Sustainable Polymeric Materials from Renewable Resources (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Biobased and Biodegradable Polymers".

Viewed by 153343Editor

Interests: sustainable industrial chemistry; green engineering; monomers and polymers from renewable resources; polymer nanocomposites; polymer recycling; materials characterization

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

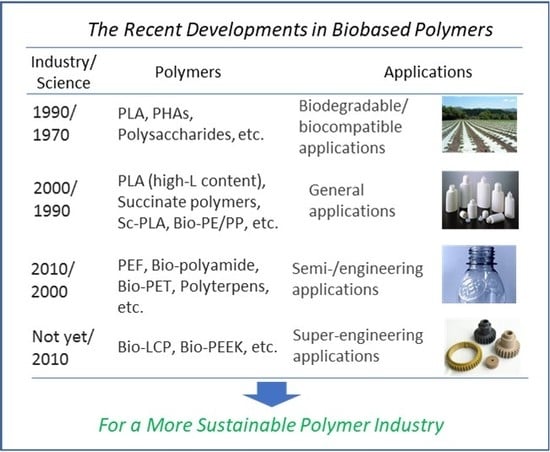

Naturally occurring polymers were among the first materials used by men. The modification of polymers from renewable resources, such as casein, natural rubber, and cellulose, was applied in the 19th century to obtain useful polymeric materials. Synthetic polymers dominated over the past few decades. Today, there appears to be a continuously growing interest in the development of sustainable, safe, and environmentally friendly plastics from renewable resources as a result of increasing concerns regarding the depletion of fossil resources, disposal, and related issues.

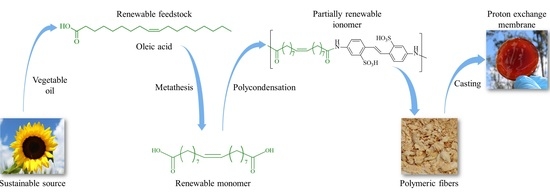

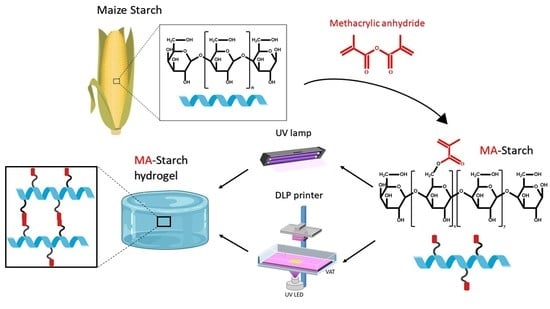

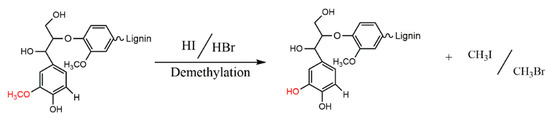

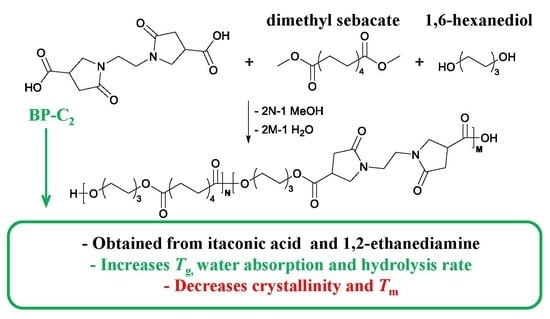

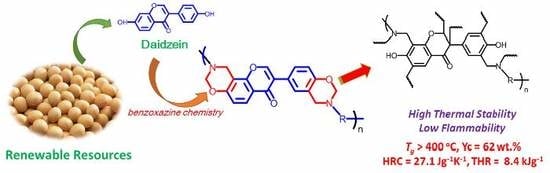

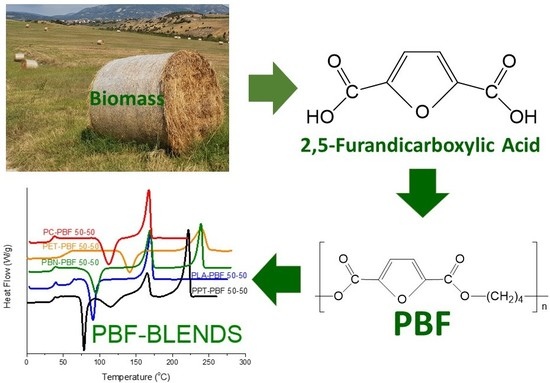

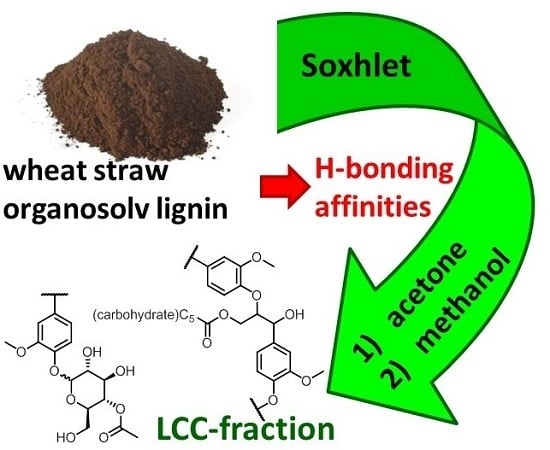

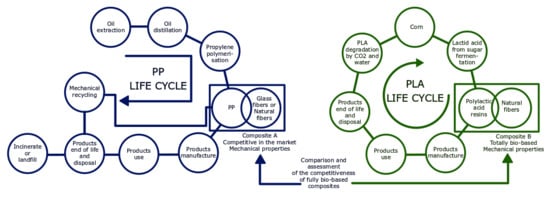

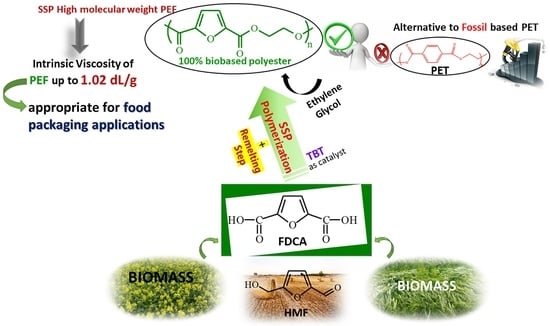

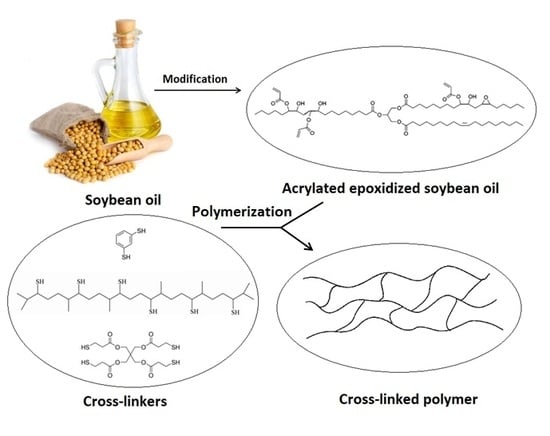

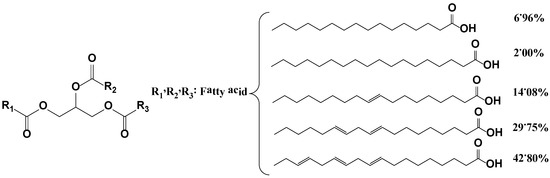

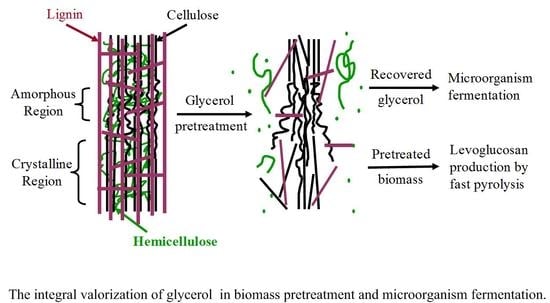

Although there are several options to produce energy from renewable resources, the only alternative to fossil-based materials is biomass. The application of the biorefinery concept and the green chemistry principles in ecologically benign materials production opens a new era. Generally, three different routes can be followed in order to arrive to bio-based polymers. The first pathway involves the chemical modification of natural polymers, such as starch, cellulose, or chitin. The second route is associated with the isolation or synthesis of bioplastics from biomass (lignin, cellulose, starch, plant oils) through a two-step process, involving firstly the preparation of drop-in (traditional) monomers, e.g., ethylene, 1,2-ethanediol, or terephthalic acid, or of novel monomers, such as lactide or 2,5-furandicarboxylic acid, and then the polymerization of these monomers to produce bio-based plastics. Amongst bioplastics, bio-polyethylene (bio-PE) or bio-poly(ethylene terephthalate) (bio-PET) are currently available. On the other hand, highly promising new polymers, such as poly(lactic acid) and poly(ethylene 2,5-furandicarboxylate) (PEF), or even thermosetting polymers can be synthesized using renewable sources.

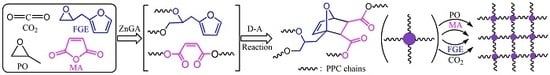

Finally, a third route involves the use of carbon dioxide in polymer synthesis. The first example is the production of polymer through photosynthesis or in microorganisms, e.g., biosynthesis of poly(hydroxy-alkanoate)s. Furthermore, CO2 can also be used in the preparation of non-isocyanate polyurethanes.

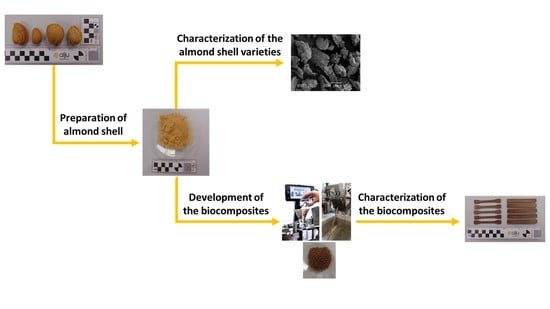

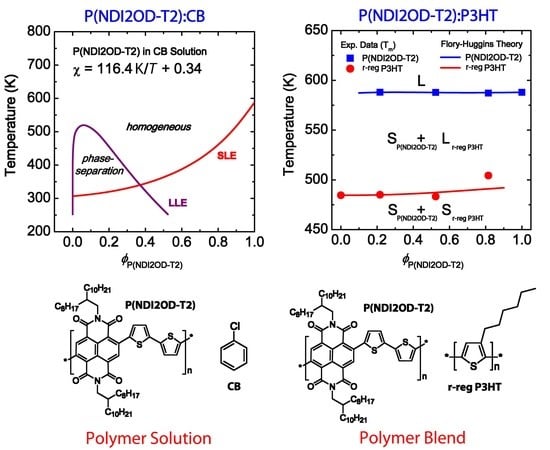

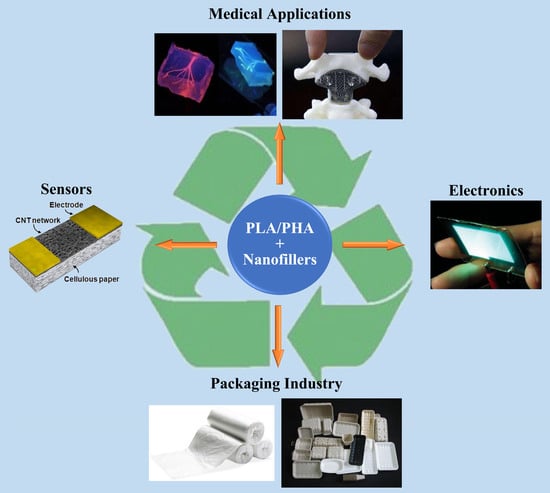

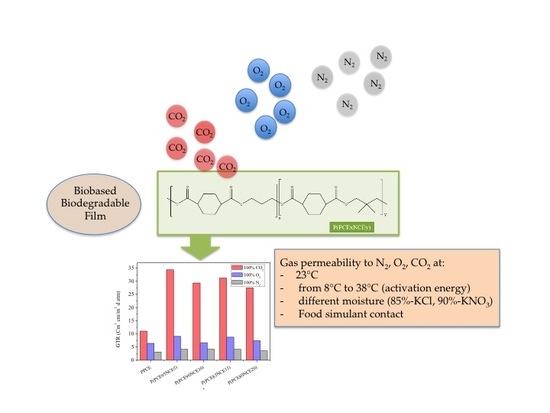

Apart from the use of proper monomers and the subsequent homopolymer production, copolymerization, blending, and the use of bio-based additives, like lignocellulose fibers for biocomposites, are considered the four main strategies for obtaining bio-based sustainable polymeric materials with tailored properties. Among polymers from renewable resources, there are many recyclable, yet nondegradable homopolymers synthesized from biomass derived monomers (PEF, bio-PE, bio-PET), but there are also biodegradable polyesters, including poly(lactic acid) (PLA), poly(β-hydroxybutyrate) (PHB), poly(butylene adipate) (PBA), poly(butylene succinate) (PBS), and others.

In this collection, an attempt is made to follow the current progress in the production of sustainable polymeric materials from renewable resources, starting from biomass-derived monomers and then extending in the synthesis, properties, uses, and applications of homopolymers and copolymers, but also blends and composites from renewable resources.

Prof. Dr. George Z. Papageorgiou

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- sustainable materials

- bio-based polymers

- green chemistry

- biodegradable polymers

- biopolymers

- bioplastics

- biorefinery

- ecologically benign materials

- renewable resources

- renewable monomers

- 2,5-furandicarboxylic acid

- poly(ethylene 2,5-furandicarboxylate)

- poly(lactic acid)

- vanillic acid

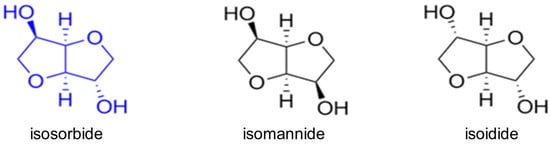

- isosorbide

- succinic acid

- chitosan

- bionanocomposites

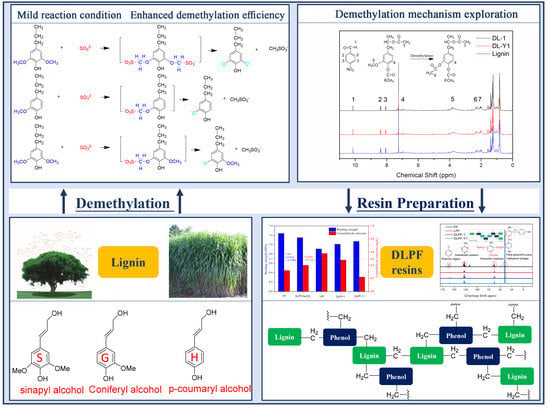

- lignin

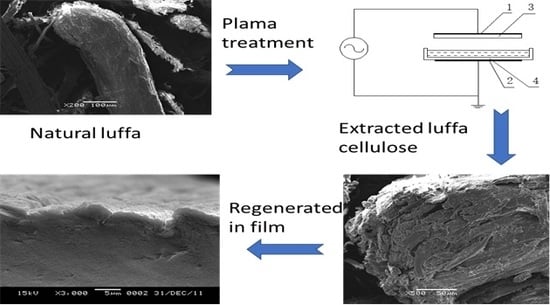

- cellulose

Related Special Issues

- Polymers from Renewable Resources in Polymers (35 articles - displayed below)

- Bio-Based Resins and Crosslinked Polymers from Renewable Resources in Polymers (12 articles - displayed below)

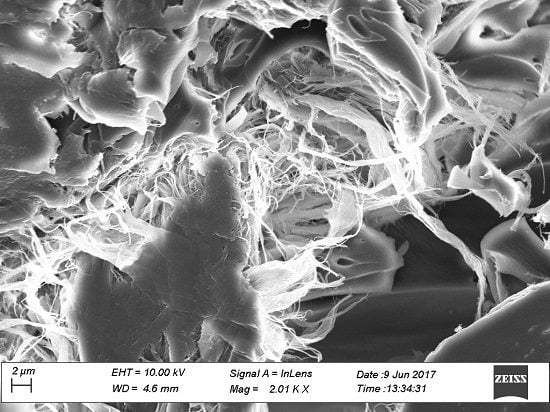

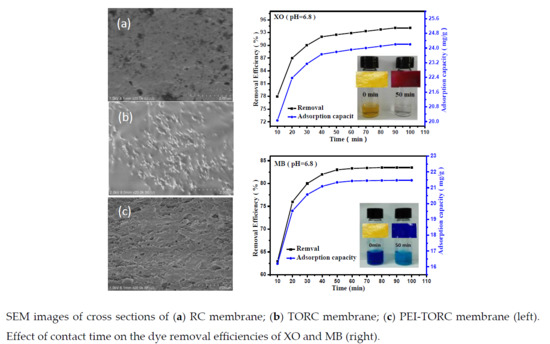

- Porous regenerated cellulose (RC) membranes were prepared with cotton linter pulp as a raw material. These membranes were first oxidized on both sides by a modified (2,2,6,6-tetramethylpiperidin-1-yl)oxyl (TEMPO) oxidation system using a controlled oxidation reaction technique. Then, the oxidized RC membranes were functionalized

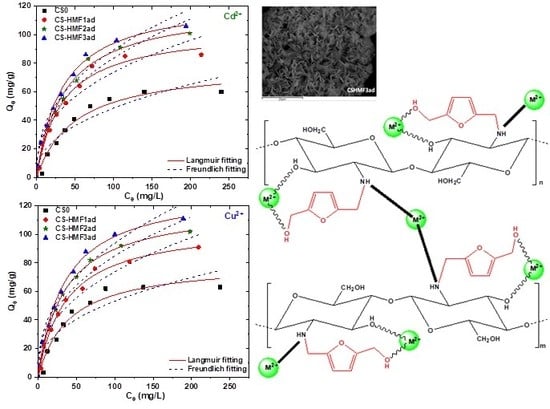

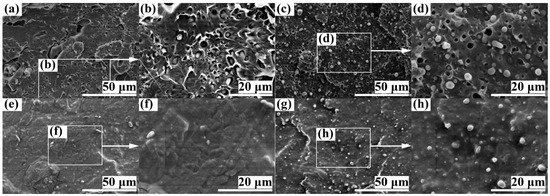

- Porous regenerated cellulose (RC) membranes were prepared with cotton linter pulp as a raw material. These membranes were first oxidized on both sides by a modified (2,2,6,6-tetramethylpiperidin-1-yl)oxyl (TEMPO) oxidation system using a controlled oxidation reaction technique. Then, the oxidized RC membranes were functionalized with polyethylenimine (PEI) via the glutaraldehyde crosslinking method to obtain bifunctional (carboxyl and amino) porous RC membranes, as revealed by Fourier transform infrared spectroscopy (FT-IR), elemental analysis and zeta potential measurement. The scanning electron microscopy (SEM) and the tests of the mechanical properties and permeability characteristics of modified RC membranes demonstrated that the porous structure and certain mechanical properties could be retained. The adsorption performance of the modified membranes towards dyes was subsequently investigated. The modified membranes displayed good adsorption capacities, rapid adsorption equilibrium and removal efficiencies towards both anionic (xylenol orange (XO)) and cationic (methylene blue (MB)) dyes, making them suitable bioadsorbents for wastewater treatment.