Abstract

The main aim of this work was to assess the possibility of using dried walnut leaves (Juglans regia L.) in the production of wheat bread. In the developed recipe, wheat flour was partially replaced with dried and powdered walnut leaves (WLs) in amounts of 0.5%, 1.0%, 1.5%, 2.0% and 2.5%. Serving as a control sample was wheat bread without WLs. The bread was made using a single-phase method using yeast. As part of the research methodology, laboratory baking parameters (dough yield, total oven loss, bread yield), loaf volume and loaf specific volume were determined. Additionally, the colors of the dough, crust and bread crumb were determined in the CIE L*a*b* space. The crumb texture profile was assessed using the TPA test. Additionally, the antioxidant power and the total phenolic content of the dough and bread were tested. The consumer acceptability of the sensory features of the bread was also assessed. The test results were statistically analyzed using a one-way ANOVA. It was found that enriching the bread recipe with WLs had a significant impact on its quality. The control bread had the highest volume, and replacing wheat flour with dried leaves resulted in a significant reduction in volume, which was greater at higher WLs contents. Similarly, as the proportion of WLs in the recipe increased, a significant decrease in the brightness of both the dough and the crumb of the obtained bread was observed. A texture analysis showed that bread with a WLs content of 2.5% was the most different from the control bread and other tested breads. However, it was found that enriching bread with the unconventional addition of walnut leaves had a very good effect on its health benefits. The antioxidant activity and the content of total phenolics in the bread grew with the increase in the share of WLs in the recipe.

1. Introduction

Bread has been present in the diet of people living in various regions of the world for thousands of years [1]. It is a good source of complex carbohydrates, which provide the body with the energy it needs. However, when consumed in too large quantities and when it is part of an unbalanced diet, it may promote problems such as overweight and obesity. Bread consumption in balanced quantities can provide the body with a number of nutrients necessary for its proper functioning [2]. Due to the well-known technology of its industrial production, supply and affordability, bread is also a good base for enrichment with ingredients that improve its nutritional value or shape its health-promoting profile. So far, many possibilities for enriching bread have been described in the literature, starting from the addition of amino acids [3], vitamins [4,5] and minerals [6], through diversifying its organoleptic and nutritional values and composing baking blends [7], to adding unconventional raw materials. One of the possibilities is to enrich bread with the addition of dietary fiber, which, when used in the appropriate dose, makes it functional [8]. The consumption of functional foods can improve the functioning of the human body and prevent diseases. Therefore, bread containing antioxidants such as phenolic compounds may lead to an increase in the supply of these compounds among nutritionally conscious consumers [9,10]. For over a decade, research has been conducted on the possibility of enriching bread with raw materials based on leaves of various botanical origins, as well as in various forms such as powder or extract. Examples of such an addition are green vegetable leaves [11,12], Moringa [13], nettle [14] and quinoa [15] leaves. The discussed studies confirmed the improvement in the health-promoting value of enriched bread, as well as the impact of the additive on the quality of the finished product and its sensory evaluation. The results of sensory analyses showed that with increasing supplementation with leaf-based additives, a significant decrease in the assessment of sensory characteristics was most often noted. Therefore, it seems necessary to search for optimal solutions for supplementation with additives of plant origin and to ensure the expected quality of the enriched finished product. The search for possibilities for enriching bread can be expanded to include plant raw materials with applications typical of herbal medicine or pharmacy, and one of them may be walnut flowers [16] or walnut leaves (Juglans regia L.). Schwindl et al. [17] in the methanol extract from the leaves of Juglans regia L. confirmed the occurrence of 40 metabolites belonging to the glycosides of megastigman, tetralone, phenylpropanoid, neolignan and juglone. Walnut leaf extracts have demonstrated strong antioxidant, antimicrobial, α-glucosidase inhibitory [18] and anticancer [19] effects. There are no studies in the literature on the possibility of introducing a food additive based on walnut leaves. Nevertheless, the literature on the subject mentions that in some other European countries (e.g., Portugal), especially in rural areas, dried walnut leaves are often used to prepare infusions [20]. Therefore, the aim of the study was to investigate the impact of different levels of replacing flour in the wheat bread recipe with dried walnut leaf powder on the quality of the finished product, the health-promoting attributes and the sensory acceptability of wheat bread.

2. Materials and Methods

2.1. Materials and Reagent

Distilled water, methanol, ethanol, Folin-Ciocalteau reagent, ABTS (2,20-azino-bis-3-ethylbenzothiazoline-6-sulfonic acid), TPTZ (iron (III)-2,4,6-tripyridyl-S-triazine), sodium carbonate and iron (III) chloride were used for the chemical analyses. The reagents were sourced from Sigma-Aldrich company (Darmstadt, Germany) and Chempur company (Piekary Śląskie, Poland).

2.1.1. Plant Materials

Young walnut leaves (WLs) (Juglans regia L.) were collected in May 2022 from trees cultivated in the Subcarpatian region (Poland). The leaves were frozen in plastic string bags and then lyophilized using a freeze dryer (ALPHA 1–2 LD plus Martin Christ Gefriertrocknungsanlagen GmbH, Osterode am Harz, Germany). The dried leaves were ground in a laboratory grinder. Wheat flour type 650 (Polskie Młyny, Warszawa, Poland) with a water absorption of 52.8% and a moisture content of 13.5% was used to obtain bread. Baker’s yeast, table salt and tap water were also used.

2.1.2. Preparation of Bread in Laboratory Conditions

The dough was obtained by a single-phase method using yeast, described in detail in a previous work [16]. Briefly, the dough used was wheat flour, baker’s yeast (3% of the flour weight) and table salt (1% of the flour weight). The amount of water (30 °C) required in the recipe for the preparation of a dough consistency of 350 Brabender units was determined using a Farinograph-E (Brabender, Duisburg, Germany) [21]. The control sample was based on wheat flour (control). In the analyzed systems, the flour was replaced with walnut leaf (WLs) powder at 0.5, 1.0, 1.5, 2.0 and 2.5% levels, A–E, respectively. The dough was fermented (30 °C, 60 min) in a fermentation chamber and kneaded after 30 min (2 min, manually). After the fermentation process was finished, the molds with the 250 g dough pieces were placed in the baking chamber of a lassic electric oven model Classic (SvebaDahlen, Fristad, Sweden) and baked (230 °C, 30 min). After baking, the bread was weighed, and after 24 h, the quality of the baked bread was examined in three parallel repetitions.

2.2. Methods

2.2.1. Parameters of the Bread-Baking Process and Bread Quality

As part of the laboratory baking assessment, dough yield, total oven loss and bread yield were calculated [16,21]. The volume of loaves [cm3] was determined using a method involving the laboratory displacement volume of loose millet seeds [22]. Based on the mass and volume of cooled loaves of bread, their specific volume [cm3/g] was also calculated [23]. Photos of loaves and bread crumbs were also taken using a 13 MPix camera (Samsung, Suwon, Republic of Korea). The porosity of the bread crumb was assessed by comparison with the Dallmann scale [24]. The analysis was performed in duplicate.

2.2.2. The Color of the Dough, Bread Crust and Crumb

The color analysis of dough and bread (crust and crumb) was carried out in the CIE L*a*b* space using a spectrophotometer UltraScan Vis (HunterLab, Reston, VA, USA) in three repetitions [16]. As part of this analysis, respectively, the parameter L* was determined, defining the brightness of the sample, and the +a*/−a* and +b*/−b*values represent red/green and yellow/blue colors. In relation to the control sample, the value of the ∆E parameter (total color difference) was also calculated according to the following relationship:

2.2.3. Bread Crumb Texture Analysis

The crumb of the tested wheat breads was subjected to texture profile analysis using an EZ-LX testing machine (Shimadzu, Kyoto, Japan). A single test was performed on a cube-shaped crumb sample (a = 30 mm) cut from the center of the loaf of the tested bread. The sample was compressed twice with a steel probe (d = 25 mm) moving at a speed of v = 50 mm·s−1 to 50% of the initial height of the sample. The tests were carried out using Trapezium X Texture Pl ver. 1.5.6 software (Shimadzu, Kyoto, Japan), and the following parameters were taken into account in the assessment of the texture profile: hardness (N), elasticity (−), cohesiveness (−), gumminess (N), chewiness (N) and resilience (−). Measurements of the texture parameters of each type of tested bread were carried out in four replications [16].

2.2.4. Total Phenolic Content and Antioxidant Potential in Dough and Bread

Sample Preparation

The antioxidant potential and the content of total phenolics in the dough and in the obtained breads were assessed based on the analysis of the prepared extract [16]. In detail, the doughs and breads were frozen, lyophilized in a freeze dryer and ground. Then, 0.5 mL of the powdered material was extracted with 5 mL of 50% methanol solution using an ultrasound bath (Sonic 10, Polsonic, Warsaw, Poland) at 30 °C for 30 min. Following the centrifugation of the mixture and decanting of the solution, the extraction process was carried out once again, utilizing an 80% methanol solution instead. The supernatants were combined and subjected to further analysis.

Total Phenolic Content (TPC)

The total content of phenolics was evaluated by the Folin–Ciocalteu method according to Gao et al. [25]. The assay method was described in detail in a previous work [16]. The experiments were carried out in triplicate, and the results were expressed as gallic acid equivalent per g of dry weight of sample (mg GAE/g dw).

Antioxidant Activity

The scavenging activity was determined by means of a spectrophotometric method with the ABTS cation radical, as described by Re et al. [26] and addressed by Pycia et al. [16]. The assays for the study were conducted in triplicate, and the results were expressed as Trolox equivalent per g of dry weight of sample (mM TE/g dw).

The FRAP (Ferric Reducing Antioxidant Power) test was carried out by a spectrophotometric method developed by Benzie and Strain [27] and addressed by Pycia et al. [16] The tests were executed in triplicate. The findings were expressed in mM TE/g dw.

2.2.5. Sensory Evaluation

After 24 h, the obtained bread was subjected to sensory evaluation by 10 trained panelists (women and men aged 23–35). For this purpose, the bread was cut into small pieces containing both crumb and crust. The bread was coded and served to trained panelists on plastic plates. The assessment of the acceptability of the bread was based on a test using a 9-point hedonic scale, where 1 means “I definitely don’t like it”, 2—“I don’t like it very much”, 3—“I don’t like it moderately”, 4—“I don’t like it a little”, 5—“I neither like nor dislike”, 6—“I like it a little”, 7—“I don’t like it moderately”, 8—“I like it very much” and 9—“I definitely like it very much” [23,28,29,30]. The assessment included external appearance, crumb color, smell, taste, mouth texture and overall acceptability. Between each tasting, panelists cleaned their mouth with tap water (20 °C).

2.3. Statistical Analysis

This analyses were conducted employing the Statistica ver. 13.3 program (TIBCO Software Inc., Palo Alto, CA, USA). The results are shown in tables as means ± SD. All test results were subjected to a one-way ANOVA. The significance of differences between mean values was assessed using the Duncan test at a significance level of p = 0.05. Moreover, Pearson’s linear correlation coefficients were determined between the parameters representing dough and bread (p = 0.05).

3. Results and Discussions

3.1. Parameters of the Laboratory Baking Process

Table 1 shows the results regarding the parameters of the laboratory baking process for the developed wheat bread, in which the flour was replaced with walnut leaf powder (WLs). It was found that the average dough yield was 162%, and the value of this parameter did not depend statistically significantly on the amount of powdered walnut leaves added (p ≥ 0.05). However, the inclusion of WLs in the bread recipe had a significant impact on the value of baking loss because the highest value of this parameter was recorded in dough with a 2.5% share of WLs. Moreover, this dough was also characterized by the highest value of total baking loss (Table 1). Bread yield is an important technological parameter that also determines the profitability of production. It was shown that the partial replacement of wheat flour with the discussed additive usually resulted in a small but statistically significant increase in bread yield (p ≤ 0.05). A similar tendency to change the laboratory baking process parameters was observed in earlier work, in which wheat flour was replaced with dried walnut flowers [16]. The highest value of this parameter was found in bread with 2.0% WLs (Table 1). The research found, among other things, a significant positive linear correlation between the values of parameters showing dough yield and bread yield (r = 0.88, p < 0.05), oven loss and total baking loss (r = 0.97, p < 0.05).

Table 1.

Laboratory baking parameters of wheat dough with J. regia leaves.

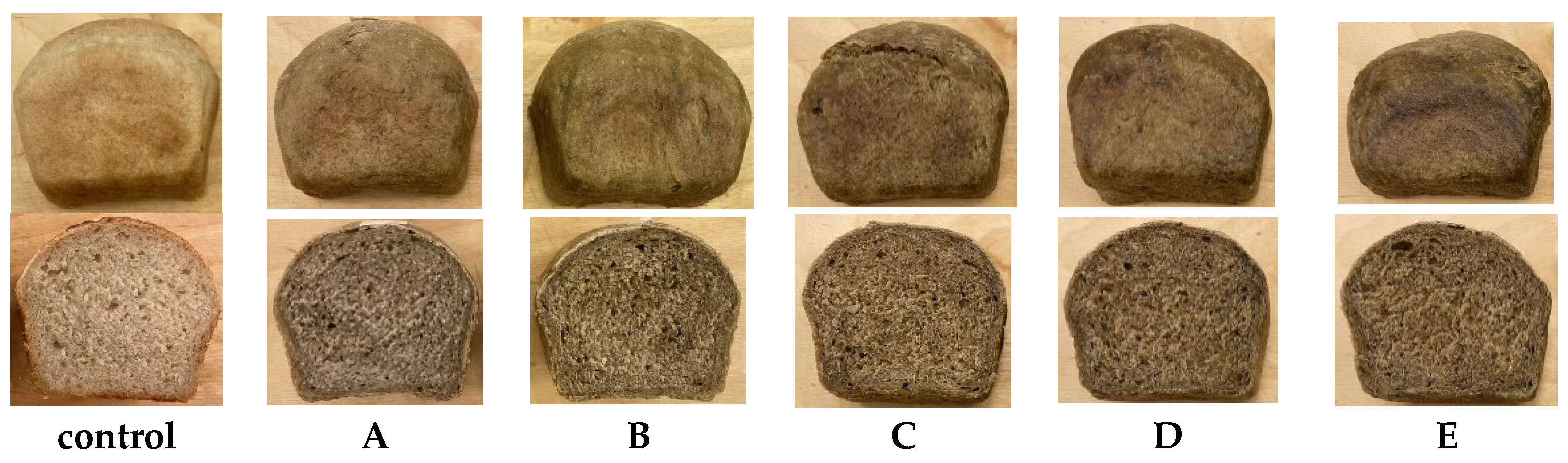

The volume of bread is a physical parameter significantly related to the degree of consumer acceptability. According to Dziki et al. [30], the volume of a loaf of bread indirectly informs us about the consistency of the dough, the course of fermentation, aeration and the porosity of the crumb. It was shown that replacing flour with WLs powder resulted in a significant decrease in the volume of loaves (p ≤ 0.05) of the tested wheat bread (Table 1). The control bread had the largest volume, and the bread with a 2.5% WLs content had the smallest volume (420 cm3). This volume difference was significant and visually noticeable (Figure 1). This is consistent with observations from our previous work [16], where wheat bread was enriched with dried walnut flowers. The reason for the reduction in the volume of the loaves of the enriched bread is probably the weakening of the gluten network built during kneading the dough. As a result, the CO2 from the fermentation process is not fully retained because the more of this gas retained, the softer and more flexible the crumb is, and the greater the volume. The relationship between the volume of the loaves and their weight is expressed as the specific volume. It was shown that the specific volume of the control bread was 2.44 g/cm3, which may be due to the activity of yeast, the conditions of the fermentation action or the quality of the recipe ingredients. The research showed that breads containing WLs were characterized by a statistically significantly lower value of this parameter compared to the control sample (p ≤ 0.05), and the specific volume decreased as the share of walnut leaves in the recipe of the tested breads increased. The statistical analysis performed showed a strong positive correlation between the volume and the specific volume of the loaves (r = 0.99, p < 0.05). According to other researchers [31,32], the average specific volume of wheat bread was from 3.5 to 5.0 g/cm3. In the case of gluten-free bread, it is usually about 2 g/cm3. According to Krupa-Kozak et al. [32], specific volume is one of the most important technological indicators proving the quality of bread, but it is not the only or most important one. Equally important is the porosity of the crumb, which is measured by the uniformity of the distribution and the size of the gas bubbles that create the crumb structure. The conducted research (Table 2) showed that the share of WLs in the bread recipe resulted in a significant reduction in the value of this parameter (p ≤ 0.05) in the tested bread. Similar observations were reported by Dziki et al. [30] and Pycia et al. [16] in their studies on the effect of supplementing wheat flour with appropriately dried parsley leaves and walnut flowers. Similarly, Baiano et al. [33] found a decrease in the specific volume of wheat bread enriched with plant extracts (celery, chicory, cabbage, fennel, olive leaves, grape pomace). The specific volume decreased in the order control > fennel > grape pomace > chicory and celery > cabbage and olive leaves. According to Baiano et al. [33], the reduction in bread volume may result from the action of the acidic plant extract components denaturing the gluten network. Moreover, the bioactive substances present in the extract modified the physical properties of the bread dough. This was due to the possibility of forming complexes between antioxidants and proteins and polysaccharides, stabilized by hydrogen and covalent bonds. The hydrophobic bonds in the polyphenol–protein system are also responsible for the stability of the complexes [34]. Moreover, the participation of WLs in the dough recipe could have an adverse effect on the activity of yeast, the product of which is, among others, carbon dioxide. This may be due to the antibacterial properties of the leaves of Juglans regia L., as confirmed by the research of Pereira et al. [20]. WLs selectively inhibited the growth of Gram-positive bacteria. Bacillus cereus was the most susceptible one (MIC 0.1 mg/mL). However, Gram-negative bacteria and fungi were resistant to the extracts at 100 mg/mL. Moreover, the tests used wheat flour, which is the only flour that contains gliadin and glutenin in appropriate proportions. The gluten that forms is responsible for the volume of the loaves and the hardness of the crumb. The use of a plant additive instead of flour results in a dilution of the gluten in the dough and thus reduces the volume of the resulting bread [30]. However, Krupa-Kozak et al. [32] observed an increase in the specific volume of gluten-free bread enriched with dried broccoli leaves. According to the cited authors, prior heat treatment of the leaves by blanching resulted in the inactivation of enzymes and thus did not show any inhibitory effect on the activity of yeasts responsible for the fermentation process. The results of the discussed studies (Table 2) also showed that the crumb of the tested breads with the addition of powdered walnut leaves was generally of good porosity, similar to that noticed in the tests of the control bread. The deterioration of the product in terms of the discussed quality factor was noted when the highest share of the tested additive was used (2.5%) in the baking blend for making bread.

Figure 1.

External appearance of the loaf and crumb of the control and test breads. (A–E): the systems in which the flour was replaced with walnut leaf powder at 0.5, 1.0, 1.5, 2.0 and 2.5% levels, respectively.

Table 2.

Bread volume of wheat dough with J. regia leaves.

3.2. Color of Dough and Bread

Table 3 and Table 4 present the average values of the parameters for the instrumental color analysis of the dough and bread, respectively, according to the developed recipe. It was shown that the use of WLs had a statistically significant effect (p ≤ 0.05) on all the analyzed parameters. In the case of dough (Table 3), it was found that the highest value of the L* parameter, informing about the brightness of the sample, was characteristic for the control sample, and the addition of WLs resulted in a statistically significant reduction in the value of this parameter (p ≤ 0.05) (from 80.43 (control) to 59.17 (E)). In turn, the a* parameter in the dough samples containing WLs took on negative values, which indicates a greater share of green color, increasing with the increase in the WLs content in the bread recipe. An increase in the value of the b* parameter, which is a measure of the share of yellow/blue color, was also found. The value of the total color difference (∆E) of the samples with WLs increased statistically significantly compared to the control sample because the higher the value of this parameter, the easier it is to notice color differences with the naked eye. To classify differences in the perceived color of the wheat bread control sample and the wheat bread with WLs addition, the criterion given by Adekunte et al. [35], very distinct (∆E > 3), distinct (1.5 < ∆E < 3) and small difference (∆E < 1.5), was applied. Differences in the color of the dough are the result of the substitution of wheat flour with WLs. WLs contain chlorophyll, which determines the green shade of the color of both the dough and bread, and the greater the proportion of WLs, the greater this green shade. A similar tendency was noticed by Krupa-Kozak et al. [32] when analyzing the color of gluten-free bread enriched with dried broccoli leaf powder (BLP). The cited authors also confirmed a decrease in the value of the L* parameter; the a* parameter had negative values, and the b* parameter had higher values with the increasing share of BLP. The cited authors explained this color change by the well-preserved ingredients of the raw material in the freeze-drying process. A similar pattern of changes in the color of the crumb of wheat bread enriched with powdered parsley leaves was observed by Dziki et al. [30]. In the described studies, walnut leaves (Table 3) were also dried using the freeze-drying method. The dough took on a greenish color, and the bread, as a result of the baking process and the thermal degradation of dyes, turned brown. In an earlier study [16], concerning the enrichment of wheat bread with dried walnut flower powder, a decrease in the L* value and a decrease and an increase in the value of the a* and b* parameters, respectively, were observed as the share of the discussed plant-based additive increased.

Table 3.

Color of wheat dough with J. regia leaves.

Table 4.

Color of wheat bread with J. regia leaves.

In relation to the analysis of bread color (crust and crumb), similarly to Krupa-Kozak et al. [32] and Dziki et al. [30], a decrease in the value of the L* parameter was observed for both the crust and crumb. However, the a* parameter in the crumb color of all the breads had positive values, and, similarly to the b* parameter, its value increased as the WLs content increased (Table 4), and as a consequence, an increase in the total color difference (∆E) was noted. The average value of the L* parameter of the crust and crumb of the breads containing WLs was 56.27 and 46.10, respectively, and was lower compared to the values recorded in the control tests by approximately 10% and 37%, respectively, for the crust and crumb. The parameter a* and the parameter b* took positive values, which indicates a dominant share of red and blue colors, respectively. In both the crust and crumb, a clear increase in the value of the ∆E parameter was observed with the increasing share of WLs in the recipe of the tested bread. This is confirmed by the noticeable darkening of the color under the influence of the discussed plant additive (Figure 1). A similar pattern of changes in the color of the crust and crumb of the wheat bread containing dried walnut flower powder was recorded in a study by Pycia et al. [16]. Baiano et al. [33] examined the color of wheat bread enriched with extracts from plant byproducts (extracts from chicory, cabbage, celery, fennel, olive leaf and grape marc wastes) and found that replacing water with extracts resulted in a significant reduction in the brightness of the crumb and a shift in color towards a red color. In the case of the b* parameter, it was found that the color of the enriched bread had yellowish shades, while the color of the bread with celery extract was similar to the control sample. The darkening of the crust and crumb color of gluten-free bread enriched with Moringa oleifera leaf powder was also confirmed by Bourekoua et al. [23]. As the cited authors explain, the color change results from the high chlorophyll content in the tested plant additive. In the analyzed case, the colors of both the dough and bread (crust and crumb) are determined by the chemical composition of the walnut leaves. According to Kohlmunzer [36] and Pereira et al. [20], the dominant active ingredients of the fresh leaves of plants of the genus Juglans regia L. are hydrolysable tannins (elago- and gallotannins) and 1,4,5-trihydroxynaphthalene-4-beta-D-glucoside, which is converted into a naphthoquinone derivative called juglone as a result of drying. Jualgae is a quinone dye that acts as an allelopathic compound in the plant, causing the slower growth or even death of plants growing nearby. It occurs in the leaves, roots and shells of Juglans regia L. In addition, walnut leaves contain flavonoids, phenolic acids, carotenoids, triterpenes and other compounds. The research conducted included, among other things, a significant positive linear correlation between the values of dough color parameters such as L*, a* and ∆E and the volume of the bread loaves, respectively (r = 0.97, r = 0.91, r = −0.99, p < 0.05), and the specific volume of the bread loaves, respectively (r = 0.94, r = 0.91, r = −0.97, p < 0.05). A positive linear correlation was also found between the value of the L* parameter for the bread crust and crumb and the volume of the loaves (r = 0.93, r = 0.97, p < 0.05) and the specific volume of the bread (r = 0.92, r = 0.98, p < 0.05).

3.3. Textural Parameters of Bread Crumb

The crumb texture of the tested breads with the walnut leaf powder addition differed statistically significantly in terms of most of the parameters tested compared to the control bread crumb (Table 5). The use of the additive resulted in a statistically significant (p ≤ 0.05) increase in the crumb hardness of the obtained test breads compared to the control bread, and at the same time, there was no impact of the amount of the additive on the variation in the discussed parameters among the breads tested with the addition of J. regia L. leaves. A similar relationship was observed in the variation in crumb hardness and was noted in studies by other authors regarding bread enriched with Moldavian dragonhead leaves [37]. The use of the addition of walnut leaves deteriorated the elasticity of the crumb of the tested bread, and the lower the value of this parameter, the greater the share of the additive in the blend from which the tested bread was produced (Table 5). The cohesion of the crumb of wheat bread with the addition of 2.0 and 2.5% WLs was clearly lower in comparison to both the control sample and the tested samples, but with a lower share of the additive. In the textural tests, the influence of the share of additive used on the variation in the gumminess and chewiness of the crumb of the enriched breads and the control bread was also noted. As in the case of hardness, the differences in the amount of the additive were not reflected in the differences in the values of these parameters when comparing the tested breads. It was noticed that only when higher proportions of powdered J. regia L. leaves were used were changes in the gumminess (2.0%) and chewiness (2.0 and 2.5%) of the crumb of the tested bread noted. The variability in bread crumb resilience under the influence of the tested additive was similar.

Table 5.

Textural parameters of wheat bread crumb with J. regia leaves.

The effect of additions of various plants’ leaves on the texture of bread has been the subject of previous research, and the results of such bread supplementation have been varied. The analysis of the texture of bread with the addition of dried and powdered sweet potato leaves and stems showed slight changes in cohesion, while the hardness and chewiness of the crumb of bread with the addition of more than 5% were significantly higher compared to the control sample [38]. In studies by other authors [39], after adding sweet potato leaf powder, the hardness of steamed bread gradually increased, and the gumminess and chewiness increased to varying degrees. Other authors did not note the influence of the share of additives such as Moldavian dragonhead leaves [37] or parsley leaves [30] in the baking blend on changes in the values of selected texture parameters of the finished product. The shaping of the crumb texture under the influence of various leaves depends on the origin of the raw material, including its chemical composition and the share of it in the recipe for bread baking. A linear correlation was demonstrated between the elasticity of bread and, among others, the volume of loaves, the specific volume, and the dough color parameters L*, a*, ∆E and L* for the crust and bread crumb, respectively (r = 0.96, r = 0.96, r = 0.92, r = 0.99, r = −0.94, r = 0.89, r = 0.99, p < 0.05). However, the cohesiveness of bread correlated, among others, with the L* parameter for the dough and crust and the chewiness of the bread crumb, respectively (r = 0.90, r = 0.93, r = 0.91, r = 0.97, p < 0.05). In turn, the crumb chewiness correlated with the volume of the loaves, the L* parameter for the dough and crust, and the crumb cohesion and gumminess (r = 0.90, r = 0.96, r = 0.92, r = 0.97, r = 0.88, p < 0.05).

3.4. Total Phenolic Content and Antioxidant Potential of Dough and Bread

Juglans regia L. leaves are a good source of polyphenols. According to the latest reports, they include several bioactive compounds with anticancer and antimicrobial potential, mainly phenolic acid derivatives, tannins, and flavonoids [19,20,40].

The values of the total phenolic content (TPC) and antioxidant power of the dough and resulting bread containing different WLs shares by means of ABTS and FRAP methods are shown in Table 6 and Table 7.

Table 6.

Antioxidant activity of wheat dough with J. regia leaves.

Table 7.

Antioxidant activity of wheat bread with J. regia leaves.

As expected, the TPC and the antioxidant power of both the dough and bread progressively increased as the share of WLs in the recipe grew. The phenomenon of an increase in the TPC and antioxidant properties was observed by other authors in their works on the addition of various ingredients to wheat bread. Pycia and Ivanisova [41] and Pycia and Kapusta [42] demonstrated an increase in the TPC and the antioxidant activity in breads enriched with dry walnuts and hazelnuts, as well as walnuts and hazelnuts at different stages of ripeness. Similarly, Dziki et al. [30], Gawlik-Dziki et al. [43], Cacak-Pietrzak et al. [44], Lee and Kim [45], Taglieri et al. [46] and Mata-Ramírez et al. [47] observed an increase in the polyphenol content together with antioxidant properties in bread formulations supplemented with parsley leaves, onion, dandelion, sea buckthorn, citrus albedo or hibiscus flowers, respectively. In the present study, the addition of 2.5% leaf content to dough and bread resulted in an augmentation in the TPC of 135% and 217%, respectively, compared to the control samples. In turn, the antioxidant potential was increased by 110% and 190% as measured by the ABTS method and 514% and 516% by means of the FRAP assay with respect to the dough and bread with no WLs addition. The obtained data are consistent with our previous investigations regarding the fortification of bread with walnut male inflorescences [16]. In that study, relative to the control group, the TPC increased by 115% in wheat dough enriched with 2.5% walnut flowers and by 316% in 2.5% fortified bread. Similarly, the inclusion of 2.5% inflorescence lyophilizate led to an elevation in the antioxidant power of the dough and bread by 363% and 299%, respectively, as measured by the FRAP method. Therefore, it can be summarized that, like the flowers, leaves are a great example of a byproduct of a walnut tree and are rich in health-promoting substances that can be exploited in the process of food enrichment.

Further, the content of polyphenols as well as the antioxidant potential of bread decreased compared to the TPC and the antioxidant action in the corresponding dough. Such an observation has already been noted in the bread-baking process [48,49,50]. However, the opposite phenomenon, i.e., the TPC and the antioxidant values significantly increased in the enriched bread with respect to the unbaked control groups, was previously reported [51]. In food products, phenolic compounds exist within complex multi-component systems, where interactions can influence their activity and stability. The stability of polyphenols during processing is influenced by various internal and external factors, including the molecular structure, pH, temperature, oxygen, light exposure, processing conditions, and interactions with other compounds and components [52]. The antioxidant potential of bread is also shaped by the participation of Millard reaction products, most of which are found in the bread crust [33]. The statistical analysis performed showed a strong correlation between the content of total phenols in the dough and parameters such as the loaf volume; the specific volume; the L*, a* and ∆E of the dough; the L*, b* and ∆E of the crust; and the L* and ∆E of the crumb, respectively (r = −0.97, r = −0.95, r = −0.97, r = −0.94, r = 0.97, r = −0.96, r = −0.88, r = 0.95, r = −0.96, r = 0.96, p < 0.05). Moreover, the TPC of the dough negatively correlated with the bread texture parameters such as elasticity, cohesiveness and chewiness, respectively (r = −0.95, r = −0.91, r = −0.96, p < 0.05). Moreover, the TPC of the dough had a strong positive correlation with all the parameters showing the antioxidant potential and the content of total polyphenols in the dough and bread (average value r = 0.98, p < 0.05).

The content of total phenolics in the bread also strongly correlated with parameters such as the loaf volume; the specific volume; the L*, a* and ∆E of the dough; the L* and ∆E of the crust, L*; and the ∆E of the crumb, respectively (r = −0.98, r =−0.96, r = −0.98, r = −0.95, r = 0.98, r = −0.94, r = 0.93, r = −0.97, r = 0.97, p < 0.05). Moreover, the bread’s TPC negatively correlated with bread texture parameters such as elasticity, cohesiveness and chewiness, respectively (r = −0.97, r = −0.89, r = −0.95, p < 0.05).

3.5. Sensory Analysis

The bread was subjected to a sensory analysis. The mean results of hedonic tests on different kinds of enriched bread with WLs are presented in Table 8. A comparison of the results of the consumer acceptance assessment of wheat bread with the addition of WLs confirmed the varied impact on the assessed sensory parameters of the finished product. The assessment of external appearance was in the range of 6.8–8.4, but no statistically significant differences in the results were confirmed. In the opinion of the panelists, the color of bread with an additive content of 1.5% and more was less acceptable compared to the control bread as well as compared to the color of bread with a lower share of the additive in the baking blend used to produce them. The acceptability of the smell of the tested breads decreased with the increasing share of the additive in the recipe. The taste of the tested breads with the addition of walnut leaves was less acceptable at higher shares of the additive, with the worst rated breads having 2.0 and 2.5% additions. It seems interesting that the average values of the mouth texture assessment of the crumb of the tested breads did not differ, which may indicate that the greatest contribution to the assessment of this feature could have been the crumb hardness, which was not significantly differentiated by the amount of additive. It was confirmed that the acceptability of the finished product decreased with the increase in the share of the additive in the recipe of the tested wheat bread. The tested bread with the lowest content (0.5%) of powdered leaves of J. regia L. (A) was characterized by the highest acceptability, similar to the control sample. As the share of the additive increased, lower acceptability of the tested sensory parameters and overall acceptability of the finished product were noted. Research results similar to the ones discussed (Table 8) were also obtained by Dziki et al. [37]. The highest ratings in terms of the assessment of the sensory characteristics of bread were obtained for control bread samples and those with the lowest percentage of Moldavian dragonhead leaves, and the differences in the overall assessment of these breads did not differ statistically significantly. In bread with the addition of powdered coriander leaves at supplementation levels of 1.0, 3.0, 5.0 and 7.0% (w/w) of wheat flour, a significant improvement in sensory characteristics was observed. It was found that a content of coriander leaves ranging from 3.0 to 5.0% was the optimal level of supplementation, ensuring the best compromise in terms of the highest acceptability of fortified bread [53]. Studies by other authors also noted a relationship between the sensory acceptability of breads and the addition of Moringa leaves, but the substitution with the addition in the discussed studies was much higher, up to 20% [13]. A variation in the acceptability of the finished product limited by the share of additive content in the recipe was also noted in studies on the use of bread enrichment with cheeseweed mallow leaves (MPLPs) [54]. The highest ratings in terms of sensory evaluation were obtained for bread samples enriched with 2% and 3% MPLPs, while the lowest ratings were obtained for bread enriched with 4% and 5% MPLPs. The consumer acceptability of a product enriched with a leaf-based additive was often determined by the level of change in color, and it has a greater share of the green component and a possible deterioration of taste with a distinct bitter aftertaste, as indicated by the cited authors in their research. Similar relationships were observed in the discussed studies (Table 8).

Table 8.

Results of consumer acceptance test of examined bread.

4. Conclusions

In this work, an attempt was made to use dried and powdered walnut leaves as an enriching agent for wheat bread. The physical, antioxidant and sensory characteristics of the bread were significantly modified by the addition of powdered walnut leaves, which makes it a valuable functional additive useful for shaping the functional properties of bread. The analysis of the total phenolic content and antioxidant potential showed that this plant-based material could be a cheap and easily accessible source of valuable plant bioactive substances such as chlorophylls, flavonoids and carotenoids for the consumer. It was shown that the antioxidant potential and the content of total phenolics in the bread increased with an increasing level of WLs. This indicates an improvement in the potential health-promoting profile of wheat bread containing this unconventional additive, rich in health-beneficial bioactive substances. Analyzing the test results, it can be assumed that the most optimal supplementation was 0.5% flour and 1.0% powdered leaves because this level of supplementation improved the antioxidant profile but did not cause a significant deterioration in the sensory quality of the tested bread. The discussed research results also provide the opportunity to continue research on the usefulness of J. regia L. leaf powder for food enrichment. In terms of specific dietary recommendations, further research is required to identify the phenolic profile of bread. Moreover, it seems valuable to carry out storage tests for bread with the additive in question, its durability and the degree of preservation of biological activity carried by walnut leaf powder in order to develop comprehensive technological recommendations.

Author Contributions

Conceptualization, K.P.; methodology, K.P., A.M.P. and J.K.; formal analysis, K.P., A.M.P. and J.K.; investigation, K.P., A.M.P. and J.K.; resources, K.P. and A.M.P.; data curation, K.P., A.M.P. and J.K.; writing—original draft preparation, K.P., A.M.P. and J.K.; writing—review and editing, K.P., A.M.P. and J.K.; visualization, K.P., A.M.P. and J.K.; supervision, K.P.; project administration, K.P.; funding acquisition, K.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

The sensory evaluation in this study is an expert evaluation, so we did not need to apply for approval from the Ethics Committee. The study does not fall within the scope of mandatory tests to be submitted to the Ethics Committee.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pallant, E. Sourdough Culture: A History of Bread Making from Ancient to Modern Bakers; Agate Publishing: Evanston, IL, USA, 2021. [Google Scholar]

- Kourkouta, L.; Koukourikos, K.; Iliadis, C.; Ouzounakis, P.; Monios, A.; Tsaloglidou, A. Bread and health. J. Pharm. Pharmacol. 2017, 5, 821–826. [Google Scholar] [CrossRef]

- Meybodi, N.M.; Mirmoghtadaie, L.; Sheidaei, Z.; Mortazavian, A.M. Wheat bread: Potential approach to fortify its lysine content. Curr. Nutr. Food Sci. 2019, 15, 630–637. [Google Scholar] [CrossRef]

- Souza, S.V.; Borges, N.; Vieira, E.F. Vitamin d-fortified bread: Systematic review of fortification approaches and clinical studies. Food Chem. 2022, 372, 131325. [Google Scholar] [CrossRef] [PubMed]

- Garrod, M.G.; Buchholz, B.A.; Miller, J.W.; Haack, K.W.; Green, R.; Allen, L.H. Vitamin B12 added as a fortificant to flour retains high bioavailability when baked in bread. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 438, 136–140. [Google Scholar] [CrossRef]

- Alsuhaibani, A.M. Rheological and nutritional properties and sensory evaluation of bread fortified with natural sources of calcium. J. Food Qual. 2018, 2018, 8308361. [Google Scholar] [CrossRef]

- Krochmal-Marczak, B.; Tobiasz-Salach, R.; Kaszuba, J. The effect of adding oat flour on the nutritional and sensory quality of wheat bread. Br. Food J. 2020, 122, 2329–2339. [Google Scholar] [CrossRef]

- Sajdakowska, M.; Gębski, J.; Jeżewska-Zychowicz, M.; Królak, M. Consumer choices in the bread market: The importance of fiber in consumer decisions. Nutrients 2020, 13, 132. [Google Scholar] [CrossRef]

- Ibrahim, U.K.; Salleh, R.M.; Maqsood-ul-Haque, S.N.S. Bread towards functional food: An overview. Int. J. Food Eng. 2015, 1, 39–43. [Google Scholar] [CrossRef][Green Version]

- Dziki, D.; Różyło, R.; Gawlik-Dziki, U.; Świeca, M. Current trends in the enhancement of antioxidant activity of wheat bread by the addition of plant materials rich in phenolic compounds. Trends Food Sci. Technol. 2014, 40, 48–61. [Google Scholar] [CrossRef]

- Odunlade, T.V.; Famuwagun, A.A.; Taiwo, K.A.; Gbadamosi, S.O.; Oyedele, D.J.; Adebooye, O.C. Chemical composition and quality characteristics of wheat bread supplemented with leafy vegetable powders. J. Food Qual. 2017, 2017, 9536716. [Google Scholar] [CrossRef]

- Klopsch, R.; Baldermann, S.; Hanschen, F.S.; Voss, A.; Rohn, S.; Schreiner, M.; Neugart, S. Brassica-enriched wheat bread: Unraveling the impact of ontogeny and breadmaking on bioactive secondary plant metabolites of pak choi and kale. Food Chem. 2019, 295, 412–422. [Google Scholar] [CrossRef] [PubMed]

- El-Gammal, R.E.; Ghoneim, G.A.; ElShehawy, S.M. Effect of moringa leaves powder (Moringa oleifera) on some chemical and physical properties of pan bread. J. Food Dairy Sci. 2016, 7, 307–314. [Google Scholar] [CrossRef]

- Man, S.M.; Păucean, A.; Chiş, M.S.; Muste, S.; Pop, A.; Mureşan, A.E.; Marțiş, G. Effect of nettle leaves powder (Urtica dioica L.) addition on the quality of bread. Hop Med. Plants 2019, 27, 104–112. [Google Scholar]

- Gawlik-Dziki, U.; Dziki, D.; Świeca, M.; Sęczyk, Ł.; Różyło, R.; Szymanowska, U. Bread enriched with Chenopodium quinoa leaves powder—The procedures for assessing the fortification efficiency. LWT 2015, 62, 1226–1234. [Google Scholar] [CrossRef]

- Pycia, K.; Pawłowska, A.M.; Kaszuba, J.; Żurek, N. Walnut Male Flowers (Juglans regia L.) as a Functional Addition to Wheat Bread. Foods 2022, 11, 3988. [Google Scholar] [CrossRef] [PubMed]

- Schwindl, S.; Kraus, B.; Heilmann, J. Phytochemical study of Juglans regia L. leaves. Phytochemistry 2017, 144, 58–70. [Google Scholar] [CrossRef] [PubMed]

- Elouafy, Y.; El Yadini, A.; Mortada, S.; Hnini, M.; Harhar, H.; Khalid, A.; Tabyaoui, M. Antioxidant, antimicrobial, and α-glucosidase inhibitory activities of saponin extracts from walnut (Juglans regia L.) leaves. Asian Pac. J. Trop. Biomed. 2023, 13, 60–69. [Google Scholar]

- Żurek, N.; Pycia, K.; Pawłowska, A.; Potocki, L.; Kapusta, I.T. Chemical profiling, bioactive properties, and anticancer and anti-microbial potential of Juglans regia L. leaves. Molecules 2023, 28, 1989. [Google Scholar] [CrossRef]

- Pereira, J.A.; Oliveira, I.; Sousa, A.; Valentão, P.; Andrade, P.B.; Ferreira, I.C.F.R.; Ferreres, F.; Bento, A.; Seabra, R.; Estevinho, L. Walnut (Juglans regia L.) leaves: Phenolic compounds, antibacterial activity and antioxidant potential of different cultivars. Food Chem. Toxicol. 2007, 45, 2287–2295. [Google Scholar] [CrossRef]

- Jakubczyk, T.; Haber, T. (Eds.) Analiza Zbóż i Przetworów Zbożowych, 2nd ed.; Wydawnictwo SGGW: Warszawa, Poland, 1983; pp. 268–278. (In Polish) [Google Scholar]

- AACC International. Guidelines for Measurement of Volume by Rapeseed Displacement. In AACC Approved Methods of Analysis, 11th ed.; Standard 10-05.01; AACC International: St. Paul, MN, USA, 2010. [Google Scholar]

- Bourekoua, H.; Rózyło, R.; Gawlik-Dziki, U.; Benatallah, L.; Zidoune, M.N.; Dziki, D. Evaluation of physical, sensorial, and antioxidant properties of gluten-free bread enriched with Moringa oleifera leaf powder. Eur. Food Res. Technol. 2017, 244, 189–195. [Google Scholar] [CrossRef]

- Dallmann, H. Porentabelle; 4. Auflage; Verlag Moritz-Schäfer: Detmold, Germany, 1981. [Google Scholar]

- Gao, X.; Ohlander, M.; Jeppsson, N.; Björk, L.; Trajkovski, V. Changes in antioxidant effects and their relationship to phytonutrients in fruits of sea buckthorn (Hippophae rhamnoides L.) during maturation. J. Agric. Food Chem. 2000, 48, 1485–1490. [Google Scholar] [CrossRef] [PubMed]

- Re, R.; Pellegrini, N.; Proteggente, A.; Pannala, A.; Yang, M.; Rice-Evans, C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic. Biol. Med. 1999, 26, 1231–1237. [Google Scholar] [CrossRef] [PubMed]

- Benzie, I.F.F.; Strain, J.J. The ferric reducing ability of plasma (FRAP) as a measure of antioxidant power: The FRAP assay. Anal. Biochem. 1996, 239, 70–76. [Google Scholar] [CrossRef]

- Gawlik-Dziki, U.; Świeca, M.; Dziki, D.; Sęczyk, Ł.; Złotek, U.; Różyło, R.; Kaszuba, K.; Ryszawy, D.; Czyż, J. Anticancer and antioxidant activity of bread enriched with broccoli sprouts. BioMed Res. Int. 2014, 2014, 608053. [Google Scholar] [CrossRef] [PubMed]

- García-Gómez, B.; Fernández-Canto, N.; Vázquez-Odériz, M.L.; Quiroga-García, M.; Munoz-Ferreiro, N.; Romero-Rodríguez, M.Á. Sensory descriptive analysis and hedonic consumer test for Galician type breads. Food Control 2022, 134, 108765. [Google Scholar] [CrossRef]

- Dziki, D.; Hassoon, W.H.; Biernacka, B.; Gawlik-Dziki, U. Dried and powdered leaves of parsley as a functional additive to wheat bread. Appl. Sci. 2022, 12, 7930. [Google Scholar] [CrossRef]

- Wang, J.; Rosell, C.M.; Benedito de Barber, C. Effect of the addition of different fibres on wheat dough performance and bread quality. Food Chem. 2002, 79, 221–226. [Google Scholar] [CrossRef]

- Krupa-Kozak, U.; Drabińska, N.; Bączek, N.; Šimková, K.; Starowicz, M.; Jeliński, T. Application of Broccoli Leaf Powder in Gluten-Free Bread: An Innovative Approach to Improve Its Bioactive Potential and Technological Quality. Foods 2021, 10, 819. [Google Scholar] [CrossRef] [PubMed]

- Baiano, A.; Viggiani, I.; Terracone, C.; Romaniello, R.; Nobile, M.D. Physical and sensory properties of bread enriched with phenolic aqueous extracts from vegetable wastes. Czech J. Food Sci. 2015, 33, 247–253. [Google Scholar] [CrossRef]

- Sivam, A.S.; Waterhouse, D.S.; Quek, S.; Perera, C.O. Properties of bread dough with added fiber polysaccharides and phenolic antioxidants: A review. J. Food Sci. 2010, 75, 163–174. [Google Scholar] [CrossRef]

- Adekunte, A.O.; Tiwari, B.K.; Cullen, P.J.; Scannell, A.G.M.; O’donnell, C.P. Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem. 2010, 122, 500–507. [Google Scholar] [CrossRef]

- Kohlmünzer, S. Folium Juglandis—Liść orzecha włoskiego. In Farmakognozja. Podręcznik Dla Studentów Farmacji, 5th ed.; Wydawnictwo Lekarskie PZWL: Warszawa, Poland, 1998; p. 25. (In Polish) [Google Scholar]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Sułek, A.; Kocira, S.; Biernacka, B. Effect of Moldavian dragonhead (Dracocephalum moldavica L.) leaves on the baking properties of wheat flour and quality of bread. CyTA-J. Food 2019, 17, 536–543. [Google Scholar] [CrossRef]

- Liu, L.Y.; Wu, K.L.; Jen, Y.W.; Yang, M.H. Effect of sweet potato leaf and stem addition on dough properties and bread quality. Food Sci. Technol. Int. 2007, 13, 239–244. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, H.; Mu, T. Effects of sweet potato leaf powder on sensory, texture, nutrition, and digestive characteristics of steamed bread. J. Food Process. Preserv. 2022, 46, e16697. [Google Scholar] [CrossRef]

- Amaral, J.S.; Seabra, R.M.; Andrade, P.B.; Valentão, P.; Pereira, J.A.; Ferreres, F. Phenolic profile in the quality control of walnut (Juglans regia L.) leaves. Food Chem. 2004, 88, 373–379. [Google Scholar] [CrossRef]

- Pycia, K.; Ivanišová, E. Physicochemical and antioxidant properties of wheat bread enriched with hazelnuts and walnuts. Foods 2020, 9, 1081. [Google Scholar] [CrossRef] [PubMed]

- Pycia, K.; Kapusta, I. Wpływ stopnia dojrzałości oraz wielkości dodatku orzechów laskowych i włoskich na właściwości fizyko-chemiczne i przeciwutleniajace wzbogaconego chleba pszennego. Żywn. Nauka. Technol. Jakość. 2020, 27, 62–81. (In Polish) [Google Scholar]

- Gawlik-Dziki, U.; Świeca, M.; Dziki, D.; Baraniak, B.; Tomiło, J.; Czyż, J. Quality and antioxidant properties of breads enriched with dry onion (Allium cepa L.) skin. Food Chem. 2013, 138, 1621–1628. [Google Scholar] [CrossRef]

- Cacak-Pietrzak, G.; Dziki, D.; Gawlik-Dziki, U.; Sułek, A.; Kalisz, S.; Sujka, K. Effect of the addition of dried dandelion roots (Taraxacum officinale F. H. Wigg.) on wheat dough and bread properties. Molecules 2021, 26, 7564. [Google Scholar] [CrossRef]

- Lee, J.S.; Kim, J.M. Quality characteristics and antioxidant properties of white pan bread added with sea buckthorn (Hippophae rhamnoids L.) berry powder. J. Korean Soc. Food Sci. Nutr. 2020, 33, 473–482. [Google Scholar]

- Taglieri, I.; Sanmartin, C.; Venturi, F.; Macaluso, M.; Bianchi, A.; Sgherri, C.; Quartacci, M.F.; De Leo, M.; Pistelli, L.; Palla, F.; et al. Bread fortified with cooked purple potato flour and citrus albedo: An evaluation of its compositional and sensorial properties. Foods 2021, 10, 942. [Google Scholar] [CrossRef] [PubMed]

- Mata-Ramírez, D.; Serna-Saldívar, S.O.; Villela-Castrejón, J.; Villaseñor-Durán, M.C.; Buitimea-Cantúa, N.E. Phytochemical profiles, dietary fiber and baking performance of wheat bread formulations supplemented with Roselle (Hibiscus sabdariffa). J. Food Meas. Charact. 2018, 12, 2657–2665. [Google Scholar] [CrossRef]

- Ross, C.F.; Hoye, C., Jr.; Fernandez-Plotka, V.C. Influence of heating on the polyphenolic content and antioxidant activity of grape seed flour. J. Food Sci. 2011, 76, C884–C890. [Google Scholar] [CrossRef] [PubMed]

- Blanch, G.P.; Ruiz Del Castillo, M.L. Effect of baking temperature on the phenolic content and antioxidant activity of black corn (Zea mays L.) bread. Foods 2021, 10, 1202. [Google Scholar] [CrossRef] [PubMed]

- Gil, J.V.; Esteban-Muñoz, A.; Fernández-Espinar, M.T. Changes in the polyphenolic profile and antioxidant activity of wheat bread after incorporating quinoa flour. Antioxidants 2021, 11, 33. [Google Scholar] [CrossRef] [PubMed]

- Meral, R.; Kose, Y.E. The effect of bread-making process on the antioxidant activity and phenolic profile of enriched breads. Qual. Assur. Saf. Crops Foods 2019, 11, 171–181. [Google Scholar] [CrossRef]

- Hanuka Katz, I.; Eran Nagar, E.; Okun, Z.; Shpigelman, A. The link between polyphenol structure, antioxidant capacity and shelf-life stability in the presence of fructose and ascorbic acid. Molecules 2020, 25, 225. [Google Scholar] [CrossRef]

- Das, L.; Raychaudhuri, U.; Chakraborty, R. Supplementation of common white bread by coriander leaf powder. Food Sci. Biotechnol. 2012, 21, 425–433. [Google Scholar] [CrossRef]

- Mohammed, A.M.; El-Anany, A.M.; Althwab, S.A.; Alhomaid, R.M.; Alharbi, H.F.; ALgheshairy, R.M.; Ali, R.F. Nutritional and quality attributes of bread fortified with cheeseweed mallow leaves powder. Nutr. Food Sci. 2023, 53, 1045–1058. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).