Fire and Polymers (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Applications".

Viewed by 41498Editors

Interests: flame retardancy; thermal degradation; biobased flame retardants; biopolymers; aging of flame retardant and polymers; fiber-reinforced composites

Special Issues, Collections and Topics in MDPI journals

Interests: biodegradable polymers; biomaterials; materials science; polymer blends; poly-mer nanocomposites; waste management; polymer recycling; rubber recycling; green processing; sustainable polymers

Special Issues, Collections and Topics in MDPI journals

Interests: hybrid O/I systems; sol–gel processes; biomacromolecules; biopolymers; flame retardance; structure–property–processing relationships; thermal degradation; polymer (nano)composites

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

Research on flame retardancy of polymer systems as well as developing architecturally designed flame retardant polymers has experienced a tremendous upward trend in the last decade. In parallel with such ascending trend in the number of publications, it has been attempted by the national and international committees/organizations to define and implement into practice some new directives, legislations and rules to reduce consequences caused by fire. There is no denying that polymers are building blocks of constructions and structures, in both industrial and social media. For instance, nowadays, polymers as coatings, color, or decorative topcoat layers are used in tall buildings and towers thanks to their lightness, anti-corrosive nature, and decorative character. On the other hand, hazardous features of using polymers in leading fire from the surface of the structures to the bulk of buildings, where people live or are doing their job must be cared by developing innovative flame retardant polymer composites. To rely on this necessity, as well as to integrate research on this topic, Polymers as a prestigious journal working in the field of polymer science and technology, dedicated “Fire and Polymers” as a collection part.

The mission for this collection is to find and make directed the articles on the subject of innovative polymer-based flame retardant systems, which are being received by polymers, towards a scientific committee. The collection editors are specifically working on flame retardant polymers and fire retardancy of polymer composites, having a comprehensive view over the quality of works. This collection provides the readers and authors with an active and dynamic atmosphere to keep them updated about new progress in the field. Original regular papers, Review Papers, and Short Communications, are possible kinds of manuscript that can be submitted by authors.

Topics include, but are not limited to:

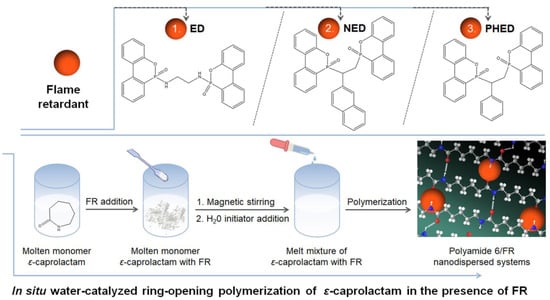

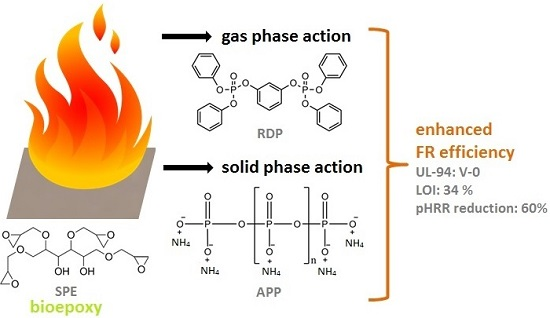

- Synthesis and design of flame retardant additives for polymers

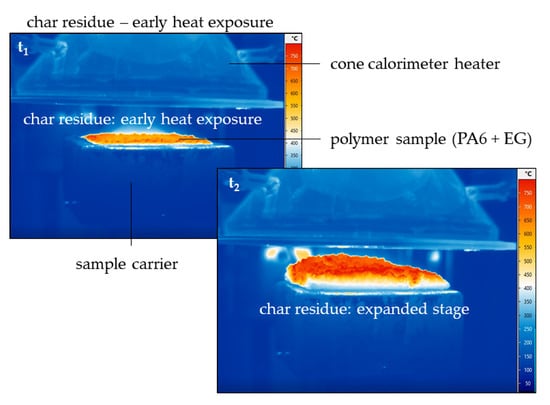

- Development and characterization of flame retardant polymer blends and composites

- Strategy for additive manufacturing for flame retardant polymers

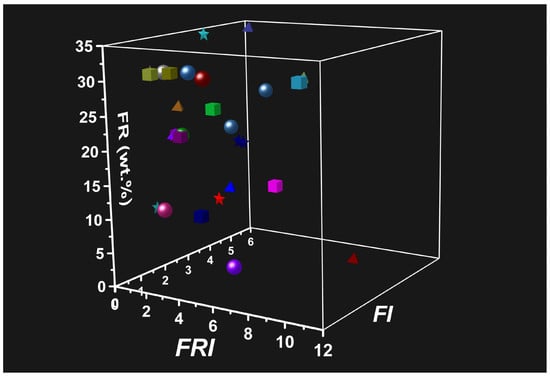

- Assessment of the performances of flame retardant polymers

- Environmental impact of flame retardant polymers

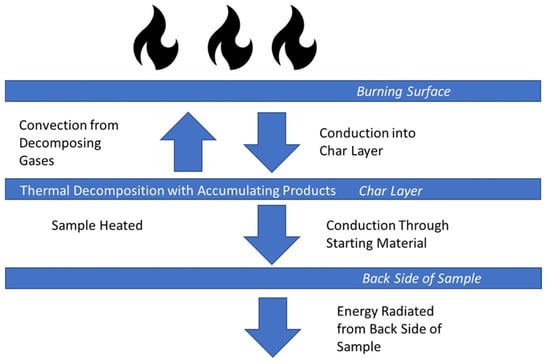

- Modelling and simulation of flame retardancy mechanism in polymer systems

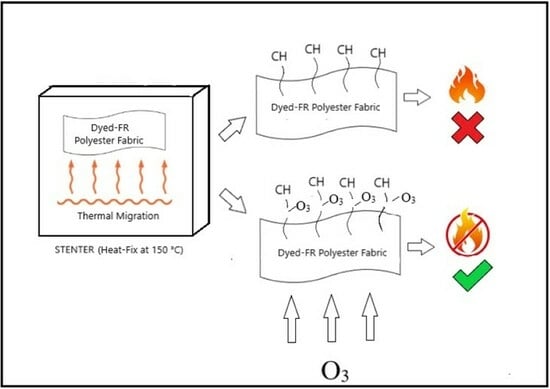

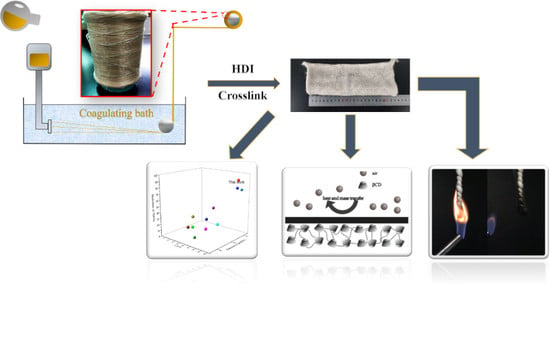

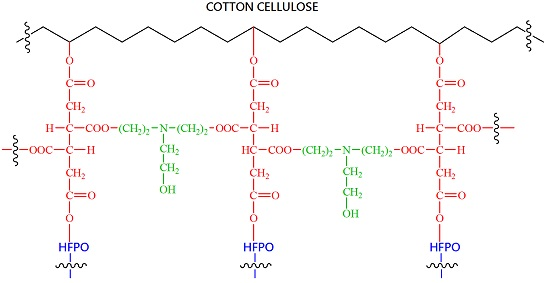

- Flame retardancy of polymeric fibers and textiles

- Recycling of flame retardant polymer composites

- Green flame retardant polymer composites

- Flame retardant polymer coatings and thin films

Dr. Henri Vahabi

Prof. Dr. Mohammad Reza Saeb

Prof. Dr. Giulio Malucelli

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- flame retardants

- polymers

- polymer composites

- polymer coatings and thin films

- fibers and fabrics

- nanocomposites

- fire resistance

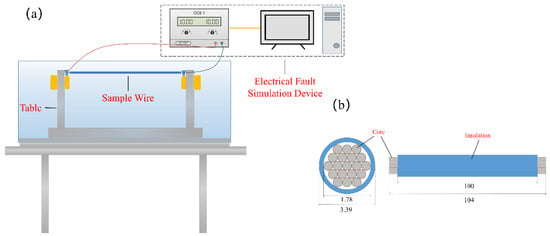

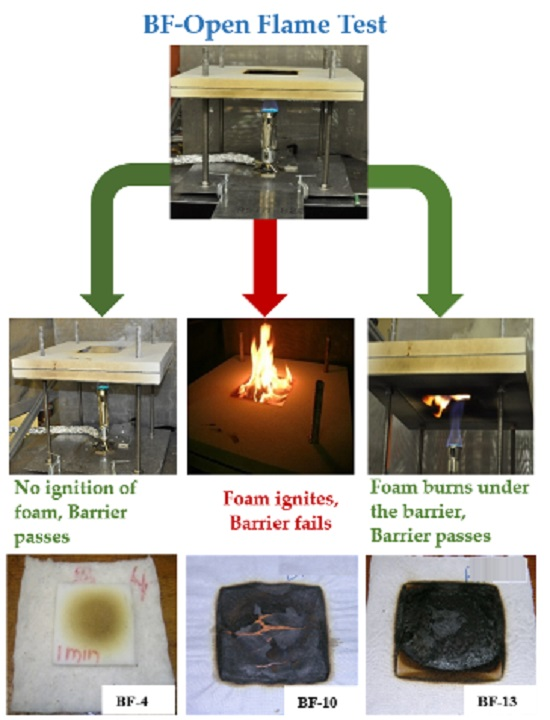

- fire testing

- fire modelling

- fire safety regulation

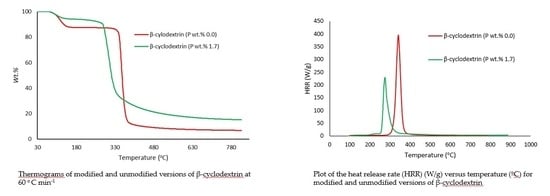

- heat release

- flame retardant ecological issues

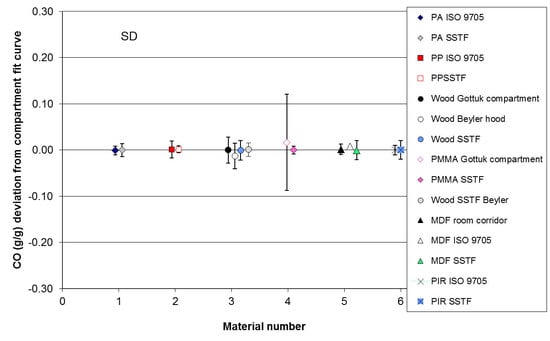

- smoke

- combustion

- biobased polymers

- biobased flame retardants

Related Special Issues

- Advances in Flame Retardant Polymers in Polymers (7 articles - displayed below)

- Recent Advances in Flame Retardancy of Textile Related Products in Polymers (16 articles - displayed below)

- Flame Retardancy of Polymeric Materials in Polymers (19 articles - displayed below)

- Flame Retardancy of Polymeric Materials II- Bio-Inspired and Environmentally-Benign Formulations and Methods in Polymers (10 articles - displayed below)

- Flame Retarded Polymers and Composites in Polymers (4 articles - displayed below)

- Advances in Flame Retardant Polymeric Materials in Polymers (12 articles - displayed below)

- Assessment of the Ageing and Durability of Polymers in Polymers (195 articles - displayed below)