Improved Adhesion and Tribological Properties of AlTiN-TiSiN Coatings Deposited by DCMS and HiPIMS on Nitrided Tool Steels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reference Substrates

2.2. Film Deposition Techniques

2.3. Thickness, Structural Properties, and Profile Composition

2.4. Mechanical and Tribological Tests

3. Results

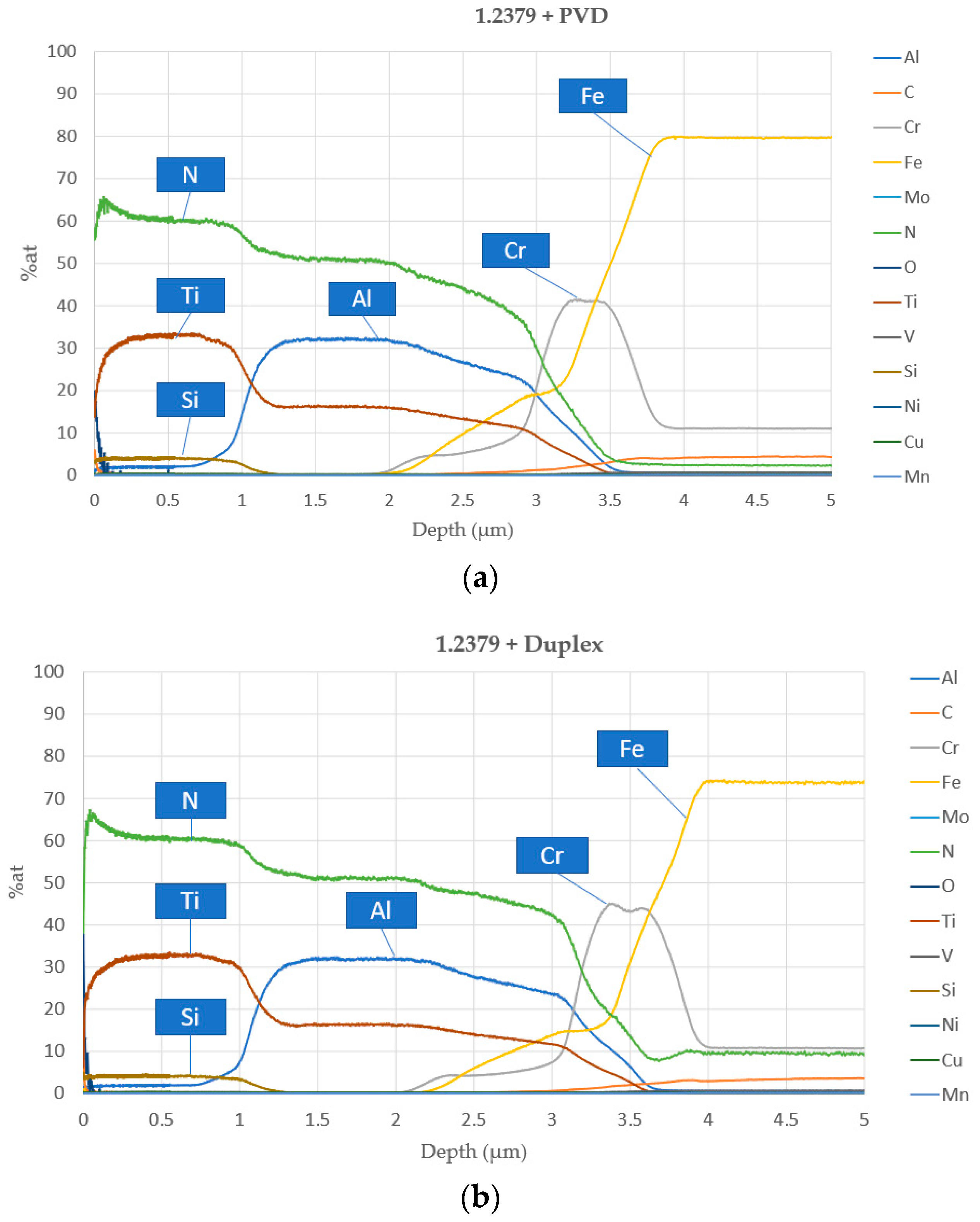

3.1. Thickness, Structural Properties, and Profile Composition

- Anchoring layer;

- Middle layer; and

- Outer layer.

3.2. Ultra-Microhardness Tests

3.3. Adhesion Tests

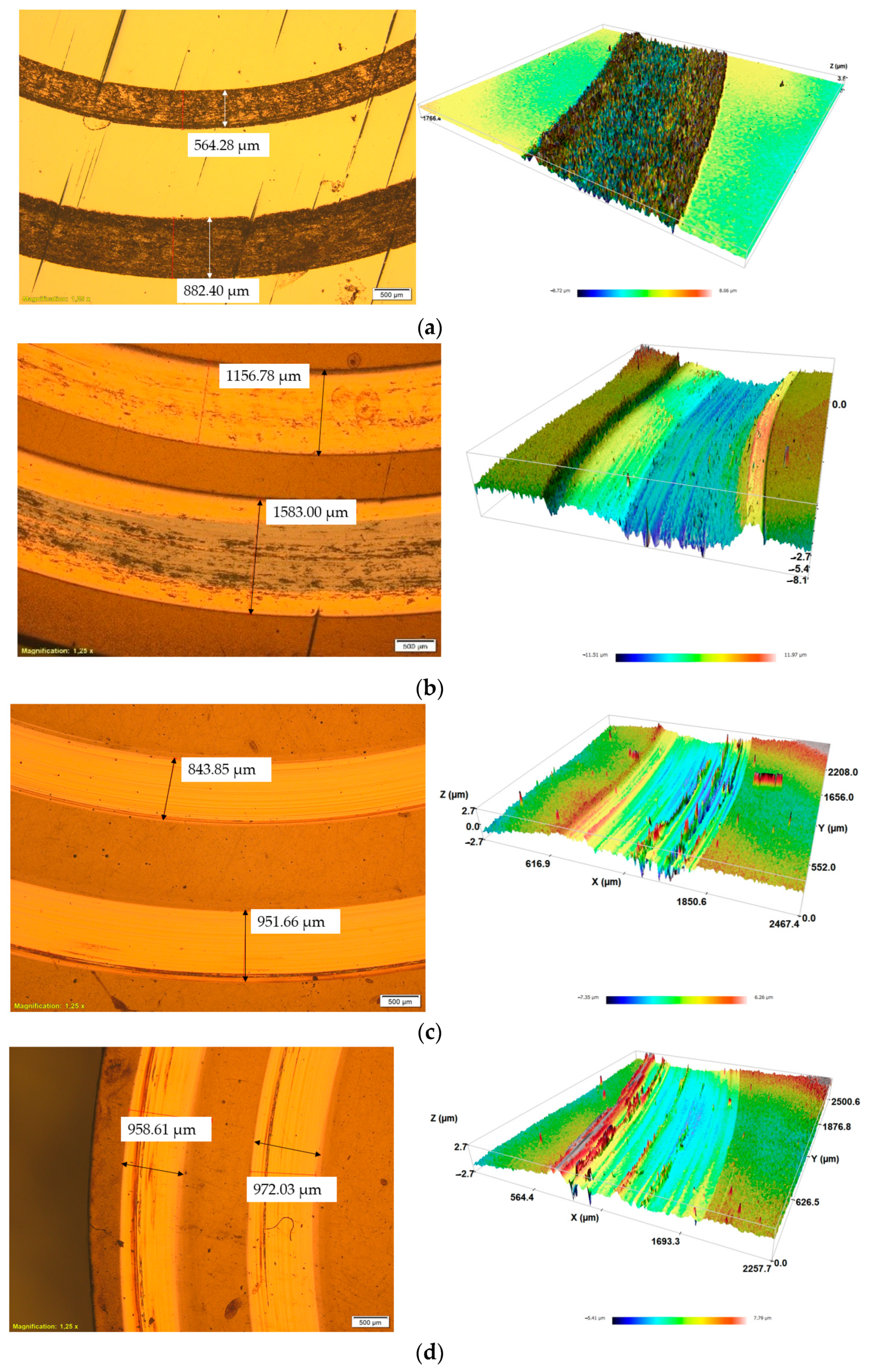

3.4. Friction and Wear Tests

4. Discussion

5. Conclusions

- The ultra-microhardness of the coatings was about 8.5–10 GPa for all the coated samples, with the higher values obtained for the duplex ones.

- Coefficient of friction (COF) values of around 0.65 were shown by all the specimens, something that can be explained because this coating is not a tribological coating but a hard coating.

- Duplex-coated samples presented greater toughness than the non-nitrided PVD-coated sample, since the HU3/Er2 ratio, which is associated with the resistance to plastic deformation, and CPR, which is related to the resistance to crack propagation, values are higher for those samples. This is correlated with a greater resistance to wear of those samples, which is a sign that hardness is not the only important parameter in determining the wear behavior of coatings.

- The coatings improved the wear resistance of the substrate considerably, though the best results were obtained for the duplex-coated samples.

- The coatings showed a great adhesion to the substrate, with Lc2 values up to 75 N for the PVD-coated sample and 96 N and 109 N for the duplex-treated 1.2379 and Vanadis 4 samples, respectively. This shows that the combination of the nitriding process with the bonding layer deposited by HiPIMS and the DCMS-deposited layers improves the adhesion properties of these coatings.

- Differences between the different substrates were observed, with greater adhesive and mechanical properties shown by the powder metallurgical steel compared with the conventional steel. This could be because of the higher quality of these steels.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Deng, Y.; Tan, C.; Wang, Y.; Chen, L.; Cai, P.; Kuang, T.; Lei, S.; Zhou, K. Effects of tailored nitriding layers on comprehensive properties of duplex plasma-treated AlTiN coatings. Ceram. Int. 2017, 43, 8721–8729. [Google Scholar] [CrossRef]

- Musil, J. Hard and superhard nanocomposite coatings. Surf. Coat. Technol. 2000, 125, 322–330. [Google Scholar] [CrossRef]

- Lousa, A.; Romero, J.; Martínez, E.; Esteve, J.; Montalà, F.; Carreras, L. Multilayered chromium/chromium nitride coatings for use in pressure die-casting. Surf. Coat. Technol. 2001, 146–147, 268–273. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, J.; Meng, X.; Kwon, S.; Zhang, S. Investigation on microstructures and mechanical properties of AlCrN coatings deposited on the surface of plasma nitrocarburized cool-work tool steels. Vacuum 2015, 121, 194–201. [Google Scholar] [CrossRef]

- Gilewicz, A.; Jedrzejewski, R.; Myslinski, P.; Warcholinski, B. Structure, Morphology, and Mechanical Properties of AlCrN Coatings Deposited by Cathodic Arc Evaporation. J. Mater. Eng. Perform. 2019, 28, 1522–1531. [Google Scholar] [CrossRef] [Green Version]

- Ramírez-Reyna, F.O.; Rodríguez-Castro, G.A.; Figueroa-López, U.; Morón, R.C.; Arzate-Vázquez, I.; Meneses-Amador, A. Effect of nitriding pretreatment on adhesion and tribological properties of AlCrN coating. Mater. Lett. 2021, 284, 128931. [Google Scholar] [CrossRef]

- Geng, D.; Zeng, R.; Wu, Z.; Wang, Q. An investigation on microstructure and milling performance of arc-evaporated TiSin/AlTiN film. Thin Solid Film. 2020, 709, 138243. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Marchin, N.; Ashrafizadeh, F. Effect of carbon addition on tribological performance of TiSiN coatings produced by cathodic arc physical vapour deposition. Surf. Coat. Technol. 2021, 407, 126781. [Google Scholar] [CrossRef]

- Chim, Y.C.; Ding, X.Z.; Zeng, X.T.; Zhang, S. Oxidation resistance of TiN, CrN, TiAlN and CrAlN coatings deposited by lateral rotating cathode arc. Thin Solid Film. 2009, 517, 4845–4849. [Google Scholar] [CrossRef]

- Panjan, P.; Navinšek, B.; Cvelbar, A.; Zalar, A.; Milošev, I. Oxidation of TiN, ZrN, TiZrN, CrN, TiCrN and TiN/CrN multilayer hard coatings reactively sputtered at low temperature. Thin Solid Film. 1996, 281–282, 298–301. [Google Scholar] [CrossRef]

- Sreejith, P.S.; Ngoi, B.K.A. Dry machining: Machining of the future. J. Mater. Process. Technol. 2000, 101, 287–291. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Koseki, S.; Inoue, K.; Morito, S.; Ohba, T.; Usuki, H. Comparison of TiN-coated tools using CVD and PVD processes during continuous cutting of Ni-based superalloys. Surf. Coat. Technol. 2015, 283, 353–363. [Google Scholar] [CrossRef]

- Peng, Y.H.; Chen, L.; Xu, Y.X.; Hu, C.; Du, Y. Interface enhanced mechanical and thermal properties of TiSiN/TiAlN multilayers. J. Alloys Compd. 2021, 861, 158571. [Google Scholar] [CrossRef]

- Ichimura, H.; Kawana, A. High-temperature oxidation of ion-plated TiN and TiAlN films. J. Mater. Res. 1993, 8, 1093–1100. [Google Scholar] [CrossRef]

- Wiesing, M.; de los Arcos, T.; Grundmeier, G. The Thermal Oxidation of TiAlN High Power Pulsed Magnetron Sputtering Hard Coatings as Revealed by Combined Ion and Electron Spectroscopy. Adv. Mater. Interfaces 2017, 4, 1600861. [Google Scholar] [CrossRef]

- McIntyre, D.; Greene, J.E.; Håkansson, G.; Sundgren, J.E.; Münz, W.D. Oxidation of metastable single-phase polycrystalline Ti 0.5Al0.5N films: Kinetics and mechanisms. J. Appl. Phys. 1990, 67, 1542–1553. [Google Scholar] [CrossRef]

- Wu, Z.T.; Sun, P.; Qi, Z.B.; Wei, B.B.; Wang, Z.C. High temperature oxidation behavior and wear resistance of Ti0.53Al0.47N coating by cathodic arc evaporation. Vacuum 2017, 135, 34–43. [Google Scholar] [CrossRef]

- Qi, Z.B.; Sun, P.; Zhu, F.P.; Wu, Z.T.; Liu, B.; Wang, Z.C.; Peng, D.L.; Wu, C.H. Relationship between tribological properties and oxidation behavior of Ti0.34Al0.66N coatings at elevated temperature up to 900 °C. Surf. Coat. Technol. 2013, 231, 267–272. [Google Scholar] [CrossRef]

- Ma, H.; Miao, Q.; Zhang, G.; Liang, W.; Wang, Y.; Sun, Z.; Lin, H. The influence of multilayer structure on mechanical behavior of TiN/TiAlSiN multilayer coating. Ceram. Int. 2021, 47, 12583–12591. [Google Scholar] [CrossRef]

- Lü, W.; Li, G.; Zhou, Y.; Liu, S.; Wang, K.; Wang, Q. Effect of high hardness and adhesion of gradient TiAlSiN coating on cutting performance of titanium alloy. J. Alloys Compd. 2020, 820, 153137. [Google Scholar] [CrossRef]

- Li, G.; Sun, J.; Xu, Y.; Xu, Y.; Gu, J.; Wang, L.; Huang, K.; Liu, K.; Li, L. Microstructure, mechanical properties, and cutting performance of TiAlSiN multilayer coatings prepared by HiPIMS. Surf. Coat. Technol. 2018, 353, 274–281. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.L.; Chen, W.C.; Tsai, P.C.; Ho, W.Y.; Wang, D.Y. Characteristics and performance of TiSiN/TiAlN multilayers coating synthesized by cathodic arc plasma evaporation. Surf. Coat. Technol. 2007, 202, 987–992. [Google Scholar] [CrossRef]

- Yu, D.; Wang, C.; Cheng, X.; Zhang, F. Microstructure and properties of TiAlSiN coatings prepared by hybrid PVD technology. Thin Solid Film. 2009, 517, 4950–4955. [Google Scholar] [CrossRef]

- Chen, L.; Xu, Y.X.; Du, Y.; Liu, Y. Effect of bilayer period on structure, mechanical and thermal properties of TiAlN/AlTiN multilayer coatings. Thin Solid Film. 2015, 592, 207–214. [Google Scholar] [CrossRef]

- Chen, L.; Wang, S.Q.; Du, Y.; Zhou, S.Z.; Gang, T.; Fen, J.C.; Chang, K.K.; Li, Y.W.; Xiong, X. Machining performance of Ti-Al-Si-N coated inserts. Surf. Coat. Technol. 2010, 205, 582–586. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Kuang, T.; Li, Y.; Ma, W. Novel performances of in situ plasma nitriding-PVD duplex-treated nanocrystalline TiN coatings. Surf. Eng. 2018, 34, 520–526. [Google Scholar] [CrossRef]

- Lee, S.Y. Mechanical properties of TiNx/Cr1-xN thin films on plasma nitriding-assisted AISI H13 steel. Surf. Coat. Technol. 2005, 193, 55–59. [Google Scholar] [CrossRef]

- Hoy, R.; Kamminga, J.D.; Janssen, G.C.A.M. Scratch resistance of CrN coatings on nitrided steel. Surf. Coat. Technol. 2006, 200, 3856–3860. [Google Scholar] [CrossRef]

- Khlifi, K.; Ben Cheikh Larbi, A. Investigation of adhesion of PVD coatings using various approaches. Surf. Eng. 2013, 29, 555–560. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Prakash, M.S.; Jain, A.; Rajam, K.S. Structure, hardness and thermal stability of TiAlN and nanolayered TiAlN/CrN multilayer films. Vacuum 2005, 77, 169–179. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Rajam, K.S. Raman spectroscopy studies on the thermal stability of TiN, CrN, TiAIN coatings and nanolayered TiN/CrN, TiAIN/CrN multilayer coatings. J. Mater. Res. 2004, 19, 3196–3205. [Google Scholar] [CrossRef]

- Kang, G.H.; Uchida, H.; Koh, E.S. A study on the surface structure of Ti cathode and the macroparticle of TiN films prepared by the arc ion plating process. Surf. Coat. Technol. 1996, 86–87, 421–424. [Google Scholar] [CrossRef]

- Ljungcrantz, H.; Hultman, L.; Sundgren, J.E.; Håkansson, G.; Karlsson, L. Microstructural investigation of droplets in arc-evaporated TiN films. Surf. Coat. Technol. 1994, 63, 123–128. [Google Scholar] [CrossRef]

- Gui, B.; Zhou, H.; Zheng, J.; Liu, X.; Feng, X.; Zhang, Y.; Yang, L. Microstructure and properties of TiAlCrN ceramic coatings deposited by hybrid HiPIMS/DC magnetron co-sputtering. Ceram. Int. 2020, 47, 8175–8183. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Z.; Xu, Y.X.; Wang, Q.; Chen, L.; Kim, K.H. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition. Surf. Coat. Technol. 2019, 378, 125022. [Google Scholar] [CrossRef]

- Bell, T.; Dong, H.; Sun, Y. Realising the potential of duplex surface engineering. Tribol. Int. 1998, 31, 127–137. [Google Scholar] [CrossRef]

- Das, K.; Alphonsa, J.; Ghosh, M.; Ghanshyam, J.; Rane, R.; Mukherjee, S. Influence of pretreatment on surface behavior of duplex plasma treated AISI H13 tool steel. Surf. Interfaces 2017, 8, 206–213. [Google Scholar] [CrossRef]

- Zeghni, A.E.; Hashmi, M.S.J. The effect of coating and nitriding on the wear behaviour of tool steels. J. Mater. Process. Technol. 2004, 155–156, 1918–1922. [Google Scholar] [CrossRef]

- Zheng, J.; Zhang, S.H.; Wu, P.; Kwon, S.C.; Li, M.X.; Liu, S.Y.; Chen, W.L. Microstructures and mechanical properties of duplex-treated composite ceramic coatings with and without compound layer. Ceram. Int. 2015, 41, 2519–2526. [Google Scholar] [CrossRef]

- Yang, S.; Cooke, K.; Sun, H.; Li, X.; Lin, K.; Dong, H. Development of advanced duplex surface systems by combining CrAlN multilayer coatings with plasma nitrided steel substrates. Surf. Coat. Technol. 2013, 236, 2–7. [Google Scholar] [CrossRef]

- Björk, T.; Westergård, R.; Hogmark, S.; Bergström, J.; Hedenqvist, P. Physical vapour deposition duplex coatings for aluminium extrusion dies. Wear 1999, 225–229, 1123–1130. [Google Scholar] [CrossRef]

- Dong, H.; Sun, Y.; Bell, T. Enhanced corrosion resistance of duplex coatings. Surf. Coat. Technol. 1997, 90, 91–101. [Google Scholar] [CrossRef]

- Harris, S.G.; Doyle, E.D.; Vlasveld, A.C.; Dolder, P.J. Dry cutting performance of partially filtered arc deposition titanium aluminium nitride coatings with various metal nitride base coatings. Surf. Coat. Technol. 2001, 146–147, 305–311. [Google Scholar] [CrossRef]

- Podgornik, B.; Vižintin, J.; Wänstrand, O.; Larsson, M.; Hogmark, S.; Ronkainen, H.; Holmberg, K. Tribology properties of plasma nitrided and hard coated AISI 4140 steel. Wear 2001, 249, 254–259. [Google Scholar] [CrossRef]

- Torres, R.D.; Soares, P.C.; Schmitz, C.; Siqueira, C.J.M. Influence of the nitriding and TiAlN/TiN coating thickness on the sliding wear behavior of duplex treated AISI H13 steel. Surf. Coat. Technol. 2010, 205, 1381–1385. [Google Scholar] [CrossRef]

- Tillmann, W.; Grisales, D.; Stangier, D. Effects of AISI H11 surface integrity on the residual stresses and adhesion of TiAlN/substrate compounds. Surf. Coat. Technol. 2019, 357, 466–472. [Google Scholar] [CrossRef]

- Tillmann, W.; Vogli, E.; Momeni, S. Improvement of press dies used for the production of diamond composites by means of DUPLEX-PVD-coatings. Surf. Coat. Technol. 2010, 205, 1571–1577. [Google Scholar] [CrossRef]

- Sprute, T.; Tillmann, W.; Grisales, D.; Selvadurai, U.; Fischer, G. Influence of substrate pre-treatments on residual stresses and tribo-mechanical properties of TiAlN-based PVD coatings. Surf. Coat. Technol. 2014, 260, 369–379. [Google Scholar] [CrossRef]

- Park, B.; Jung, D.H.; Kim, H.; Yoo, K.C.; Lee, J.J.; Joo, J. Adhesion properties of TiB2 coatings on nitrided AISI H13 steel. Surf. Coat. Technol. 2005, 200, 726–729. [Google Scholar] [CrossRef]

- Claver, A.; Jiménez-Piqué, E.; Palacio, J.F.; Almandoz, E.; Fernández de Ara, J.; Fernández, I.; Santiago, J.A.; Barba, E.; García, J.A. Comparative Study of Tribomechanical Properties of HiPIMS with Positive Pulses DLC Coatings on Different Tools Steels. Coatings 2020, 11, 28. [Google Scholar] [CrossRef]

- Akhter, R.; Zhou, Z.; Xie, Z.; Munroe, P. Enhancing the adhesion strength and wear resistance of nanostructured NiCrN coatings. Appl. Surf. Sci. 2021, 541, 148533. [Google Scholar] [CrossRef]

- Chen, W.; Fang, B.; Zhang, D.; Meng, X.; Zhang, S. Thermal stability and mechanical properties of HVOF/PVD duplex ceramic coatings produced by HVOF and cathodic vacuum arc. Ceram. Int. 2017, 43, 7415–7423. [Google Scholar] [CrossRef]

- Toboła, D.; Brostow, W.; Czechowski, K.; Rusek, P. Improvement of wear resistance of some cold working tool steels. Wear 2017, 382–383, 29–39. [Google Scholar] [CrossRef]

- García, J.A.; Rodríguez, R.J.; Martínez, R.; Fernández, C.; Fernández, A.; Payling, R. Depth profiling of industrial surface treatments by rf and dc glow discharge spectrometry. Appl. Surf. Sci. 2004, 235, 97–102. [Google Scholar] [CrossRef]

- Chen, W.; Zheng, J.; Lin, Y.; Kwon, S.; Zhang, S. Comparison of AlCrN and AlCrTiSiN coatings deposited on the surface of plasma nitrocarburized high carbon steels. Appl. Surf. Sci. 2015, 332, 525–532. [Google Scholar] [CrossRef]

- ASTM International. G99—17 Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus; ASTM International: West Conshohocken, PA, USA, 2017; Available online: https://www.astm.org (accessed on 23 September 2021).

- Charitidis, C.A. Nanomechanical and nanotribological properties of carbon-based thin films: A review. Int. J. Refract. Met. Hard Mater. 2010, 28, 51–70. [Google Scholar] [CrossRef]

- Galvan, D.; Pei, Y.T.; De Hosson, J.T.M. Deformation and failure mechanism of nano-composite coatings under nano-indentation. Surf. Coat. Technol. 2006, 200, 6718–6726. [Google Scholar] [CrossRef] [Green Version]

- Sha, C.; Zhou, Z.; Xie, Z.; Munroe, P. Scratch response and tribological behaviour of CrAlNiN coatings deposited by closed field unbalanced magnetron sputtering system. Surf. Coat. Technol. 2019, 367, 30–40. [Google Scholar] [CrossRef]

- Leyland, A.; Matthews, A. On the significance of the H/E ratio in wear control: A nanocomposite coating approach to optimised tribological behaviour. Wear 2000, 246, 1–11. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Effect of sputtering target power on microstructure and mechanical properties of nanocomposite nc-TiN/a-SiNx thin films. Thin Solid Film. 2004, 447–448, 462–467. [Google Scholar] [CrossRef]

- He, J.; Lan, X.; Wan, J.; Liu, H.; Liu, Z.; Jiao, D.; Zhong, X.; Cheng, Y.; Qiu, W. Modifying Cr/CrN composite structure by Fe addition: Toward manufacturing cost-effective and tough hard coatings. Appl. Surf. Sci. 2021, 545, 149025. [Google Scholar] [CrossRef]

- Cai, F.; Zhang, S.; Li, J.; Chen, Z.; Li, M.; Wang, L. Effect of nitrogen partial pressure on Al-Ti-N films deposited by arc ion plating. Appl. Surf. Sci. 2011, 258, 1819–1825. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D. Structure and properties of AlCrN coatings deposited using cathodic arc evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Al-Bukhaiti, M.A.; Al-Hatab, K.A.; Tillmann, W.; Hoffmann, F.; Sprute, T. Tribological and mechanical properties of Ti/TiAlN/TiAlCN nanoscale multilayer PVD coatings deposited on AISI H11 hot work tool steel. Appl. Surf. Sci. 2014, 318, 180–190. [Google Scholar] [CrossRef]

- Kumar, S.; Maity, S.R.; Patnaik, L. Friction and tribological behavior of bare nitrided, TiAlN and AlCrN coated MDC-K hot work tool steel. Ceram. Int. 2020, 46, 17280–17294. [Google Scholar] [CrossRef]

- Myśliński, P.; Szparaga, Ł.; Gilewicz, A.; Mydłowska, K.; Piątkowska, A. Investigations of the thermo-mechanical stability of hybrid layers for tribological applications: Nitrided layer/CrCN coating system. Vacuum 2018, 148, 276–285. [Google Scholar] [CrossRef]

- Candido Recco, A.A.; Tschiptschin, A.P. Structural and mechanical characterization of duplex multilayer coatings deposited onto H13 tool steel. J. Mater. Res. Technol. 2012, 1, 182–188. [Google Scholar] [CrossRef] [Green Version]

- Kumar, C.S.; Patel, S.K. Performance analysis and comparative assessment of nano-composite TiAlSiN/TiSiN/TiAlN coating in hard turning of AISI 52100 steel. Surf. Coat. Technol. 2018, 335, 265–279. [Google Scholar] [CrossRef]

- Tan, C.; Kuang, T.; Zhou, K.; Zhu, H.; Deng, Y.; Li, X.; Cai, P.; Liu, Z. Fabrication and characterization of in-situ duplex plasma-treated nanocrystalline Ti/AlTiN coatings. Ceram. Int. 2016, 42, 10793–10800. [Google Scholar] [CrossRef]

- Novák, P.; Vojtěch, D.; Šerák, J. Wear and corrosion resistance of a plasma-nitrided PM tool steel alloyed with niobium. Surf. Coat. Technol. 2006, 200, 5229–5236. [Google Scholar] [CrossRef]

- Kabir, M.S.; Munroe, P.; Zhou, Z.; Xie, Z. Scratch adhesion and tribological behaviour of graded Cr/CrN/CrTiN coatings synthesized by closed-field unbalanced magnetron sputtering. Wear 2017, 380–381, 163–175. [Google Scholar] [CrossRef]

| Steel | C (%) | Si (%) | Cr (%) | V (%) | Mn (%) | Mo (%) |

|---|---|---|---|---|---|---|

| 1.2379 | 1.25 | 0.25 | 12 | 0.95 | 0.4 | 0.80 |

| Vanadis 4 | 1.4 | 0.4 | 4.7 | 3.7 | 0.4 | 3.5 |

| Sequence of Operations in the PVD Coating Deposition Process and the Parameters |

|---|

| Vacuum |

| A base pressure of 3 mPa is achieved with the use of turbomolecular pumps and double-stage rotary paddles |

| Heating |

| Heating process with two groups of resistors at 10,000 W and 8000 W. T: 480 °C. Minimum vacuum: 4 mPa Total heating time: 1.5 h |

| Ion Etching (MF-Electron Anode) |

| Heating: 3500 W Cycles of 30 min |

| Bonding Layer HiPIMS |

| HiPIMS 1 Cr Cathode. Power: 2500–3500 W-V HiPIMS Medium frequency. Pulsed Voltage Gas: Ar. Total pressure: 350 mPa |

| COATING |

| Phase 1 (TiAlN) |

| T: 480 °C. Total Pressure: 650 mPa. Gases: N2, Ar. Cathodes: Ti/Al. Power: 9.5 KW. Cathodes: Ti/SI. Power: 0.5 KW DC Table: 90 V, Coating Time: 2400 seg. |

| Phase 3 (TiAlSiN) |

| T: 480 °C. Total pressure: 650 mPa. Gases: N2, Ar. Cathodes Ti/Al: power ramp from 9.5 KW to 500 W, Cathodes Ti/Si: ramp from 0.5 KW to 6 KW DC: 110 V, Coating time: 3000 s |

| Cooling |

| Up to 180 °C in a vacuum |

| Sample | Total Thickness (µm) | Outer Layer (µm) | Middle Layer (µm) | Anchoring Layer (µm) |

|---|---|---|---|---|

| 1.2379 + PVD | 5.01 ± 0.03 | 1.70 ± 0.03 | 2.70 ± 0.01 | 0.60 ± 0.00 |

| 1.2379 + Duplex | 5.14 ± 0.06 | 1.65 ± 0.07 | 2.94 ± 0.04 | 0.55 ± 0.04 |

| Vanadis 4 + Duplex | 5.22 ± 0.01 | 1.65 ± 0.01 | 2.97 ± 0.02 | 0.60 ± 0.04 |

| Parameter | Uncoated 1.2379 | 1.2379 + PVD | Duplex 1.2379 | Duplex Vanadis 4 |

|---|---|---|---|---|

| HU (GPa) | 6.4 ± 0.4 | 9.3 ± 0.4 | 9.7 ± 0.4 | 10.3 ± 0.3 |

| Er (Gpa) | 235 ± 3 | 299 ± 3 | 306 ± 4 | 328 ± 4 |

| % We | 31% | 37% | 39% | 40% |

| Plastic Hardness (GPa) | 9.8 ± 0.1 | 16.3 ± 0.1 | 17.4 ± 0.1 | 18.8 ± 0.1 |

| Maximum hardness (GPa) | 6.4 ± 0.3 | 11.1 ± 0.4 | 11.2 ± 0.6 | 11.6 ± 0.7 |

| HU/Er | 0.0272 | 0.0309 | 0.0313 | 0.0314 |

| HU3/Er2 (GPa) | 0.0047 | 0.0088 | 0.0095 | 0.0102 |

| Parameter | Uncoated 1.2379 | 1.2379 + PVD | Duplex 1.2379 | Duplex Vanadis 4 |

|---|---|---|---|---|

| HU (GPa) | 6.5 ± 0.7 | 8.5 ± 0.4 | 8.9 ± 0.7 | 9.7 ± 0.2 |

| Er (Gpa) | 248 ± 1 | 298 ± 1 | 308 ± 2 | 329 ± 1 |

| % We | 31% | 34% | 35% | 37% |

| Plastic Hardness (GPa) | 9.9 ± 0.1 | 13.9 ± 0.1 | 14.8 ± 0.1 | 16.7 ± 0.1 |

| Maximum hardness (GPa) | 6.8 ± 0.6 | 11.2 ± 0.4 | 11.2 ± 0.6 | 11.8 ± 0.6 |

| HU/Er | 0.0264 | 0.0285 | 0.0289 | 0.0295 |

| HU3/Er2 (GPa) | 0.0046 | 0.0069 | 0.0074 | 0.0084 |

| Sample | Lc1 (N) | Lc2 (N) | Lc3 (N) |

|---|---|---|---|

| 1.2379 + PVD | 46 | 75 | 85 |

| Duplex 1.2379 | 62 | 96 | 109 |

| Duplex Vanadis 4 | 48 | 109 | 116 |

| Sample | Friction Coefficient | Volume Loss (m3) ASTM G99 | Volume Loss (m3) Confocal |

|---|---|---|---|

| Uncoated 1.2379 * | 0.65 | (5.90 ± 4.36) × 10−10 | (2.81 ± 1.74) × 10−11 |

| 1.2379 + PVD | 0.645 | (5.03 ± 2.94) × 10−9 | (5.49 ± 0.52) × 10−10 |

| Duplex + 1.2379 | 0.65 | (1.86 ± 0.97) × 10−9 | (4.88 ± 1.67) × 10−11 |

| Duplex + Vanadis 4 | 0.69 | (1.81 ± 0.66) × 10−9 | (5.27 ± 3.00) × 10−11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Claver, A.; Randulfe, J.J.; Palacio, J.F.; Fernández de Ara, J.; Almandoz, E.; Montalá, F.; Colominas, C.; Cot, V.; García, J.A. Improved Adhesion and Tribological Properties of AlTiN-TiSiN Coatings Deposited by DCMS and HiPIMS on Nitrided Tool Steels. Coatings 2021, 11, 1175. https://doi.org/10.3390/coatings11101175

Claver A, Randulfe JJ, Palacio JF, Fernández de Ara J, Almandoz E, Montalá F, Colominas C, Cot V, García JA. Improved Adhesion and Tribological Properties of AlTiN-TiSiN Coatings Deposited by DCMS and HiPIMS on Nitrided Tool Steels. Coatings. 2021; 11(10):1175. https://doi.org/10.3390/coatings11101175

Chicago/Turabian StyleClaver, Adrián, Jesús J. Randulfe, José F. Palacio, Jonathan Fernández de Ara, Eluxka Almandoz, Francesc Montalá, Carles Colominas, Victor Cot, and Jose A. García. 2021. "Improved Adhesion and Tribological Properties of AlTiN-TiSiN Coatings Deposited by DCMS and HiPIMS on Nitrided Tool Steels" Coatings 11, no. 10: 1175. https://doi.org/10.3390/coatings11101175

APA StyleClaver, A., Randulfe, J. J., Palacio, J. F., Fernández de Ara, J., Almandoz, E., Montalá, F., Colominas, C., Cot, V., & García, J. A. (2021). Improved Adhesion and Tribological Properties of AlTiN-TiSiN Coatings Deposited by DCMS and HiPIMS on Nitrided Tool Steels. Coatings, 11(10), 1175. https://doi.org/10.3390/coatings11101175