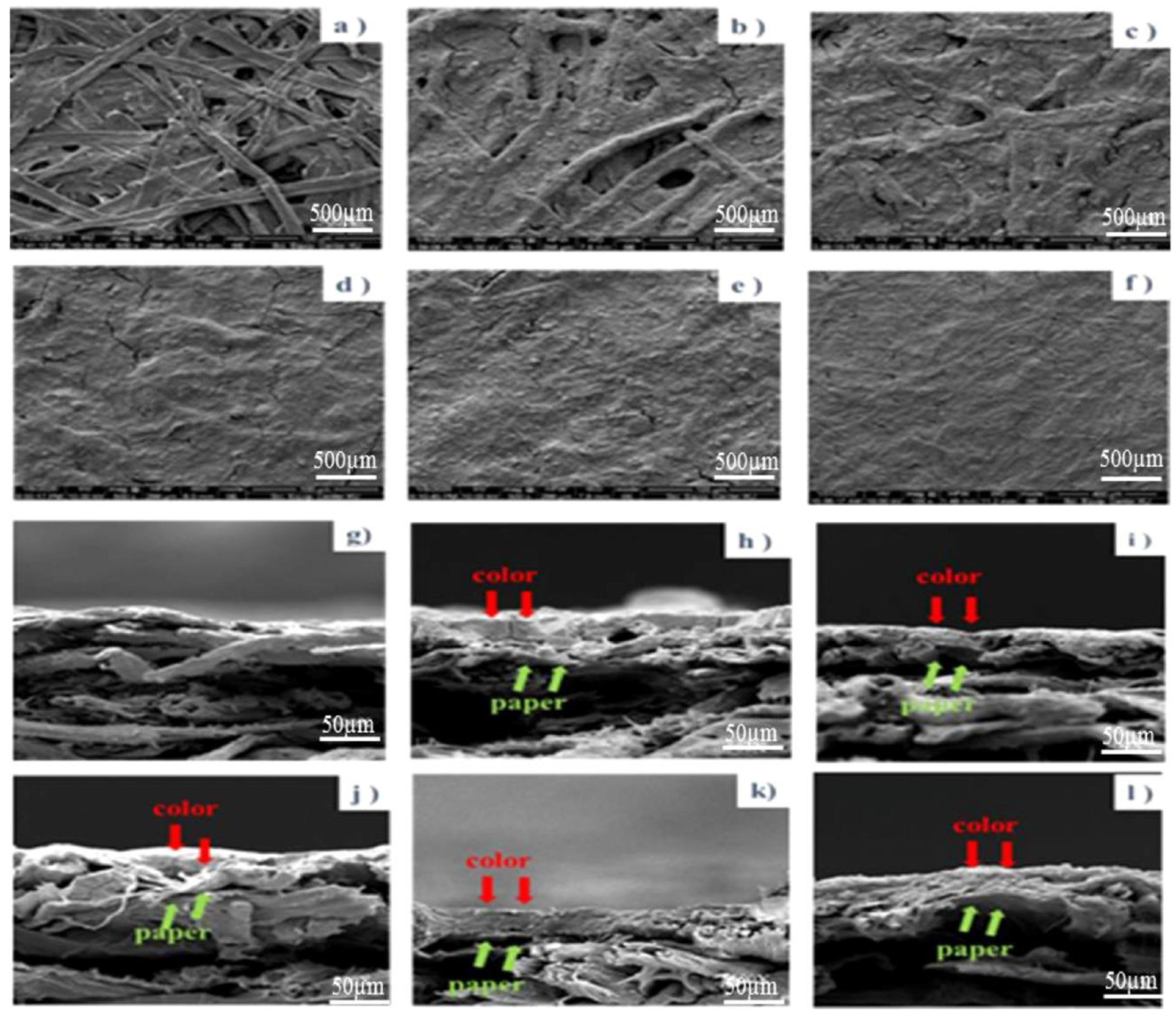

- Liu, J.; Xing, H.; Wang, J.; Cao, J.; Chao, X.; Jia, Z.; Li, Y. A New Reinforcement Method for the Conservation of Fragile, Double-Sided, Printed Paper Cultural Relics. Herit. Sci. 2021, 9, 123. [Google Scholar] [CrossRef]

- Wang, Z.; Cheng, C.; Cheng, Y.; Zheng, L.; Hu, D. Quaternary Alloy Quantum Dots as Fluorescence Probes for Total Acidity Detection of Paper-Based Relics. Nanomaterials 2021, 11, 1726. [Google Scholar] [CrossRef]

- Ma, X.; Tian, S.; Li, X.; Fan, H.; Fu, S. Combined Polyhexamethylene Guanidine and Nanocellulose for the Conservation and Enhancement of Ancient Paper. Cellulose 2021, 28, 8027–8042. [Google Scholar] [CrossRef]

- Piovesan, C.; Fabre-Francke, I.; Paris-Lacombe, S.; Dupont, A.-L.; Fichet, O. Strengthening Naturally and Artificially Aged Paper Using Polyaminoalkylalkoxysilane Copolymer Networks. Cellulose 2018, 25, 6071–6082. [Google Scholar] [CrossRef]

- Perdoch, W.; Cao, Z.; Florczak, P.; Markiewicz, R.; Jarek, M.; Olejnik, K.; Mazela, B. Influence of Nanocellulose Structure on Paper Reinforcement. Molecules 2022, 27, 4696. [Google Scholar] [CrossRef]

- Bansa, H.; Ishii, R. The Effect of Different Strengthening Methods on Different Kinds of Paper. Restaurator 1997, 18. [Google Scholar] [CrossRef]

- Gómez, N.; Santos, S.M.; Carbajo, J.M.; Villar, J.C. Use of Bacterial Cellulose in Degraded Paper Restoration: Effect on Visual Appearance of Printed Paper. BioResources 2017, 12, 9130–9142. [Google Scholar] [CrossRef]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of Bacterial Cellulose in Degraded Paper Restoration. Part I: Application on Model Papers. J. Mater. Sci. 2016, 51, 1541–1552. [Google Scholar] [CrossRef]

- Santos, S.M.; Carbajo, J.M.; Gómez, N.; Quintana, E.; Ladero, M.; Sánchez, A.; Chinga-Carrasco, G.; Villar, J.C. Use of Bacterial Cellulose in Degraded Paper Restoration. Part II: Application on Real Samples. J. Mater. Sci. 2016, 51, 1553–1561. [Google Scholar] [CrossRef]

- Dreyfuss-Deseigne, R. Nanocellulose Films in Art Conservation: A New and Promising Mending Material for Translucent Paper Objects. J. Pap. Conserv. 2017, 18, 18–29. [Google Scholar] [CrossRef]

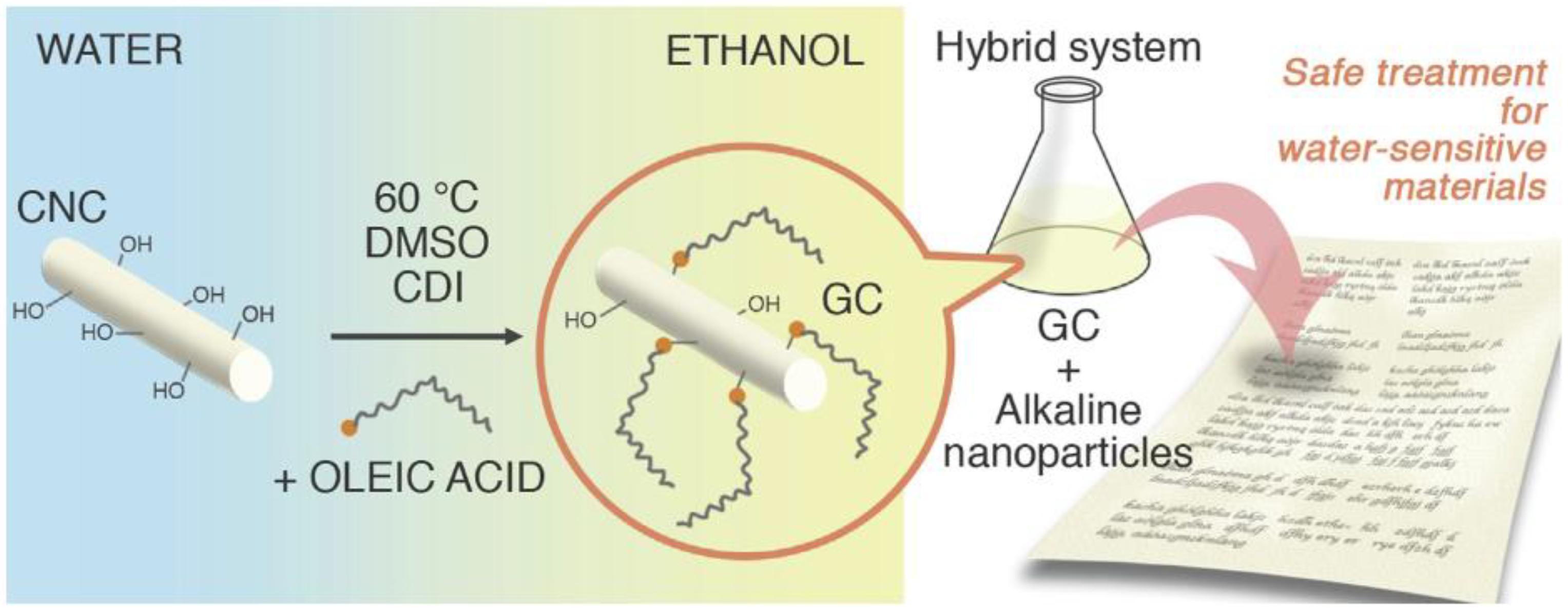

- Xu, Q.; Poggi, G.; Resta, C.; Baglioni, M.; Baglioni, P. Grafted Nanocellulose and Alkaline Nanoparticles for the Strengthening and Deacidification of Cellulosic Artworks. J. Colloid Interface Sci. 2020, 576, 147–157. [Google Scholar] [CrossRef] [PubMed]

- Konkol, N.R.; McNamara, C.J.; Hellman, E.; Mitchell, R. Early Detection of Fungal Biomass on Library Materials. J. Cult. Herit. 2012, 13, 115–119. [Google Scholar] [CrossRef]

- Çakar, P.; Akyol, E. The Effects of Natural Dye and Iron Gall Ink on Degradation Kinetics of Cellulose by Accelerated Ageing. Stud. Conserv. 2021, 67, 381–388. [Google Scholar] [CrossRef]

- Völkel, L.; Prohaska, T.; Potthast, A. Combining Phytate Treatment and Nanocellulose Stabilization for Mitigating Iron Gall Ink Damage in Historic Papers. Herit. Sci. 2020, 8, 86. [Google Scholar] [CrossRef]

| Method | Source | Remarks |

|---|---|---|

| H2SO4 hydrolysis | Bacteria | L (nm) = 100–1000; W (nm) = 10–50; Aspect ratio (L/D) = 2–100. |

| H2SO4 hydrolysis | Valonia | L (nm) = 1000–2000; W (nm) = 10–20; Aspect ratio (L/D) = 50–200. |

| H2SO4 hydrolysis | Ramie | L (nm) = 70–200; W (nm) = 5–15; Aspect ratio (L/D) = ~12. |

| H2SO4 hydrolysis | Wood | L (nm) = 100–300; W (nm) = 3–5; Aspect ratio (L/D) = 20–100. |

| H2SO4 hydrolysis | Sisal | L (nm) = 100–300; W (nm) = 3–5; Aspect ratio (L/D) = ~60. |

| H2SO4 hydrolysis | Tunicates | L (nm) = >1000; W (nm) = 10–20; Aspect ratio (L/D) = ~100. |

| HCl hydrolysis | Bacteria | L (nm) = 160–420; W (nm) = 15–25; Aspect ratio (L/D) = 7–23. |

| HCl hydrolysis | Cotton | L (nm) = 100–300; W (nm) = 3–5; Aspect ratio (L/D) = 20–100. |

| Cellulose Nanocrystals (CNCs) | Cellulose Nanofibrils (CNFs) | Bacterial Nanocellulose (BNC) | |

|---|---|---|---|

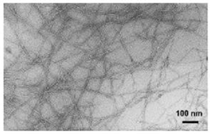

| Images |  Transmission electron microscope (100 nm) |  Transmission electron microscope (100 nm) |  Scanning microscope (8 µm) |

| Synonyms | Crystallites, whiskers, nanowhiskers, cellulose nanocrystals, rod-like cellulose microcrystals | Microfibrillated cellulose, nanofibrils, microfibrils, cellulose, nanofibers | Biocellulose, bacterial cellulose, microbial cellulose |

| Common source | Wood, cotton, hemp, flax, rice straw, wheat straw, ramie, avicel, mcc, tunicin, algae, bacterial cellulose, pea hull fibers, branch-bark of mulberry, black spruce and eucalyptus, tunicate, valonia, kraft wood, pine and spruce, palm oil, pineapple leaf fibers, grass, swede root, chardonnay grape skins, coconut fibers, softwood wood flout, kenaf fibers, rice husk, sabdariffa fibers, wood fibers, corncob. | Pea hull, kenaf, hardwood and softwood pulp, cotton linter, cotton, cassava bagasse, sugarcane bagasse, cotton, algae (valonia), tunicate cellulose, bacterial cellulose, sugar beet pulp, wheat straw, date palm tree (rachis/leaflets), coconut husk fibers, recycled pulp, acacia pulp, banana, capimdourado, mulberry, flax, hemp, luffacylindrica, mengkuang leaves, curauna. | Low molecular weight sugar, alcohols, several bacteria species such as gluconacetobacter, agrobacterium, pseudomonas, rhizobium, and sarcin. |

| Formation process | Chemical or enzymatic treatment prior to delamination or wood pulp by mechanical pressure, acid hydrolysis | Acid hydrolysis, integration of mechanical shearing process via high pressure homogenization and enzymatic hydrolysis, TEMPO-mediated oxidation | Bacterial synthesis and cultivation in aqueous culture media present by glucose, oxygen and phosphate. |

| Average size | Diameter: 5–80 nm Length: 100–250 nm | Diameter: 5–70 nm Length: 100–250 nm (from plant); 100 nm to several micrometer (from cellulose of tunicates, algae, bacteria) | Diameter: 20–100 nm Length: 1.0–5.0 µm Different types of nanofibers networks |

| Tensile Strength | 2–6 GPa | 2–4 GPa | 200–300 MPa |

| Young’s modulus | 50–143 GPa | 15–150 GPa | 15–35 Pa |

| Crystallinity Index | 54–88% | <50% | >88% |

| Property | Characterization Techniques | Acronym | Advanced Research | Industrial Environment | Cultural Heritage [43,44,45] |

|---|---|---|---|---|---|

| Size and morphology: • Length (L) • Width (w) • Diameter • Aspect ratio (L/w) • Average particle size/size distribution | Atomic force microscopy | AFM | X | X | |

| Scanning electron microscopy | SEM | X | X | ||

| Transmission electron microscopy | TEM | X | X | ||

| Optical microscopy | OM | X | X | ||

| Fiber analyzer | X | ||||

| Fractionators | X | ||||

| Gel point (for aspect ratio) | GP | X | X | ||

| Viscosity (for aspect ratio) | X | X | |||

| Light scattering techniques: - Dynamic light scattering - Depolarized DLS | DLS DDLS | X | X | ||

| Physical properties: • Crystallinity (mainly for NCC) • Degree of polymerization (DP) • Specific surface area (SSA) • Density | Crystallinity and dimensions of cellulose crystals: - X-ray diffraction - Raman spectroscopy - Infrared spectroscopy - 13C nuclear X-ray diffraction magnetic resonance - Solid-state nuclear magnetic resonance | XRD 13C NMR ssNMR | X | X | |

| Viscosity method | X | X | |||

| Determination of SSA: - N2 adsorption, Brunauer–Emmett–Teller isotherms - Congo Red method - Small-angle X-ray scattering | BET SAXS | X | |||

| Network density (on nanopapers): - Air permeability (Vase de Mariotte, Bendsen) - Porosity (calculation from basis weight and thickness) - Transparency | X | X | X | ||

| Elemental analysis (EA) | Carbon hydrogen nitrogen elemental analysis | CHN CHNS CHNSO CHNSOX | X | ||

| Secondary ion mass spectrometry | SIMS | X | |||

| X-ray photoelectron | XPS | X | X | ||

| Auger electron spectroscopy | AES | X | |||

| Energy dispersive X-ray spectroscopy | EDS (or EDX) | X | X | ||

| Inductively coupled plasma: - Mass spectrometry - Atomic emission spectroscopy | ICP-MS ICP-AES | X | |||

| Water retention | Water retention value | WRV | X | X | |

| Fibrillation degree (for NFC) | Atomic force microscopy | AFM | X | ||

| Scanning electron microscopy | SEM | X | |||

| Transmission electron microscopy | TEM | X | |||

| Optical microscope (for low fibrillation degree) | OM | X | |||

| Mechanical fractionation by combination of sieves and membranes | X | ||||

| Field/tube flow fractionation | X | ||||

| Centrifugation | X | X | |||

| Transmittance by UV-vis spectroscopy | X | X | |||

| Turbidity | X | X | |||

| Dissolved and colloidal substances (amount and quality) | Atomic force microscopy | AFM | X | X | |

| Scanning electron microscopy | SEM | X | X | ||

| Transmission electron microscopy | TEM | X | X | ||

| Gel permeation chromatography | GPC | X | |||

| Size-exclusion chromatography | SEC | X | |||

| High-performance liquid chromatography | HPLC | X | |||

| Surface charge and chemistry: • Surface modifications • Charge determination | Surface chemically modified by adsorption: - Fourier-transform infrared spectroscopy - Elemental analysis | FTIR EA | X | X | |

| Surface chemically modified by covalent bonding: - Fourier-transform infrared spectroscopy - Solid-state nuclear magnetic resonance - X-ray photoelectron spectroscopy - Elemental analysis | FTIR ssNMR XPS EA | X | X | ||

| Inverse gas chromatography | IC | X | |||

| Conductimetric titration | X | X | |||

| Charge determination: - Cationic demand - Zeta potential | CD ZP | X | X | ||

| Rheology: • Viscosity • Yield stress • Gel point • Aspect ratio | Low shear viscosity by viscometers | X | X | ||

| Gel strength, viscoelastic properties by rheometers | X | X | |||

| Mechanical and thermal properties | Tensile testing | X | X | X | |

| Flexural testing | X | X | X | ||

| Compression testing | X | X | X | ||

| Dynamic mechanical analysis | DMA | X | X | ||

| Raman spectroscopic | X | X | |||

| Thermogravimetric analysis | TGA | X | X | X | |

| Other properties | Health characterization (i.e., eye irritation, skin irritation, genotoxicity, toxicokinetic testing, systemic testing, ecotoxicity…) | X | X | ||

| Safety characterization (i.e., deflagration index…) | X | X |

| Artistic Application Field | Advantages | Disadvantages |

|---|---|---|

| Wood |

|

|

| Painting Canvases |

|

|

| Historical Paper |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fornari, A.; Rossi, M.; Rocco, D.; Mattiello, L. A Review of Applications of Nanocellulose to Preserve and Protect Cultural Heritage Wood, Paintings, and Historical Papers. Appl. Sci. 2022, 12, 12846. https://doi.org/10.3390/app122412846

Fornari A, Rossi M, Rocco D, Mattiello L. A Review of Applications of Nanocellulose to Preserve and Protect Cultural Heritage Wood, Paintings, and Historical Papers. Applied Sciences. 2022; 12(24):12846. https://doi.org/10.3390/app122412846

Chicago/Turabian StyleFornari, Anastasia, Marco Rossi, Daniele Rocco, and Leonardo Mattiello. 2022. "A Review of Applications of Nanocellulose to Preserve and Protect Cultural Heritage Wood, Paintings, and Historical Papers" Applied Sciences 12, no. 24: 12846. https://doi.org/10.3390/app122412846

APA StyleFornari, A., Rossi, M., Rocco, D., & Mattiello, L. (2022). A Review of Applications of Nanocellulose to Preserve and Protect Cultural Heritage Wood, Paintings, and Historical Papers. Applied Sciences, 12(24), 12846. https://doi.org/10.3390/app122412846