Simulation of Test Arch Based on Concrete Damage Plasticity Model and Damage Evolution Analysis

Abstract

:1. Introduction

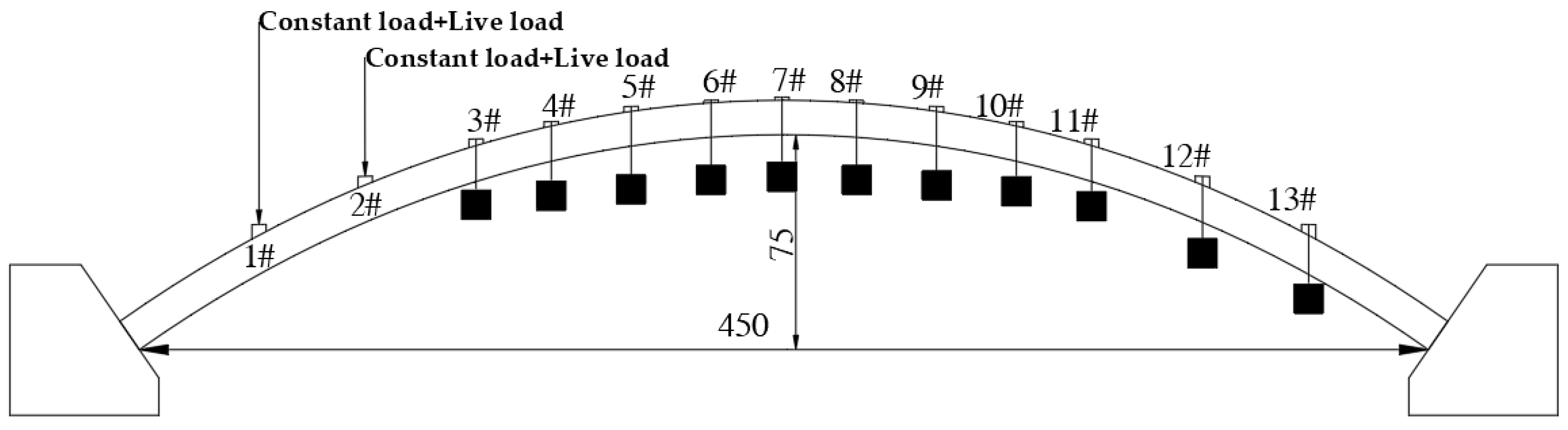

2. Overview of the Experiment

3. Concrete Plastic Damage Model

3.1. Fundamentals

3.2. CDP Model Parameterization

4. Simulation Model Construction

4.1. Model Construction and Validation

4.2. Initial Damage Simulation Approach

4.3. Quasi-Static Computational Assessment

5. Analysis of Results

5.1. Analysis of Displacement Results

5.1.1. Damage Conditions at Arch Foot Base Plate

5.1.2. Damage Conditions at the Top Plate of the Arch Foot

5.1.3. Damage Conditions at the Top and Bottom of the Arch Hance

5.2. Analysis of Structural Damage Evolution

5.2.1. Damage Conditions at the Foot of the Arch

5.2.2. Arch Hance Damage Conditions

5.2.3. Structural Damage Distribution

5.3. Analysis of Reinforcement Forces at the Damage Site

- Once the concrete underwent comprehensive failure throughout the cross-section, the stress within the primary reinforcement predominantly remained beneath the yield strength of 465 MPa [16]. This signified that the reinforcing bars largely sustained an elastic stress state, with the predominant structural failure stemming from the concrete’s collapse.

- Compared to the reinforcing bars in the top slab, the reinforcing bars in the arch foot bottom slab experienced higher stress. In the reinforcement design, the specifications of the reinforcing bars in the top and bottom slabs can be adjusted based on the most unfavorable conditions, aiming to save materials while ensuring the load-bearing requirements are met.

- Compared to damage at the bottom slab of the arch hance, damages sustained by the top slab resulted in the reinforcing bars undergoing augmented stress levels. This escalation in stress was witnessed earlier. Nevertheless, the change in stress for both the top and bottom plate reinforcements followed a similar trend, indicating that the damage location exhibited no significant impact on the development of reinforcement stress.

6. Conclusions

- Displacement data comparison revealed that top plate damage critically influenced structural failure more than bottom plate damage. The ductile nature of top plate failure contrasted with the brittle bottom plate failure, offering better prospects for engineering monitoring and strengthening. Foot damage notably affected structural failure more than hance damage.

- Both foot and hance damage in the arch began at the section corners. Initial damage rates primarily influenced early damage evolution, with less impact on subsequent trends. To mitigate damage, a crack prevention mesh could be incorporated at section corners.

- In the event of substantial local material failure, even if most reinforcing bars remained unyielded, the bottom plate bars faced more challenging conditions. Consequently, the reinforcement design should recalibrate specifications and ratios for both plates based on these conditions.

- Given laboratory test constraints, this study primarily assessed the eccentric loading of arch ribs. Upcoming research will delve into damage evolution under midspan loading, striving for a comprehensive understanding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, B.; Liu, J.; Habib, T. Recent Research and Application of Arch Bridges in China; Springer International Publishing: Cham, Switzerland, 2019; pp. 536–544. [Google Scholar]

- Lin, S.S.; Chen, B.C.; Wu, Q.X. Discussion on Calculation Methods for Load Bearing Capacity of Concrete Arch Bridges. In Proceedings of the 2013 Fourth International Conference on Digital Manufacturing & Automation, Shinan, China, 29–30 June 2013; pp. 492–496. [Google Scholar]

- Liu, J.; Chen, B.; Li, C.; Zhang, M.; Mou, T.; Tabatabai, H. Recent application of and research on concrete arch bridges in China. Struct. Eng. Int. 2023, 33, 394–398. [Google Scholar] [CrossRef]

- Yang, J.; Chen, R.; Zhang, Z.; Zou, Y.; Zhou, J.; Xia, J. Experimental study on the ultimate bearing capacity of damaged RC arches strengthened with ultra-high performance concrete. Eng. Struct. 2023, 279, 115611. [Google Scholar] [CrossRef]

- Yang, J.; Huang, L.; Tong, K.; Tang, Q.; Li, H.; Cai, H.; Xin, J. A Review on Damage Monitoring and Identification Methods for Arch Bridges. Buildings 2023, 13, 1975. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.; Li, C.; Xu, F.; Pan, J. Damage analysis and numerical simulation for failure process of a reinforced concrete arch structure. Comput. Struct. 2005, 83, 2609–2631. [Google Scholar] [CrossRef]

- Fan, Y.; Zhou, J.; Hu, Z.; Zhu, T. Study on mechanical response of an old reinforced concrete arch bridge. Struct. Control. Health Monit. 2007, 14, 876–894. [Google Scholar] [CrossRef]

- Kamiński, T.; Bień, J. Application of kinematic method and FEM in analysis of ultimate load bearing capacity of damaged masonry arch bridges. Procedia Eng. 2013, 57, 524–532. [Google Scholar] [CrossRef]

- Conde, B.; Drosopoulos, G.; Stavroulakis, G.; Riveiro, B.; Stavroulaki, M. Inverse analysis of masonry arch bridges for damaged condition investigation: Application on Kakodiki bridge. Eng. Struct. 2016, 127, 388–401. [Google Scholar] [CrossRef]

- Witzany, J.; Zigler, R. Rehabilitation design of a historic concrete arch bridge in Prague from the early 20th century. J. Perform. Constr. Fac. 2020, 34, 04020056. [Google Scholar] [CrossRef]

- Khorraminejad, A.; Shiravand, M.R.; Safi, M. Damage Analysis of Concrete Open-Spandrel Deck Arch Bridges under Seismic Loads. J. Bridge. Eng. 2022, 27, 04022069. [Google Scholar] [CrossRef]

- Ma, Y.; Xu, F.; Wang, L.; Zhang, J.; Zhang, X. Influence of corrosion-induced cracking on structural behavior of reinforced concrete arch ribs. Eng. Struct. 2016, 117, 184–194. [Google Scholar] [CrossRef]

- Xin, J.; Wang, J.; Liu, Z.; You, X.; Zhou, J. Experimental Study on Bearing Capacity of Corroded Reinforced Concrete Arch Considering Material Degradation. Front. Mater. 2022, 9, 847193. [Google Scholar] [CrossRef]

- Chen, B.C.; Lin, S.S. A state-of-the-art on the ultimate load-carrying capacity of reinforced concrete arches. J. Fuzhou Univ. 2014, 42, 282–289. [Google Scholar] [CrossRef]

- Peng, W.P. Research on Optimization of Cable Force and Arch Ring Stress Regulation during the Construction Period of Large-Span Cantilever Cast Concrete Arch Bridge. Ph.D. Thesis, Changsha University of Science and Technology, Changsha, China, 2020. [Google Scholar]

- Li, J. Research on Moment Increase Coefficient of Reinforced Concrete Arch Bridge. Ph.D. Thesis, Southwest Jiaotong University, Chengdu, China, 2012. [Google Scholar]

- Mirgal, P.; Singh, R.K.; Banerjee, S. Acoustic and fracture energy correlation in mode I fracture with concrete damage plasticity model and three-point bend experiment. J. Mater. Civil. Eng. 2023, 35, 04023002. [Google Scholar] [CrossRef]

- Park, H.W.; Lee, J.H.; Jeong, J.H. Finite Element Analysis of Continuously Reinforced Bonded Concrete Overlay Pavements Using the Concrete Damaged Plasticity Model. Sustain. Sci. 2023, 15, 4809. [Google Scholar] [CrossRef]

- Hafezolghorani, M.; Hejazi, F.; Vaghei, R.; Jaafar, M.B.; Karimzade, K. Simplified damage plasticity model for concrete. Struct. Eng. Int. 2017, 27, 68–78. [Google Scholar] [CrossRef]

- China Academy of Building Research, Tsinghua University, Tongji University. Code for Design of Concrete Structures; China Building Industry Press: Beijing, China, 2010. [Google Scholar]

- Genikomsou, A.S.; Polak, M.A. Finite element analysis of punching shear of concrete slabs using damaged plasticity model in ABAQUS. Eng. Struct. 2015, 98, 38–48. [Google Scholar] [CrossRef]

- Othman, H.; Marzouk, H. Applicability of damage plasticity constitutive model for ultra-high performance fibre-reinforced concrete under impact loads. Int. J. Impact. Eng. 2018, 114, 20–31. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Helmut, K.; Hubert, K.H.; Hubert, R. Behavior of Concrete Under Biaxial Stresses. J. Proc. 1969, 66, 656–666. [Google Scholar] [CrossRef]

- Minh, H.L.; Khatir, S.; Wahab, M.A.; Cuong-Le, T. A concrete damage plasticity model for predicting the effects of compressive high-strength concrete under static and dynamic loads. J. Build. Eng. 2021, 44, 103239. [Google Scholar] [CrossRef]

- Ren, W.; Sneed, L.H.; Yang, Y.; He, R. Numerical simulation of prestressed precast concrete bridge deck panels using damage plasticity model. Int. J. Concr. Struct. Mater. 2015, 9, 45–54. [Google Scholar] [CrossRef]

- Tawfik, A.B.; Mahfouz, S.Y.; Taher, S. Nonlinear ABAQUS Simulations for Notched Concrete Beams. Aci. Mater. J. 2021, 14, 7349. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.H.; Ma, C.; Yang, S.Y.; Wang, P.Z. Performance Study of RC Hollow Core Slab with Cracks Based on Extended Finite Element Method (XFEM). In Proceedings of the CICTP 2020, Xi’an, China, 2–5 July 2020; pp. 1106–11118. [Google Scholar]

- Wang, G.; Lu, W.; Zhou, C.; Zhou, W. The influence of initial cracks on the crack propagation process of concrete gravity dam-reservoir-foundation systems. J. Earthq. Eng. 2015, 19, 991–1011. [Google Scholar] [CrossRef]

- Yazdani, M.; Habibi, H. Residual capacity evaluation of masonry arch bridges by extended finite element method. Struct. Eng. Int. 2023, 33, 183–194. [Google Scholar] [CrossRef]

- Bradford, M.A.; Liu, X.; Chen, C.; Wang, J. Finite element modelling of lattice angle steel structures exposed to wildland fires. Structures 2023, 56, 104901. [Google Scholar] [CrossRef]

- Koman, H. Strengthening of RC frames with infill walls using high strength lightweight concrete panels. J. Sustain. Constr. Mater. Tech. 2023, 8, 120–133. [Google Scholar] [CrossRef]

| Dead Load Values | Live Load Values | ||||

|---|---|---|---|---|---|

| Loading Point | Load (kN) | Loading Point | Load (kN) | Loading Point | Load (kN) |

| 1# | 5.48 | 8# | 1.07 | 1# | 4.79 |

| 2# | 3.79 | 9# | 1.23 | 2# | 4.79 |

| 3# | 3.49 | 10# | 1.33 | ||

| 4# | 1.33 | 11# | 3.49 | ||

| 5# | 1.23 | 12# | 3.79 | ||

| 6# | 1.07 | 13# | 5.48 | ||

| 7# | 3.08 | ||||

| Number | 1# Point Loading Value (kN) | 2# Point Loading Value (kN) | Cumulative Live Load Multiplier | Number | 1# Point Loading Value (kN) | 2# Point Loading Value (kN) | Cumulative Live Load Multiplier |

|---|---|---|---|---|---|---|---|

| 1 | 1.82 | 1.99 | 0.40 | 8 | 0.86 | 1.28 | 1.88 |

| 2 | 2.04 | 2.15 | 0.84 | 9 | 1.00 | 0.78 | 2.07 |

| 3 | 1.15 | 0.78 | 1.04 | 10 | 0.87 | 0.90 | 2.25 |

| 4 | 0.79 | 0.86 | 1.21 | 11 | 1.03 | 1.41 | 2.51 |

| 5 | 1.23 | 1.07 | 1.45 | 12 | 1.16 | 0.94 | 2.73 |

| 6 | −0.28 | 0.00 | 1.42 | 13 | 1.01 | 0.84 | 2.92 |

| 7 | 1.32 | 0.98 | 1.66 |

| Tensile Behavior | Compressive Behavior | ||||

|---|---|---|---|---|---|

| Yield Stress (MPa) | Cracking Strain | Damage Parameter | Yield Stress (MPa) | Inelastic Strain | Damage Parameter |

| 2.317 | 0 | 0 | 5.127 | 0 | 0 |

| 2.38 | 0.00003 | 0.16051 | 10.002 | 0.00001 | 0.0163 |

| 1.38 | 0.00015 | 0.53002 | 14.389 | 0.00003 | 0.0366 |

| 0.911 | 0.00025 | 0.68392 | 21.129 | 0.00014 | 0.0958 |

| 0.691 | 0.00035 | 0.75992 | 24.995 | 0.00034 | 0.1688 |

| 0.565 | 0.00044 | 0.80501 | 26.543 | 0.00061 | 0.2446 |

| 0.482 | 0.00053 | 0.83512 | 26.7 | 0.00077 | 0.2812 |

| 0.423 | 0.00062 | 0.85671 | 18.375 | 0.00237 | 0.5616 |

| 0.379 | 0.00071 | 0.87293 | 11.911 | 0.00392 | 0.7078 |

| 0.345 | 0.0008 | 0.88556 | 8.545 | 0.00538 | 0.7842 |

| 0.318 | 0.00089 | 0.89566 | 6.596 | 0.00679 | 0.8297 |

| 0.295 | 0.00098 | 0.90411 | 5.35 | 0.00818 | 0.8596 |

| 0.276 | 0.00107 | 0.91114 | 4.49 | 0.00955 | 0.8807 |

| 0.259 | 0.00115 | 0.91725 | 3.865 | 0.01092 | 0.8963 |

| 0.245 | 0.00124 | 0.92241 | 3.39 | 0.01229 | 0.9083 |

| 0.233 | 0.00133 | 0.92687 | 3.018 | 0.01365 | 0.9178 |

| 0.222 | 0.00142 | 0.93086 | 2.718 | 0.01501 | 0.9256 |

| 0.212 | 0.00151 | 0.93443 | 2.473 | 0.01637 | 0.932 |

| 0.203 | 0.0016 | 0.93763 | 2.267 | 0.01772 | 0.9374 |

| 0.195 | 0.00169 | 0.94048 | 2.093 | 0.01908 | 0.942 |

| 0.188 | 0.00177 | 0.94303 | 1.944 | 0.02044 | 0.946 |

| 0.181 | 0.00186 | 0.94543 | 1.815 | 0.02179 | 0.9495 |

| 0.175 | 0.00195 | 0.94757 | 1.701 | 0.02314 | 0.9525 |

| 0.17 | 0.00204 | 0.94945 | 1.601 | 0.0245 | 0.9552 |

| 0.164 | 0.00213 | 0.95139 | 1.512 | 0.02585 | 0.9576 |

| 0.16 | 0.00222 | 0.95295 | 1.432 | 0.0272 | 0.9598 |

| 0.155 | 0.00231 | 0.95458 | 1.361 | 0.02856 | 0.9618 |

| 0.151 | 0.00239 | 0.956 | 1.296 | 0.02991 | 0.9635 |

| 0.147 | 0.00248 | 0.95737 | 1.237 | 0.03126 | 0.9651 |

| 0.143 | 0.00257 | 0.95868 | 1.183 | 0.03261 | 0.9666 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; Cai, Y.; Shi, H.; Wang, G.; Zhang, Z.; Dai, Y.; Xu, B. Simulation of Test Arch Based on Concrete Damage Plasticity Model and Damage Evolution Analysis. Appl. Sci. 2023, 13, 11239. https://doi.org/10.3390/app132011239

Tian Z, Cai Y, Shi H, Wang G, Zhang Z, Dai Y, Xu B. Simulation of Test Arch Based on Concrete Damage Plasticity Model and Damage Evolution Analysis. Applied Sciences. 2023; 13(20):11239. https://doi.org/10.3390/app132011239

Chicago/Turabian StyleTian, Zhongchu, Yue Cai, Hongtao Shi, Guibo Wang, Zujun Zhang, Ye Dai, and Binlin Xu. 2023. "Simulation of Test Arch Based on Concrete Damage Plasticity Model and Damage Evolution Analysis" Applied Sciences 13, no. 20: 11239. https://doi.org/10.3390/app132011239