- Article

The Role of Carbon Content in the Microstructural Evolution and Electrochemical Corrosion Performance of Steel Blades Processed by Clay-Coated Quenching: A Comparative Study

- Wei Wu,

- Lijuan Diao and

- Lizhong Wu

- + 2 authors

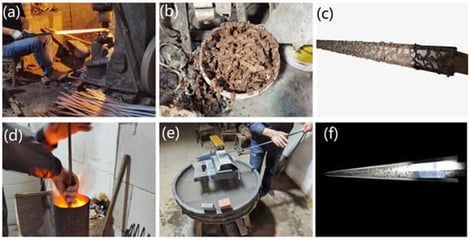

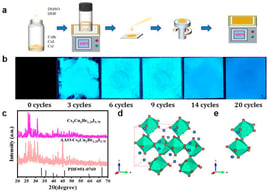

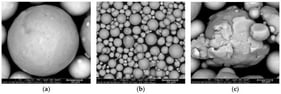

Coating a sword’s surface with clay before quenching in water not only produces distinctive patterns but also modifies its hardness and corrosion resistance. This study investigated two steel swords with differing carbon contents (L01 containing 0.69% C and L02 containing 0.98% C) subjected to the clay-coated quenching process to assess its impact on the blades’ microstructure, hardness, and corrosion characteristics. Samples from each sword underwent analysis through metallography, microhardness tests, electrochemical tests, and scanning electron microscopy. The investigation revealed that L02 comprising martensite, pearlite, retained austenite and carbides, exhibited a greater diversity of microconstituents than L01 containing martensite and pearlite. In addition, the hardness range of L02 (425~1050 HV) showed a broader hardness spectrum than that of L01 (HV 550~846), further illustrating that L02 possessed a higher degree of microstructural gradation and better balance of hardness and toughness. However, the electrochemical tests showed that each test area of L01 exhibited consistently lower corrosion rates than their counterparts on L02. The icorr values for L01 ranged from 5.12 to 8.29 μA·cm−2, while L02 had icorr values between 21.17 and 25.23 μA·cm−2. Importantly, the calculated Rp values across the different zones of L01 (ranging from 2338 to 4129 Ω·cm2) exceeded those of the corresponding zones of L02 (ranging from 502 to 816 Ω·cm2). The electrochemical impedance spectroscopy (EIS) data revealed that the Rct values for L01 (ranging from 2016 to 2837 Ω·cm2) were also greater than the corresponding values for L02 (range: 424~571 Ω·cm2). The data indicated that L02 exhibited inferior corrosion resistance compared to L01, attributable to its higher carbon content. This increased carbon content facilitated the development of a more heterogeneous and diversified microstructure during clay quenching, resulting in a greater electrochemical potential difference and subsequently accelerating corrosion. These insights delineate a distinct microstructure–corrosion relationship in gradient steel blades processed by clay-coated quenching and offer practical guidance for selecting carbon content to enhance both mechanical properties and corrosion resistance in traditionally crafted blades.

7 February 2026